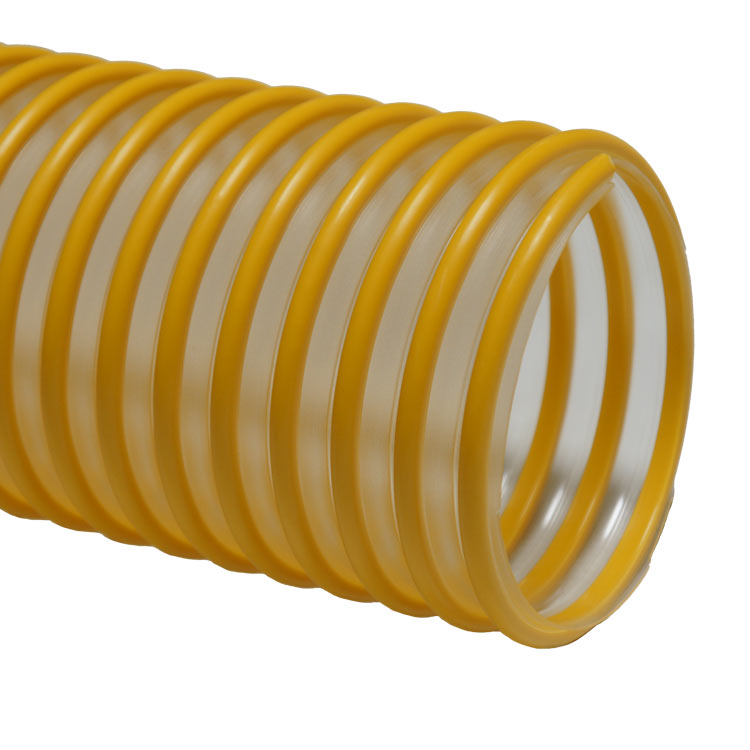

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Light-Duty Clear”

“Rhinoback”

What Is Abrasion Resistance?

Abrasion resistance is defined as the ability of a surface to withstand the wear and tear of friction caused by mechanical parts or the interaction of abrasive materials. Abrasion resistance is essential because many demanding industries require the transfer of harsh, irregularly shaped materials in large volumes, such as rocks, dust particles, and various debris from one point to another. From agricultural farms to residential and commercial applications such as leaf vacuuming and street sweeping, abrasion resistant flexible hoses are designed to optimize problematic tasks. When it comes to determining the factors of abrasive resistance for a flexible hose, there are three contributors to look for: material composition, fabrication method, and coating strength. The material composition of a flex hose is defined as the quantity of a material used in the production of a singular unit; the fabrication method refers to the process of shaping, cutting, and molding the materials into ducts, and the coating strength refers to the protective layer of the flex hose where it exhibits much of its durability.

How is Abrasion Measured?

There are several ways to test and measure the abrasion resistance of a material, such as the Taber Abrasion test, the Pico Abrasion test, and the Falling Sand Abrasion test. These tests are conducted under controlled conditions and are measured by the abrasive force, length of time, and the amount of wear inflicted on a material. The Taber Abrasion is one of the first and oldest methods to test the abrasive resistance of a material reliably. Originally founded in 1941 by Ralph Taber, the Taber Abrasion test determines a plastic’s resistance to abrasion. The test utilizes a machine with abrasive wheels and the material to be placed in between. After a specified number of cycles, the abrasive resistance is measured based on weight loss and thickness. The Pico Abrasion test is a method used to determine the abrasive resistance of surfaces and coatings. The material is mounted to a special wheel lined with abrasive material, and the wheel is then pressed against the material with a consistent force in either a linear or circular motion. After a predetermined number of movements, the test is concluded, and the abrasive resistance is measured by the depth of scratches and the amount of material that has been worn away. Lastly, the National Institute of Standards and Technology developed the Falling Sand abrasion test to measure the abrasive resistance of coatings. The test features a stream of sand to be poured onto a material until the stream wears away a considerable amount of the material, and the resistance is measured by the amount of time it took and the thickness of the material before and after the test. By finding out the resistance level of specific materials, hose manufacturers can design and build flexible hoses that not only cater to specific abrasive applications and industries but offer various customization options to those who need them.

“Smooth-Tube PU”

- Highly abrasive resistant, smooth interior hose.

- Excellent flexibility and puncture and crush resistant.

- External helix acts as wearstrip, protecting the outside of the hose.

- Excellent anti-microbial properties.

The “Smooth-Tube PU” material handling hose is a medium weight duct that is made up of polyurethane film. A great hose for dust collection and other material handling applications, it features a smooth interior that maximizes the level of flow in the tube. It is a very abrasion resistant hose thanks to its polyurethane makeup and its external wearstrip. Overall, this flexible ductwork is a great choice for your dust and material handling needs.

Consider carefully the benefits of having a smooth interior on a flexible hose for material handling. A smooth interior area means that the hose does not have any uneven ridges or corrugations. Such uneven surfaces can invite finer materials to get caught inside and clog up the flex duct. This can be a huge problem that will hinder the efficient functioning of your application. Particles will not get caught or form clogs on smooth interior surfaces of this hose due to its smooth bore. Inside, the material handling hose will benefit greatly from a superior and efficient level of airflow.

“Urethane Flex Heavy-Duty”

“Urethane Flex Static Dissipative”

“Urethane Flex Medium-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Heavy-Duty”

How Does a Flexible Hose Wear Down?

Ultimately, when a flexible hose rubs against objects for a prolonged period, it will eventually lose its abrasion resistance from standard wear and tear, and depending on the flexible hose’s application and industry, this can come in the form of one of two scenarios. The first scenario is internal wear damage, where the flex hose’s interior wears down from the transfer of abrasive materials over time. The second scenario is external wear damage, where the flex hose’s exterior obtains scratches and general wear and tear from external forces such as weather, handling, and environment. While this is a natural course of life for all flex hoses, flex fatigue is another factor that wears down a flexible hose. Flex-fatigue refers to the number of cycles a flex duct can be stretched and flexed until the duct’s material cracks. This is a normal occurrence in the industry and varies depending on the application and product choice. As all flex hoses will eventually ear down from flex fatigue, it is essential that you find an appropriate flexible duct for your application, whether it is transferring large volumes of fertilizer to sucking up abrasive materials for your workshop.

“Urethane Flex Heavy-Duty”

- Great abrasion resistance & high tear strength

- Superior chemical resistance

- Excellent flexibility

- Designed for applications with wide temperature ranges

The “Urethane Flex Heavy-Duty” material handling hoses are designed to work in severe abrasive and material transfer applications. This flex duct is made from polyurethane duct materials, making it very durable and flexible. The diverse properties of polyurethane make it the leading choice for engineers looking for long-lasting materials for their high load, high stress environments. Polyurethane routinely outperforms plastic and rubber in its overall ability to resist harsh environmental factors such as abrasion, heat, solvents, oil and acid. Because of the PU material used in these material handling hoses, these products feature fantastic tear strength while maintaining excellent flexibility.

This flex duct is also available in a clear color that is made with FDA acceptable materials. This flexible ducting’s heavy wall makes it an ideal choice for heavy-duty applications involving abrasives. The “Urethane Flex Heavy-Duty” material handling hoses are designed to work within wide temperature ranges. This dust collection hose works in temperatures ranging from -65 to +225 degrees Fahrenheit. Even when working in low temperatures, this dust collection hose maintains excellent flexibility.

“Urethane Flex Extra Heavy-Duty”

“Urethane Flex Heavy-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

“Urethane Flex Self Extinguishing”

“Urethane Flex Static Dissipative”

Screw Clamps

The Dangers of Static Buildup

Static buildup refers to the buildup of electrical charges within a flexible hose. As abrasive materials move through the hose, the material’s molecules collide and can potentially create a small electric charge, and if the electricity catches onto flammable materials, it can cause a chain reaction that could lead to explosions and large-scale fires. As some abrasive materials are naturally more volatile than others, and depending on the industry, static-related incidents are a common occurrence if proper safety measures are not taken. Agricultural grain handling is a perfect example of a flammable abrasive material that can cause problematic static build-up-related explosions if appropriate safety measures are not taken. According to OSHA (Occupational Safety and Health Administration), grain dust is a highly flammable material, and preventing grain dust-related explosions is naturally problematic because it is highly dependent on eliminating as many ignition sources and exposures as possible by controlling grain dust with dust collection equipment and flexible ducts. As such, static dissipative flex ducts are vital for reducing static buildup in abrasive ducting due to their utilization of materials such as a conductive elastomer coating.

Incorporating a conductive coating into static dissipative flex ducts allows the generated electrostatic energy to discharge and escape as abrasive materials are continuously transferred. Considering how many industrial facilities are surrounded with flammable material on a daily basis, sudden sparks from static buildups pose a severe threat and problem for every industrial facility and must be prevented in every applicable way. Beyond safety means, static dissipative hoses can also contribute to the efficiency of dust collection systems and similar applications. If left unchecked, static discharges can damage the electronic components of industrial machinery, fry the entire system, and render it useless. By using a static dissipative flex duct, you can protect your industrial machinery’s electrical components and ensure the safety of industrial facility workers.

“Neoprene Flex Conductive”

- Good crush resistance & tensile strength

- Neoprene coating offers excellent abrasion and chemical resistance

The “Neoprene Flex Conductive” static dissipative hose is recommended for industrial air movement, fume control, dust control, and light bulk material handling applications. The flex ducting is made from double-ply, neoprene coated polyester fabric that has been coated with a conductive elastomer. Flexible ducts with higher conductivity help reduce the danger of static buildup by allowing any electrostatic buildup to escape. If the net charges grow faster than a material can dissipate them, an electrostatic charge builds up. The excess charge can suddenly neutralize by a flow of charges to the surroundings, known as an electrostatic discharge or static spark. By super-heating the surrounding air and causing it to rapidly expand, the discharge is both visible and audible.

The neoprene coating of the hose material offers excellent abrasion and chemical resistance and is designed for abrasives, air, dust fumes and other materials. Each commercial hose is reinforced with a spring steel wire helix for good crush resistance and tensile strength. This product can handle both positive and negative pressure, please refer to the hose specification sheet for test data on specific sizes. This static dissipative hose has a working temperature range of -40 to +250 degrees Fahrenheit.

The Value of Food-Grade Hoses

For a flexible duct to be considered a food-grade hose, it must meet the required standards of the FDA (Food and Drug Administration). In compliance with FDA regulations, food-grade flex ducts must be made from non-toxic materials, exhibit excellent tensile strength and pressure capacity, and feature an odorless and tasteless design. Flexible materials such as thermoplastic rubber, PVC, and polyurethane are all FDA-approved materials often used to manufacture food-grade flexible hoses and ductwork for agricultural sectors. By utilizing FDA-approved flex ducts, agricultural facilities can transfer abrasive grains, straws, clippings, and feed in large volumes for barns and farmland and optimize their production rate. Flexible ducting options such as the “Thermoplastic Flex White” are a great example of a medium-weight FDA-approved hose that safely transfers materials through rough and unforgiving environments. As agricultural facilities use flexible ducts in various temperatures and settings depending on their respective climates, abrasion resistance should be one of many factors when choosing a flex duct that complies with FDA regulations. With that in mind, FDA-grade ducts must resist extreme temperature ranges, chemicals, heat, and UV rays to withstand the daily rigors of agricultural work.

“Thermoplastic Flex White”

- Good abrasion resistance

- Great moisture & UV resistance

The “Thermoplastic Flex White” is a medium-weight material handling hose that is great for abrasive, dust, and material collection applications. This product is specifically made from FDA acceptable hose material, which makes it suitable for food and drug-related applications. The thermoplastic rubber used in this product provides good chemical and heat resistance, and is also able to withstand higher temperatures than ordinary rubber products. Thermoplastic rubber refers to a class of copolymers that are made from a mixture of plastic and rubber. This combination results in a material that offers good chemical and UV resistance. This thermoplastic hose is also reinforced with a spring steel wire helix for added protection and stability. This resilient quality is important when using the food grade hose in rough and unforgiving environments. The smooth interior of this hose material allows for minimal friction loss and provides efficient airflow.

The “Thermoplastic Flex White” can be used as a dust collection hose in both high and low temperature environments. This thermoplastic hose has an operating temperature range of -40 degrees to +250 degrees Fahrenheit and is intended for environments that ordinary hoses cannot withstand. This product comes in a white color, which provides good visibility for food grade applications.

“Urethane Flex Light-Duty”

“Urethane Flex Extra Heavy-Duty”

What Duct Material Has the Best Abrasion Resistance?

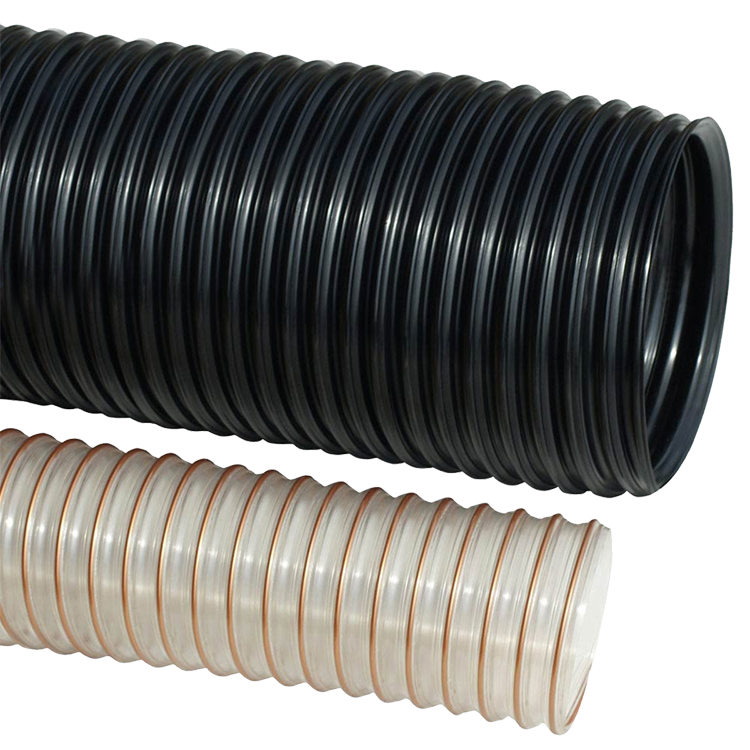

Urethane flex hoses are known for having the best resistance towards abrasion due to their material composition. Polyurethane is a plastic material invented in the 1930s by Dr. Otto Bayer; the material is used in a diverse range of products and applications, from coatings to adhesives. Depending on the application, polyurethane is an incredibly resilient material that can last for years. As a result, the resilient elastomer exists in various forms; however, in its relation to flex ducts and hoses, the material can be tailored to either a rigid or flexible structure when manufactured. Our “Urethane Flex” hoses come in different styles and weight applications, from light, medium, heavy, and extra heavy. No matter what kind of weight class you purchase, a “Urethane Flex” hose stands at the top of its class regarding abrasive resistance and overall durability. While a “Urethane Flex” hose is a more expensive option compared to their cost-effective counterparts, such as thermoplastic and PVC, they are undeniably the best option for all of your abrasive ducting needs and applications. “Urethane Flex” hoses are even available in different colored walls such as black, blue, and clear, and the clear translucent color can allow additional functionality by enabling machine operators to recognize and detect obstructions and debris buildup. However, it is essential to note that as the urethane hose wall thickness increases, they lose their overall flexibility due to polyurethane’s coating strength and composition. In exchange for a loss of flexibility, they gain additional strength that makes them more durable and suited for the most demanding environments.

“Urethane Flex Medium-Duty”

- Great abrasion resistance & high tear strength

- Superior chemical resistance

- Excellent flexibility

- Designed for applications with wide temperature ranges

The “Urethane Flex Medium-Duty” is a polyurethane duct designed for abrasives, dust, and material applications. These dust collection hoses are made from medium-weight polyurethane wall material reinforced with a bronze coated spring steel wire helix. The polyurethane hose materials used in this product give it excellent protection against chemicals and abrasion (external and internal).

This is our best selling polyurethane duct because it combines flexibility, chemical resistance, and abrasion resistance. The high tensile strength of polyurethane also assures reliability and durability when using this product. Because polyurethane duct is tough, it can have thinner gauged walls when compared to rubber or vinyl. This polyurethane duct also has excellent resistance to hydrocarbons, chemicals, ozone, bacteria, fungus, moisture, and skin oils. This material handling hose is available in clear, which utilizes FDA acceptable materials (ideal for food and drug applications).

“Thermoplastic Flex Extra Light-Duty”

“Thermoplastic Flex Heavy-Duty”

“Thermoplastic Flex Light-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Thermoplastic Flex Medium-Duty”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex White”

“Neoprene Flex – 2 Ply”

Is Neoprene Resistant to Abrasion?

One of the more expensive rubber options, neoprene flex ducts are an abrasive-resistant option that can cater to light to medium-weight applications such as residential and commercial yardwork. Neoprene is one of the first synthetic rubber products made and was developed as a stronger alternative to natural rubber and as a means to develop products that can resist water, oil, and solvent. While “Neoprene Flex” ducts are not as durable when directly compared to other materials such as polyurethane and thermoplastic, neoprene offers exceptional resistance against lightweight abrasive applications. However, one of the most notable features unique to neoprene is its overall flexibility and accessibility. While other materials, such as PVC and thermoplastic, offer a range of flexibility, they are limited due to the material’s composition. On the other hand, neoprene can be composed and coated in ways that offer more flexibility for abrasive ducts. Neoprene-coated hoses are available in different styles, types, and functions, exhibiting unique designs such as flame retardance, degradation resistance, and static dissipation. With all these features in mind, “Neoprene Flex” hoses are a durable, flexible alternative for those who are seeking options with their abrasive ductwork.

“Neoprene Flex – 1 ply”

“Neoprene Flex – 2 ply Heavy-Duty”

“Neoprene Flex Conductive”

“Thermoplastic Flex Heavy-Duty”

“Thermoplastic Flex Extra Light-Duty”

“Thermoplastic Flex Medium-Duty”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex White”

Which Is More Abrasion Resistant: PVC Hoses or Thermoplastic Ducts?

When comparing the abrasive resistance between two durable materials, such as thermoplastic and PVC, it is crucial to consider applications, the duct’s build, and the material’s composition. PVC is well known as a cost-effective option for all general-purpose applications due to its composition and accessibility. However, PVC falls short when compared to thermoplastic rubber because it possesses both rubber and plastic characteristics, making it more durable and flexible than PVC. Regarding abrasive resistance flex hoses, thermoplastic flexible ducts rival top-class materials such as urethane flex hoses due to their build and serve as a cost-effective alternative to urethane. Similar to “Urethane Flex” hoses, thermoplastic flex ducts come in four different wall thicknesses: Extra light, light, medium, and heavy, and as the wall thickness increases, the flexibility decreases. Thermoplastic flex hoses are sturdy, inexpensive outdoor hoses that balance flexibility, durability, lifespan, and cost-effective pricing and can withstand extreme temperatures in harsh environments and the daily rigors of demanding machinery.

“Thermoplastic Flex Light-Duty”

- Excellent compressibility and flexibility

- Designed for applications with wide temperature ranges

- Great moisture and UV resistance

- Excellent chemical resistance

- Smooth inner surface assures minimal friction loss and efficient air flow

“Thermoplastic Flex Light-Duty” is a lightweight flexible rubber hose that is recommended for light-duty air and material handling applications. This exhaust hose is made from medium weight thermoplastic rubber reinforced with a spring steel wire helix. Thermoplastic rubbers are a class of copolymers that possess both thermoplastic and elastomeric properties, generally made from a mix of plastic and rubber. The thermoplastic rubber material gives this product great chemical resistance and also provides a longer life in extreme hot and cold environments over standard rubber. The thermoplastic composition also provides excellent moisture, UV, and ozone protection to this industrial duct. Choosing this flexible ducting will offer the following benefits: excellent UV resistance, excellent flexibility, resistance to microbial attack, minimal moisture absorption, and broad temperature operating range. This product is also recyclable.

Smooth-Tube Flex Hoses

When it comes to abrasive ductwork, you not only require a flexible duct that can withstand all interior and exterior elements but also require a level of practicality. Our “Smooth-Tube” series is one of the most practical and handy ducting options due to its clear and smooth interior design. Built with a durable abrasive-resistant wall, the “Smooth-Tube” series features toughness that can withstand punctures, crushes, and impacts. However, the main feature of this flexible ducting option comes down to its clear, translucent design. This feature can allow its operators to detect clogs and blockages as abrasive materials are being transferred from one point to another. This design choice especially comes in handy for a wide range of sectors and industrial facilities that operate in significantly large volumes daily. Simply detecting a clog in a duct can drastically cut down the maintenance downtime and save operators hours from trying to figure out which part of the duct is clogged. The “Smooth-Tube” flex ducts can come in various material options, from standard PVC and thermoplastic rubber to polyurethane film. While the see-through feature is only available in PVC and polyurethane, the smooth interior part is available on all types of material, and this can significantly improve abrasive material flow through the duct because small particles and materials are not going to clump up and stick in a hose’s smooth interior. While the abrasive resistance of a “Smooth-Tube” is going to be dependent on your choice of material, the “Smooth-Tube” ducts are a practical choice for a range of abrasive applications.

“Smooth-Tube TPR”

“Smooth-Tube PVC”

“Neoprene Flex – 1 ply”

“Neoprene Flex – 2 ply”

“Thermoplastic Flex Heavy-Duty”

“Urethane Flex Heavy-Duty”

How Do I Choose an Abrasion-Resistant Hose?

When deciding upon an abrasion-resistant hose, the most essential factor that needs to be considered is the application. Commercial applications such as street sweeping, wood dust collection, and commercial vacuuming require a standard abrasive-resistant flex hose such as a thermoplastic duct due to its cost-effective design and durability. Industrial-grade applications such as agricultural facilities and industrial workshops require a “Urethane Flex” hose due to the material’s incredibly resilient nature and flexibility. Other crucial factors, such as the type of abrasive material, should be considered when choosing a flexible hose for your abrasive ductwork. If you do not acknowledge the flammable nature of your abrasive material, then proper safety measures cannot be taken, and it could lead to a scenario where the material unleashes a static charge that can cause a chain reaction and create a harmful explosion. By understanding the demands of your applications and machinery, you can make an informed decision to choose a flexible hose that can properly cater to all your abrasive ducting needs.

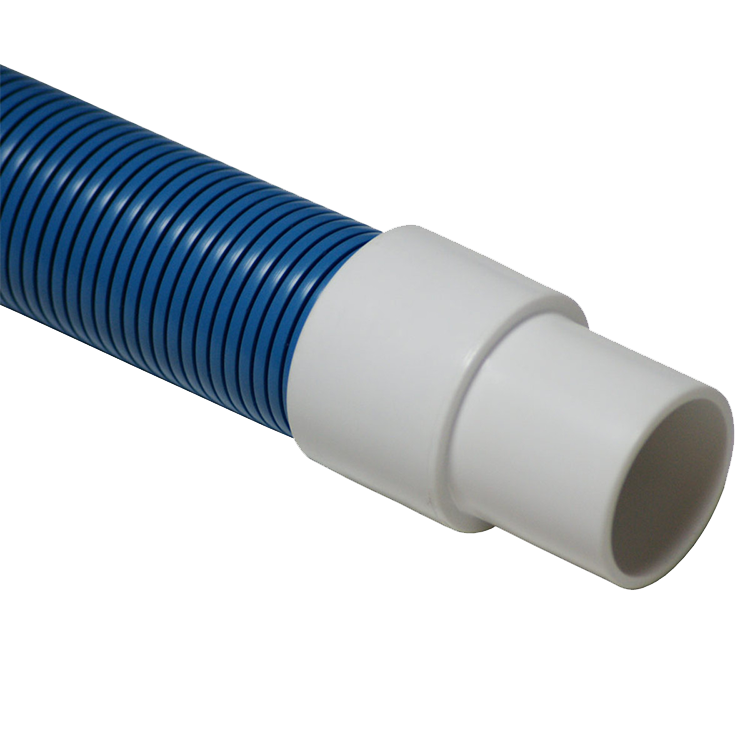

“PE Flex STM”

- Double profile I-Helix construction for easy movement on surfaces

- Ideal for both truck-mounted and portable carpet cleaning units

The “PE Flex STM” flexible industrial ducts are recommended for light bulk material handling applications. The orange or blue hose is made using a highly durable polyethylene copolymer. The hose wall has been reinforced with an integral polyethylene helix, designed for materials transportation. The double profile 1-Helix construction allows for easy movement on surfaces, which makes this vacuum hose ideal for both truck-mounted and portable carpet cleaning units.

These extraction hoses are flexible, crush resistant, and offer superior abrasion resistance. Abrasion can wear away the interior and exterior of a hose by scuffing, scratching, wearing down, marring, or rubbing it away. Abrasion is highly undesirable and can lead to premature wearing and failure. The construction of this hose provides great protection against these types of abrasion, making it ideal for most commercial applications. Additionally, the vacuum hose is designed to resist corrosion caused by the combination of hot water and chemical concentration of detergents. The “PE Flex STM” flexible duct-work is available in both 1.5 and 2 inch internal diameters with tolerances between -0.00 to + 0.050 Inches. The smooth interior of the flexible industrial ducts allows for an efficient level of air to flow through it. This means that both hose sizes are capable of handling a full vacuum. This allows for its use in a wide variety of industrial and commercial applications. These extraction hoses have a wide range of working temperatures from – 40 Fahrenheit to +160 Fahrenheit.