“Air Ventilator Orange”

“Air Ventilator Black”

What Is Ambient Air?

Ambient air or fresh air is what is drawn into the building or space from the outside and recirculated indoors. Moving fresh air into a building ensures that pollutants, contaminants, and toxic air are removed, and this fresh air may be heated or cooled during this process. While ambient air can vary in composition and quality depending on location, weather conditions, and pollution levels, it is still drawn into a building through ventilation systems such as air conditioners and HVAC systems. As such, ambient air is essential to ensure our indoor air environment is comfortable, livable, and pollutant-free. According to OSHA, the ideal office temperature should be between 68- and 76-degrees Fahrenheit, with humidity between 20% and 60%. Mild temperature variation may be healthy in a working environment, but exposing workers to extremely hot and cold climates can ultimately affect productivity. The Occupational Safety and Health Administration (OSHA) can’t completely resolve the temperature conflict in a workspace; however, a healthy and safe work setting is a reasonable demand. While the Occupational Safety and Health Administration (OSHA) cannot define one specific workplace temperature, they have defined a suitable range that satisfies comfort and workplace efficiency.

“Aluminum Flex 400”

Can a Lack of Ventilation Cause Health Problems?

According to the EPA (Environmental Protection Agency), if a room receives poor air circulation and ventilation due to an ineffective ventilation system, it can cause problems, such as the accumulation of pollutants and contaminants. Ventilating quality ambient air to your indoor space is essential for your health and making any indoor environment comfortable. Most pollutants originate from inside a building and can be generated periodically or continuously from indoor machinery or appliances, so proper ventilation and air control are necessary to prevent indoor air pollution. Pollutants such as allergens, carbon monoxide, dust, pollen, and mold spores can collect within confined spaces. The consistent buildup of some of these contaminants can turn into severe problems that can cause mold and mildew growth. Depending on the climate, these pollutants can grow exponentially and produce a strong, musty odor that can circulate throughout a building. As a result, anybody who is exposed to indoor contaminants for a period will encounter health-related problems such as allergies, asthma, headaches, and general discomfort. Ventilating these contaminants out of a building with steady and reliable ductwork can not only prevent these pollutants from cultivating, but it can ultimately reduce the likelihood of respiratory problems, allergies, and other health issues from developing. In doing so, proper indoor ventilation and ductwork can create a clean, healthy environment that can contribute to the overall well-being of the people inside.

“Aluminum Flex 280 – Compressible”

- Designed for extreme temperature applications

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The Aluminum Flex 280 – Compressible comes prefabricated in a variety of different inside diameter (I.D.) sizes: 3″, 4″, 5″, 6″, 8″, 10″, and 12″. The walls of this flexible metal tubing are 0.1 to 0.11 mm. thick, and it has an I.D. tolerance of 0 to 0.1 inch. Its end finishes are plain cut, and it comes in a classic, metallic-silver colorway. This flexible metal hose is also semi-rigid, which means that, once you bend it into a certain position, it will stay that way without any added support. Of course, you can bend it again to reform the duct into a different position. In sum, it’s likely that you will not need to use any accessories such as elbows to fit your Aluminum Flex 280 – Compressible into looping or bent positions.

This flexible metal duct is designed with air and fume ventilation applications in mind, thus making it well-suited for a variety of residential, commercial, and industrial applications—especially those that intend to transport high-temperature matter. Wood stoves, for instance, need to properly ventilate hot smoke from the wood they burn. The Aluminum Flex 280 – Compressible is a natural fit for these kinds of applications—especially since, oftentimes, a wood stove’s exhaust duct must navigate a circuitous pathway to reach the destination where it expels the stove’s fumes. Other common uses for this metal flex-duct include chemical fume ventilation, circuit board cooling, and air conditioner ducting, among other things.

“Tornado Flex In Sack”

“Tornado Flex Insulated AD”

“Tornado Flex”

“Wind Handler Insulated TU”

“Wind Handler WS”

“Wind Handler”

Screw Clamps

What Is the Difference Between Ventilation and Extraction of Air?

Both systems use fans; however, extraction exhaust equipment pulls pollutants from the air by venting out indoor air while ventilation fans cycle in fresh air into an enclosed space from the exterior of the building. Ventilation and extraction may seem very similar, but their distinct functions and designs make them different. The purpose of ventilation is to provide a consistent flow of fresh ambient air throughout a building’s ductwork that circulates stale air and removes pollutants. Meanwhile, extraction focuses on removing gases, fumes, and odors from an area and expelling them to a safe location. While exhaust fans and smoke ducts play a crucial role in commercial and industrial applications, they are only designed to extract contaminated air and do not bring any fresh air in. Without fresh air being ventilated in a building either by ducts or flex hoses, contaminants such as carbon monoxide (C.O.), nitrogen dioxide (NO2), fine and ultrafine particles, polycyclic aromatic hydrocarbons (PAHs), and formaldehyde can cause headaches, fatigue, queasiness, and eye, nose, and throat irritation to everyone within the vicinity. In more severe cases, non-ventilated rooms and areas can develop long-term health problems such as lung disease, cancer, and respiratory infections. This is why ventilation is especially essential in most applications because it can bring in fresh air to workers and prevent long-term health problems from emerging.

“Air Ventilator Orange”

“Air Ventilator Black”

“Air Ventilator Insulated”

What Are the Benefits Of Insulated Ducting?

The primary purpose of thermal insulation in ducting is to retain and control temperature flow throughout a building and to prevent heat loss. When it comes to ventilating ambient air throughout a building’s ductwork and HVAC system, insulated flexible hoses and ducts are the best options to ensure that your climate-controlled air is being maintained and transferred to every room in the building. Most common forms of insulation are made from cellulose, fiberglass, and mineral wool, and these materials create a barrier that impedes and slows the movement of conductive and convective heat flow. Depending on the type of insulation, insulated hoses can withstand extremely high and low working temperatures, making them the most suited to handle various residential, commercial, and industrial applications. Insulated ducts, especially flexible ducts, are a popular choice to regulate heat ducting and air conditioning ventilation because they significantly reduce energy waste, potential air leakage, and overall noise. While non-insulated ducts may seem like an affordable alternative to your ducting and ventilation needs, using a non-insulated flex duct can lose up to 40% of generated heating and can ultimately cause heating systems to operate 50% harder to make up for the loss, and as a result, it will increase utility and energy costs due to heat loss. Heat loss refers to the loss of thermal energy as it is being transferred throughout a building’s ductwork. Approximately 25%-40% of heat is lost in a building’s ductwork due to factors such as the number of bends in a building’s ductwork and their overall length. The best way to prevent and combat such a loss is to utilize insulated ducts with a significantly high R-value. As a result, insulated flexible hoses and ducts are the best material for ambient air ventilation and serve as the best material for most standard temperature-regulating ductwork.

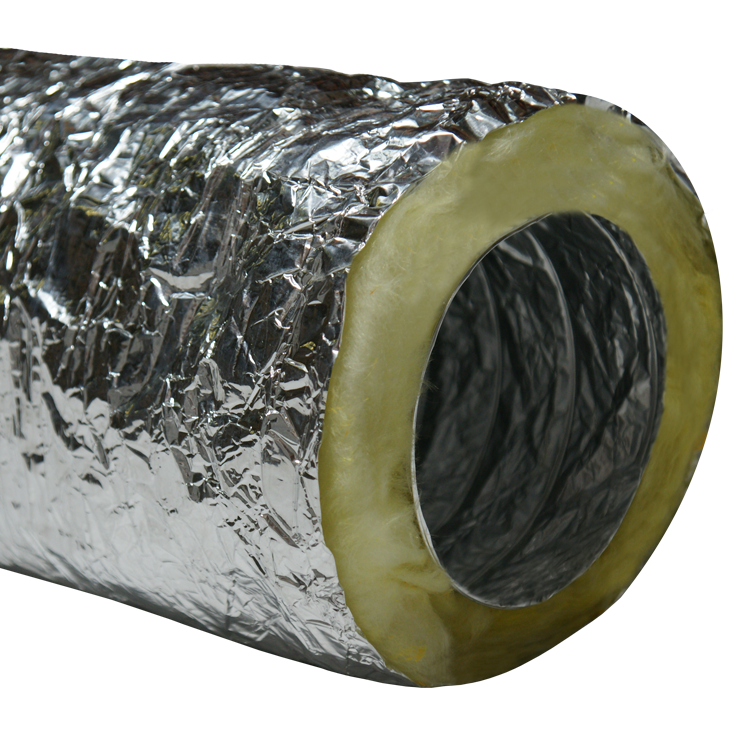

“HVAC Insulated-Flex”

- Ideal for use for permanent and mobile air condition units

- Compressible and easy to transport

- Insulation maintains temperature of air inside hose

- Provides acoustical as well as thermal insulation

The “HVAC Insulated-Flex” hose is a superb choice for HVAC air duct use. These ducts for air conditioning applications are double-ply insulated flexible hoses that are made of aluminum foil and PET film layers. Each HVAC flexible duct is insulated with glass wool material. This product is beneficial to consumers because of its affordable price point. It is definitely a more cost-effective HVAC ducting option than other competing hoses. It will also look good in any setting that it is placed in thanks to the shiny silver insulation material on the outside of the hose.

The insulated nature of this portable air conditioner hose allows it to operate in both high and low temperatures. The double-ply insulated material of this HVAC air duct allows it to function well in temperature ranges between -20° F and 160° F. Whether your application involves the transfer of cold air or hot air, these HVAC ducts for air conditioning uses can maintain their structural integrity with ease. The insulated material also helps maintain the temperature of the air that is present inside the hose.

“Tornado Flex Insulated AD”

“HVAC Insulated-Flex”

“Tornado Flex Insulated AD”

“Wind Handler Insulated TU”

What Is R-Value?

The R-value is a unit of measurement that determines how effective an insulated product’s ability is to resist heat flow. If a duct has a high R-value, its insulation has a high thermal resistance and is highly effective in reducing heat loss for long periods. On the other hand, if a duct has a low R-value, its insulation has a low thermal resistance, and heat loss will likely occur as it is transferred from one point to another. To find the R-value for your insulated duct or flexible hose, it is usually found on the product’s manufacturer’s documentation. If it is not there, there are several ways to determine an insulated material’s R-value, from the complex to the simple. The general formula to determine the R-value is to divide the thickness of the insulation material (either in meters or inches) by the rate at which heat flows through it (either by watts per square meter or BTU per hour per square foot). By calculating the R-value with this formula, you can accurately measure the thermal resistance of your product’s insulation. However, if you require a much simpler way to determine an insulated duct’s R-value, then the general rule of thumb is to examine the thickness of the insulation material. If the material is thick, your duct’s insulation has a high R-value. If your duct or flexible hose has a low R-value due to its initial design, then a reliable, straightforward way to increase its thermal retention is by adding extra layers of insulation, making it more resistant to heat flow. While this can increase the overall weight of your duct and flex hose, recent advancements have made insulated materials lighter and easier to install.

“Wind Handler Insulated TU”

- Good for air handling applications.

- High tensile strength

The “Wind Handler Insulated TU” insulated ducting is made from two single-ply neoprene coated yellow polyester fabric plies with an insulated barrier in-between and is designed for air applications. The neoprene coating is part of the synthetic rubber family that is produced by the polymerization of chloroprene. This neoprene coating exhibits good chemical stability and maintains flexibility over a wide temperature range. Neoprene is a synthetic rubber which exhibits high tensile strength, allowing this flexible air duct to flex and compress without causing damage to the hose wall. This high temperature insulated ducting is also reinforced with a spring steel wire helix and an external wear-strip. The duct materials allow this product to be flexible and compressible while maintaining strength and durability. This insulated duct is recommended for industrial air ventilation applications that require durability.

The “Wind Handler Insulated TU” insulated ducting is made to order in custom lengths. This hose comes in yellow and features the black external wear-strip. The flexible air duct features standard cuffed ends, and belted finishes are also available for an additional charge. Available ID sizes for this insulated duct range from 4 inches to 24 inches and custom sizes up to 48 inches are available upon request. This product is great for use in air applications such as use in A/C ventilation, HVACs, mobile cooling units, plastic bag machines, shipyard work, and tent cooling.

“Tornado Flex In Sack”

“Tornado Flex Insulated AD”

“Tornado Flex”

How to Measure Ductwork

How Do You Measure Ductwork?

The best way to measure ductwork is by finding its inside diameter. The inside diameter determines a duct’s size by measuring a straight line from one point of a duct’s inner wall, through its center, and to the opposite inner wall. Whether you choose traditional rigid ducting or flexible hoses, determining the inside diameter (I.D.) size is the best and most accurate way to measure your ductwork. It should not be confused with the Outside Diameter (O.D.), which measures a straight line from the outside edge of a duct across the center and to the opposite outer edge. A common misconception when measuring flex hoses is that the best way to measure them is by finding their circumference. The circumference refers to the enclosed boundary of the circle, and the main reason why measuring the circumference of a flexible hose is inefficient is because it only refers to the distance of the outside perimeter of a flexible hose. As a result, simply finding the circumference doesn’t account for the channel size of the flex hose where air, fumes, and materials flow through. If you measure a duct or a flex hose by its circumference, you risk purchasing a flexible hose or duct that does not fit the channel size of your machinery and ventilation system.

Screw Clamps

What Does CFM Mean In Ventilation?

CFM, or “Cubic Feet per Minute,” is a unit of measurement that quantifies the volume of air being moved or exchanged for each minute of its movement. To accurately measure and calculate the required CFM for a ventilation system, you typically need to use an airflow measurement instrument such as an anemometer or a flow meter, and various factors must be considered, such as room size, occupancy, ventilation standards and codes, and the size and length of the ductwork. However, while measuring CFM through a flex hose or ductwork can be a complex calculation, the general rule of thumb is that if your application requires you to move a substantial volume of air quickly, you would need a high CFM to ensure effective air movement. So, machinery such as utility fans, bathroom fans, air compressors, and smoke extraction systems would require a high CFM to ensure that air flows through where it needs to be quickly and efficiently. On the other hand, residential heating and cooling, indoor agriculture, and commercial refrigeration require a low CFM to minimize energy consumption and maintain a comfortable and temperature-controlled environment. Accurately measuring CFM ensures that HVAC and ventilation systems perform to their intended purposes and prevent inadequate or excessive airflow issues.

“PVC Flexduct General Purpose Blue”

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Light-Duty Blue”

“PVC Flexduct Light-Duty Clear”

How Do I Choose a Flexible Hose for Air Ventilation?

Any of our flexible ducts can be used for an air ventilation duct, but you must choose a flexible hose that is made from a suitable material. All our flexible ducts used in air movement are roughly separated into the following categories:

- Metallic (Aluminum or Stainless Steel)

- PVC Coated Poly-Fabric Hoses

- Neoprene Coated Poly Fabric Ductwork

- Smooth Bore Ducting

- Flexible PVC Hoses

- Insulated Flexible Ducting

Metallic Flex Hoses (Aluminum or Stainless Steel)

Flexible hoses made from metals have excellent durability and exhibit exceptional resistance against punctures and extreme temperatures. Since metals such as aluminum and stainless steel can maintain their shape when bent, metallic flex hoses are great semi-rigid ducts that are extremely handy in environments that require a precise, sturdy ductwork. Due to their composition, metallic flex hoses are resistant to weathering and most corrosive fumes and chemicals. In fact, aluminum and stainless-steel flex ducts are far more durable than their PVC or Neoprene counterparts, making them an excellent option for various applications. Metals have a more comprehensive range of temperature resistance in which they operate. Depending on the style selected, our aluminum flex ducts can handle temperature maximums of 280- or 400-degrees Fahrenheit, perfect for residential and commercial applications. Meanwhile, we offer two stainless steel hoses, one that can withstand maximum temperatures of 800 degrees Fahrenheit and another that can reach 1650 degrees Fahrenheit, which are great for any industrial application.

“SS-Flex 800”

“SS-Flex 800”

- Lightweight & hand bendable allowing for elbows and turns to be formed easily during installation

- Resists metal fatigue, weathering, & moisture corrosive fumes & chemicals

The “SS-Flex 800” is a single-ply helically corrugated stainless steel hose with a four-ply finished seam that is folded flat and crimped, allowing for excellent tightness and strength. Unlike other forms of steel, stainless steel does not readily corrode, rust or stain when it comes into contact with moisture. Stainless steel is essentially low carbon steel, which contains chromium at 10% or more by weight. It is this addition of chromium that gives the steel its unique corrosion resisting properties. This flexible steel hose is also very lightweight allowing for easy installation. The hose’s flexibility allows for this stainless hose to be hand bendable, allowing you to easily create elbows and turns during installation. Because the stainless steel is resistant to weathering, moisture, corrosive fumes, and chemicals, this product exhibits excellent life.

The “SS-Flex 800” stainless steel hose is also very resilient to high and low temperature extremes. This flexible high temperature hose has a temperature range of -400 degrees to +800 degrees Fahrenheit. This truly wide temperature range gives this flexible steel hose great versatility, allowing it to be used in a large variety of industries. Stainless steel’s resistance to corrosion and staining, low maintenance and familiar luster, makes it an ideal material for many applications. This flexible high temperature hose is also an aesthetic choice in commercial kitchens with exposed fume hoods.

“Air Ventilator Black”

“Air Ventilator Orange”

PVC Coated Fabric Hoses vs. Neoprene Coated Fabric Ductwork

Coated poly-fabric hoses are popular flex hoses that are durable and affordable. These hoses are designed to be very sturdy due to their cross-linked fabrics coated with PVC or Neoprene. The cross-linked nature of the materials gives this flexible duct excellent flex-fatigue, and as a result, both vinyl and neoprene-coated ducts are highly compressible (i.e., 9 to 1 compression ratio) and very flexible. Hence, they can be compressed, stretched, and flexed repeatedly without cracks, rips, or tears. This feature alone is especially important for applications requiring continuous flexing and applications requiring hoses to be consistently moved from one location to another. PVC or vinyl-coated fabric hoses are an affordable option that can handle temperatures up to 180 degrees Fahrenheit. Our “Air Ventilator” ducts and “Wind Handler” air hoses fall into this category and are undoubtedly the best option for transferring significant volumes of air. Meanwhile, neoprene-coated fabric ducting (i.e., “Tornado-Flex” series of air vent ducts) can handle temperatures of up to 250 degrees Fahrenheit and should be considered when dealing with extreme temperatures within this range.

“Air Ventilator Heavy-Duty”

- Heavy-weight duct hose

- Highly compressible and easy to transport

The “Air Ventilator Heavy-Duty” ventilation hose is a highly durable air ventilation duct that is well suited to industrial air movement applications. This flexible ventilation duct is made with a thick PVC vinyl coated polyester fabric that is reinforced with a spring steel wire helix and external wear-strip. These physical features make it ideal for withstanding the rigors of industrial ventilation ducting. The spring steel wire helix in each of these heavy-duty ventilation ducts gives them a stronger form and a degree of flexibility. It can help prevent the air hose from being crushed or deformed. The external wear-strip on the outside of this durable air ventilation hose is meant to provide an added layer of protection against physical abrasion. With these great structural components, this heavy-duty flexible ventilation duct will last for longer periods of time.

The biggest differentiator that separates these air ventilation ducts from others is its thicker and heavier PVC fabric material. Although the spring wire helix allows for easier compressibility and transport, this ventilation ducting is heavier than its standard counterparts. The thick material makes it well suited to use as industrial ventilation ducting where physical durability and longevity are a necessity. Naturally, the thicker the material, the better it can handle rough physical working conditions. It can also handle high and low temperature situations, with a working range between -20° F and 180° F. Use this ventilation hose for heavy-duty applications.

“Wind Handler Insulated TU”

“Wind Handler WS”

“Wind Handler”

Smooth-Tube or Smooth Bore Ductwork

Our “Smooth-Tube” series should be considered if your application requires you to move significant volumes of heavy dust and materials through ducts. The ducts in the “Smooth-Tube” series are durable flexible air ducts with an ample wall thickness that protect these hoses from physical damage such as external objects or abrasive materials. Most flexible air ducts are designed with corrugations, and this design choice makes it possible for flex ducts to become compressible and malleable. However, the corrugated portions within the walls are where dust and debris can accumulate, and if it is not routinely cleared, it can lead to blockage and clogs that slow down your work. In response, the “Smooth-Tube” series was created and ensures that you will always have the maximized level of airflow. While “Smooth-Tube” flex ducts are a more expensive and less flexible alternative than other options, they should only be used in ventilation applications where the environment and material are abrasive.

“Smooth-Tube PVC”

“PVC Flexduct General Purpose Blue”

“PVC Flexduct General Purpose Clear”

Flexible PVC Duct Hoses

PVC duct hoses are a popular choice because of their cost-effective design and accessibility. PVC is a durable material that is frequently used for commercial and industrial ductwork. The material’s natural resistance to abrasion, weathering, chemicals, and moisture makes it perfect for applications in strenuous environments. However, PVC duct hoses can also be used for residential applications such as portable air conditioning and duct cleaning. Due to their accessibility, they can come in a wide variety of inside diameter sizes (I.D.) and colors like clear or black, giving you options in both size and aesthetic. As a result, PVC flexible ductwork is unlike any other flexible hose; they are ultra-affordable, ultra-flexible, and available in a wide variety of lengths, thicknesses, and ID sizes. Regardless of your application, a PVC flexible air duct is one of the most adaptable duct hoses you can depend on for your air, dust, and fume ventilation needs.

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Light-Duty Clear”

“Tornado Flex Insulated AD”

“Wind Handler Insulated TU”

Insulated Air Duct Hoses

Using an insulated air duct hose is the best ductwork option if you want the most optimal performance from your HVAC system. While opting for a non-insulated flex hose may seem like a cheaper, cost-effective alternative, non-insulated flex hoses typically generate higher long-term costs due to heat loss and maintenance. In fact, insulated flex hoses can not only prevent heat loss from occurring, but they can enhance the overall energy efficiency of your HVAC system and significantly lower your energy costs. Another considerable benefit of insulated air duct hoses is their long-lasting padded design. As climate-controlled air is being transferred throughout a building’s ductwork for long periods, the insulated padding makes insulated flex hoses less susceptible to standard wear and tear that is usually seen in non-insulated hoses. Depending on your application and choice of product, insulated air duct hoses can extend the lifespan of your HVAC components by placing less stress on the machinery and its overall performance.

“Air Ventilator Insulated”

- Ideal for use for permanent and mobile air condition units

- Compressible and easy to transport

- Insulation maintains temperature of air inside hose

- Very cost effective insulated duct

The “Air Ventilator Insulated” ventilation ducts are made from two single-ply PVC fabric layers, plus one layer of PET film with a cotton barrier meant for insulation. The insulated barrier in this flexible ventilation ducting hose makes it ideal of air movement applications. It is compressible and can be easily moved around, thus making it good for either permanent or temporary air conditioning uses. Primarily meant for residential or commercial level of air ducting and ventilation, it has a shiny metallic silver appearance that allows it to bring a sleek and professional look to the job.

This insulated flexible ventilation ducting is made to operate in both high and low ambient temperatures. These vent hoses can function well in temperatures ranging between -20° F and 180° Fahrenheit. A superior level of functionality in various temperatures is a key factor in any good air ducting and ventilation hoses. Whether your application sees a lot of very cold air or very hot air, or even both, these insulated ventilation ducts will be up to handling the task.

Can I Use a Flexible Hose for HVAC?

Flexible hoses are one of the best ductwork options for HVAC systems for their adaptability, flexibility, and reliability in a plethora of applications. Flexible hoses are a great alternative to traditional rigid ductwork because of their easy-to-install nature and design that doesn’t require connectors. Depending on your application, flexible hoses come in various types, styles, and materials. Insulated flex hoses, for example, are great for all climate control ventilation and standard residential air ducting due to their ability to retain heated and cool air for long periods. Meanwhile, hoses, such as neoprene-coated flex ducts, are incredibly durable and resistant to abrasive materials, which makes them perfect for industrial applications. Additionally, flexible hoses can be sold in customizable I.D. sizes, lengths, and colors, making them ideal if you want options in your potential ductwork. Ultimately, flexible hoses are an excellent viable option if you are looking for a semi-permanent solution to your air ducting needs, but you must incorporate the best type of flex hose that fits your machinery’s requirements to get the best effectual output.

“HVAC Ventilation-Flex”

- Compressible and easy to transport

- Provides acoustical as well as thermal insulation

The HVAC Ventilation Flex is a high-quality and affordable ducting hose which provides an excellent option for customers looking for air movement solutions. These durable HVAC ducts are designed specifically for the transfer of air, and they excel in applications including air conditioning duct work. The HVAC Ventilation Flex is a versatile and flexible HVAC duct which can be used in a range of different settings, from residential use to industrial applications.

These HVAC ducts are made using a combination of materials, including PVC, aluminum and a layer of PET film. The outer layer of the Ventilation Flex is a tough, gray-colored PVC, with a wire helix winding through it to provide additional strength and support to the body of the hose. On the inside of the hose, the inner walls are covered with silver aluminum.

The HVAC Ventilation Flex ducting is made to be used effectively in either mobile or permanent installations. These HVAC ducts are easy to handle due to their excellent levels of compressibility. The hose – which is available in standard lengths of 25 feet – has a 5 to 1 compression rate, allowing it to be reduced down to a fraction of its fully-stretched size. This makes it especially easy to transport or store. Customers can get the HVAC Ventilation Flex in a variety of diameter sizes too. It is offered with inner diameter measurements of 4”, 6”, 8”, 10” and 12”, with some additional custom sizes available depending on the order.