“Urethane Flex Medium-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Urethane Flex Light-Duty”

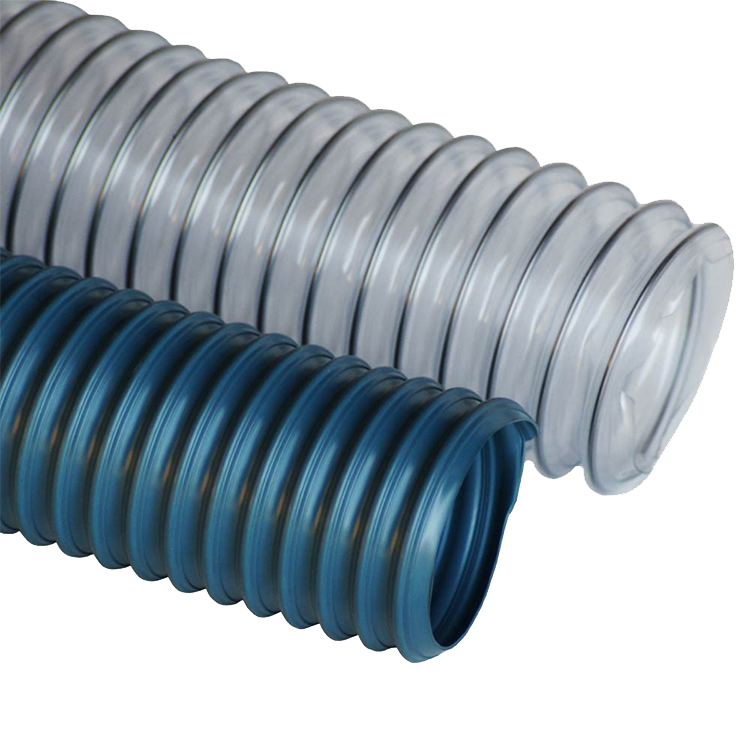

“PVC Flexduct General Purpose Clear”

“Urethane Flex Heavy-Duty”

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Clear”

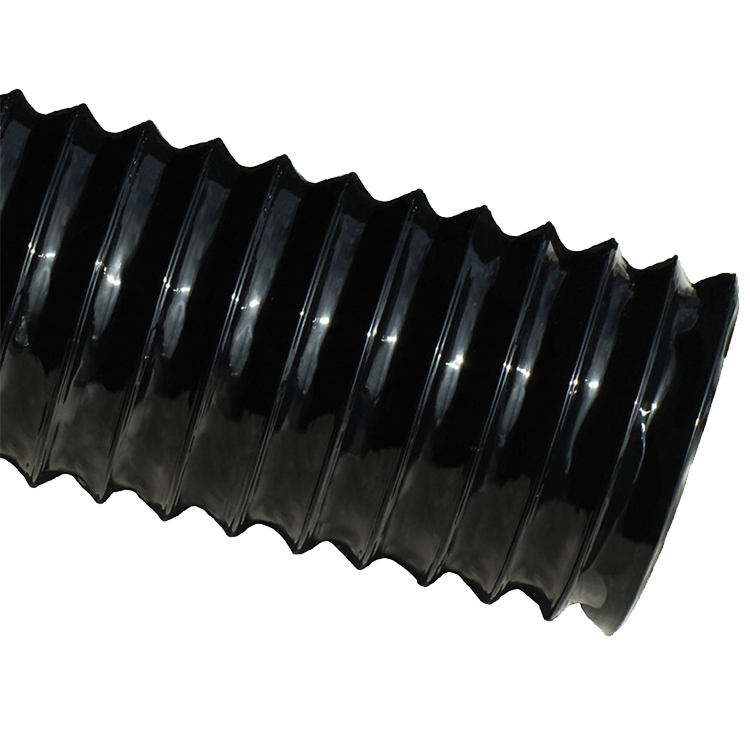

“Thermoplastic Flex Medium-Duty”

“Neoprene Flex Conductive”

“Urethane Flex Static Dissipative”

“Urethane Flex Self Extinguishing”

“PVC Flexduct Medium-Duty”

“Urethane Flex Extra Heavy-Duty”

“Thermoplastic Flex White”

“PVC Flexduct Heavy-Duty”

“PVC Flex Self Supporting”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex Heavy-Duty”

“Neoprene Flex – 2 ply Heavy-Duty”

“Neoprene Flex – 2 ply”

“PVC Flexduct Light-Duty Blue”

“Thermoplastic Flex Light-Duty”

“Thermoplastic Flex Extra Light-Duty”

“Neoprene Flex – 1 ply”

Screw Clamps

What Kind of Dust Do Factories Produce?

Industrial dust, otherwise known as ‘process dust,’ is the byproduct of manufacturing and processing manufactured materials. Process dust is not specific to one type of material; rather, it encompasses any dust that is the byproduct of processing raw materials into finished products. Processes such as cutting, sanding, drilling, crushing, and milling can produce large volumes of industrial dust, and depending on the type of dust and its application, it could be an extreme safety concern for the workers and the facility. From metal shavings to rubber dust and pellets, the particle composition varies widely from material to material. However, every kind of industrial dust contains metals and chemicals that can be harmful if inhaled. However, it is essential to note that several types of industrial dust are highly flammable, and if they come into contact with an ignition source, they can produce a devastating explosion. With these factors in mind, manufacturers and factory workers must uphold and follow every safety precaution and rule possible to prevent any industrial dust-related incident from occurring.

“Urethane Flex Heavy-Duty”

Is It Safe to Work in a Dusty Environment?

Generally, working in a dusty environment is never safe, and this is especially true for industrial factories and workshops. As industrial facilities incorporate different types of heavy-duty equipment and machinery to process raw materials into finished products, industrial dust is generated in large volumes and at a rapid rate. While inhaling everyday household dust can trigger symptoms such as asthma and allergies, industrial dust can be much more dangerous as it can create chronic respiratory problems and can lead to lung disease. While OSHA (Occupational Safety and Health Administration) does not have a particular standard on how industrial-grade dust is collected and removed, they do require industrial workshops to utilize a dust collection system with HEPA (High-Efficiency Particulate Air) filters to ensure factory workers that the air around them is safe to breathe once the dust has been collected. According to the EPA (Environmental Protection Agency), standard dust collection vacuum filters have a standard 99% efficiency rating for capturing and filtering out dust particles. However, HEPA filters have a 99.97% efficiency rating, and while .97% doesn’t seem like much, it makes all the difference because HEPA filters trap small harmful particles that are often missed by standard vacuum filters, and their presence can ultimately affect how much industrial dust is captured and filtered.

“Urethane Flex Extra Heavy-Duty”

- Ideal for severe service applications

- Clear is manufactured with FDA acceptable materials

The “Urethane Flex Extra Heavy-Duty” is a flexible heavy-duty hose as its name indicates! This is an ultra heavy-walled hose designed to work in abrasive material handling applications. Made from polyurethane hose materials, this product is the ideal flexible material handling hose when durability is a top priority. The polyurethane material gives this flexible material handling hose excellent tear and abrasion resistance while offering excellent flexibility. “Urethane Flex Extra Heavy-Duty” hoses made from polyurethane will often outwear other rubber, PVC or thermoplastic hoses where severe abrasion is a factor. Polyurethane has been proven to be vastly superior to rubber and plastics in terms of abrasion and tear resistance. Compared to plastics, urethanes offer superior impact resistance, while offering excellent wear properties and elastic memory. This product’s hose materials and construction make it an ideal choice for heavy-duty applications involving abrasives and large bulk materials.

The “Urethane Flex Extra Heavy-Duty” flexible material handling hose is designed to work around wide temperature ranges. This polyurethane hose works in temperatures ranging from -65 to +225 degrees Fahrenheit. Even when working in extremely low temperatures, this polyurethane hose maintains its excellent flexibility. In addition to working in wide temperature ranges, this product also features superior chemical resistance.

What Type of Dust Is Flammable?

According to OSHA, flammable dust is defined as any material that will burn in the air; more specifically, they classify it as any finely divided solid material that can present a fire or explosion hazard when dispersed and ignited. Industrial dust and debris such as wood, and plastic are naturally highly combustible and require factories and industrial workshops to take extra precautionary steps to assure the safety of the facility and its workers. Considering how combustible dust is composed of fine particles that can ignite rapidly when exposed to an ignition source, industrial facilities must eliminate as many ignition sources as possible to prevent a dust-related explosion. As a result, many dust collection systems utilize a static-dissipative flex hose to collect combustible dust securely without worrying if it will suddenly ignite. An anti-static flex duct is a type of flexible ducting specifically designed to reduce and discharge static buildup by allowing electrostatic energy to escape through the conductive hose wall. As electrostatic energy is generated by friction when combustible dust is collected, allowing this energy to discharge and escape will prevent a static charge from developing within the flexible duct and any possibility of igniting the accumulated dust. Beyond safety means, an anti-static flex hose is a practical option for a dust collection duct and is one of the best options for those looking for a safe, reliable, and flexible dust collection hose.

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Ideal for clean room and material plastic processing applications

- Surface resistance level: 108 – 1010 Ohms/Square

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Light-Duty Blue”

“PVC Flexduct Light-Duty Clear”

“PVC Flexduct General Purpose Clear”

How Do You Deal with Dust in a Factory?

The best and most efficient way to collect dust in an industrial setting is by utilizing dust collection systems and reliable flexible ducting. A dust collection system is a device used to improve air quality and sanitation in facilities and workshops that generate a substantial amount of dust. Dust collection systems can come in various styles, designs, and weight classes, but choosing one that can appropriately handle your specific application is important. While shop vacs are a popular and cost-effective means to collect dust and abrasive debris, their efficiency will vary depending on the type of dust collected. If the industrial dust is too abrasive, like metal dust, for example, shop vacs may be ineffective because the dust will cause significant wear and tear on the shop vac’s dust collection duct and internal systems. With that in mind, there are two types of dust collection systems specifically designed to collect industrial dust: Single-Stage and Double-Stage. Single-stage dust collectors draw dust into the unit using a spinning impeller, separating the air and dust through a filtration system and placing them into separate bags for disposal. Meanwhile, a Double-stage dust collector utilizes a ‘cyclone’ system that draws air into a separator where ultra-fine particles are captured, and the air is filtered and exhausted back into the room. By incorporating one of these dust collection systems into a factory or workshop, you can create a safe and healthy environment that prevents chronic dust-related illnesses from developing. No matter which type of dust collector is used to collect industrial dust, these collection systems must incorporate a durable dust collection pipe to withstand the daily rigors of industrial dust collection.

“PVC Flexduct Heavy-Duty”

- Good chemical & moisture resistance

- Excellent choice for ventilation applications, dust & fume removal

- Clear is manufactured with FDA acceptable materials

The “PVC Flexduct Heavy-Duty” is a heavyweight PVC wall hose reinforced with a spring steel wire helix offered in blue or clear. These flexible ducts are designed for light bulk material handling, heavy-duty ventilation applications, dust, and fume removal. This hose provides excellent internal and external abrasion resistance and is resistant to an array of chemicals and moisture. These heavy-duty hoses are great for applications where light materials will be handled and abrasion resistance is a must. Under normal conditions of use, the factor most strongly influencing the durability of PVC ductwork material is its resistance to oxidation by atmospheric oxygen. PVC (i.e., PVC Ductwork), having the molecular structure where the chlorine atom is bound to every other carbon chain, is highly resistant to oxidative reactions and maintains its performance over a long time.

The “PVC Flexduct Heavy-Duty” is a material handling hose product that is available in inside diameter sizes ranging from 1.25” up to 24” ID. This large range of ID sizes provides you with a heavy-duty hose that is great for a variety of applications, such as fume ventilation, dust collection, pharmaceuticals, and lawn and leaf collection. These heavy-duty hoses are available in blue and clear in standard 25-foot and 50-foot sections with plain cut ends.

“Urethane Flex Heavy-Duty”

“Urethane Flex Medium-Duty”

“Urethane Flex Self Extinguishing”

“Urethane Flex Light-Duty”

“Urethane Flex Extra Heavy-Duty”

What Kind of Flex Hose Should I Use for Industrial Dust Collection?

Due to the material’s build and composition, a polyurethane flex duct is among one of the best options for those looking for a flexible dust collection hose. Polyurethane as a material is one of the sturdiest elastomers that can last for years, even in the harshest and most demanding environments. Our “Urethane Flex” hoses are available in different styles and weights applications from light, medium, heavy, and extra heavy duty. However, it is essential to note that as the urethane hose wall gets thicker and heavier, the more the flex hose will lose in flexibility. Despite this drawback, a polyurethane flexible duct is at the top of its class and can cater to many applications across multiple sectors as it features high tensile strength and resistance to abrasive materials, chemicals, and extreme temperatures. As a dust collection hose, our polyurethane material handling flex duct is ideal for collecting industrial dust and debris, such as metal shavings, rubber debris, and plastic pellets. “Urethane Flex” hoses are also available in clear, black, and blue colored walls; however, the clear translucent color is especially useful for operators to detect obstructions and debris buildup in a dust collection hose. Another important factor that is essential to note for “Urethane Flex” hoses is that while they are more expensive than other flexible hoses, they consistently outperform flexible ducts, such as PVC and rubber hoses, regarding service life. Considering all of these features, if you are searching for a dust collector hose that can withstand the most grueling industrial applications, then a polyurethane flex hose will be the one to do so.

“Urethane Flex General Purpose Black”

- This hose is in stock in all ID sizes and in 12 and 25 foot lengths. Stocked items can ship in 24 hours of any order.

- Great compressibility

- Designed for wide temperature ranges

The “Urethane Flex (General Purpose) Black” is a reliable and cost-effective flexible duct for light-to-medium grade applications involving air, dust, and materials transfer. Made from durable polyurethane, it is a black colored hose that exhibits superior compressibility, flexibility and abrasion resistance. The body of this polyurethane ducting is reinforced by a spring steel wire helix that acts to give the hose a sturdy physical build while also helping to improve its compressibility at the same time. The superior flexibility of this hose allows it to be used effectively in situations where the hose has to be bent at tight angles in order to reach more isolated areas. Compressibility is also another key feature of this flexible material handling hose because it allows the end user to store and transport the flexible duct with ease.

Applications involving the transfer of materials, from light dust to larger solid wood chips, can wreak havoc on the walls of most plastic hoses. Polyurethane is the ideal plastic material for use as a flexible material handling hose. The key factor is that polyurethane possesses a high rate of resistance against physical wear. It exhibits a longer lifespan in physically demanding situations. As an added bonus, polyurethane brings a high level of resistance to solvents such as oils and grease.

“Thermoplastic Flex Extra Light-Duty”

“Thermoplastic Flex Light-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Thermoplastic Flex Medium-Duty”

What is Thermoplastic Rubber?

Thermoplastic rubber is a strong rubber-like elastic material used for a variety of products, such as flexible ducts and hoses. As a material, thermoplastic rubber is an inexpensive manufactured synthetic rubber possessing the best characteristics of rubber and plastic. Our “Thermoplastic Flex” ducts are an excellent all-purpose alternative for industrial ductwork and applications. These flexible ducts have a successful track record in a wide range of material handling applications such as collecting metal shavings, wood dust, and transferring abrasive materials, and as a result, these hoses serve as an outstanding option for your dust collection ductwork. These rubber hoses exhibit superb durability against extreme temperatures and especially against abrasive materials, which makes them great for industrial workshops and facilities that require flexible ducts that can withstand demanding environments. The thermoplastic flex duct comes in different styles, weight classes, inside diameter (I.D.) sizes, lengths, and functionalities, which gives operators a range of options to choose from and find the perfect duct to cater to their application. Similarly to the “Urethane Flex” Hoses, our “Thermoplastic Flex” ducts will become less flexible as the wall thickness increases. While sturdy flexible hoses such as polyurethane are ideal for most industrial applications, our “Thermoplastic Flex” ducts are a cost-effective alternative for those searching for industrial-grade quality at a reasonable price.

“Thermoplastic Flex Heavy-Duty”

- Suitable for more demanding positive and negative pressure applications

- Great moisture and UV resistance

The “Thermoplastic Flex Heavy-Duty” is a heavy duty rubber hose that is designed to withstand positive and negative pressure applications. This heavy-duty hose is made from thermoplastic rubber, which offers great chemical resistance and fares better than standard rubber in extreme hot and cold environments. The thermoplastic composition of this heavy-duty hose also serves to provide excellent moisture, UV, and chemical resistance. Thermoplastic rubbers are a class of copolymers that possess both thermoplastic and elastomeric properties, generally made from a mix of plastic and rubber. They deliver enhanced performance and the potential for reduced system costs, compared to materials such as thermoset rubber. Thermoplastic rubber materials are also recyclable and exhibit outstanding chemical resistance.

This thermoplastic hose is reinforced with a spring steel wire helix, which protects the hose from wear and damage. The thicker wall of this hose makes it ideal for heavy-duty industrial uses, such as the movement of abrasives. Unlike other flexible hoses, the “Thermoplastic Flex Heavy-Duty” rubber hose is also able operate at both high and low temperatures. This high temperature hose features a temperature range of -40 degrees to +275 degrees Fahrenheit, making it the ideal choice for environments with wide temperature ranges. The thermoplastic rubber on this chemical resistant hose is also resistant to large amounts of moisture, UV, and ozone, which make this heavy-duty rubber hose the superior choice for outdoor environments.

“Neoprene Flex – 2 Ply”

Is Neoprene Sturdy Enough as a Dust Collector Hose?

Neoprene is a synthetic rubber that was designed to be a more robust alternative to rubber hoses. While the material is one of the more expensive options, “Neoprene Flex” hoses offer industrial factories a tensile option that can withstand the daily rigors of industrial-grade dust collectors. Featuring a strong resistance against abrasive debris, chemicals, and extreme temperatures, “Neoprene Flex” hoses are incredibly effective at material handling applications and come in different wall thicknesses and functionalities such as static dissipation. The material also features unique designs such as flame retardancy and degradation resistance to cater to industrial workshops looking for specific reliable ductwork. Depending on your product choice, you can even order custom inside diameter (I.D.) sizes that can go up to 60 inches, and order end finishes with cuffs. One of the most striking features of the “Neoprene Flex” hoses is their overall flexibility, which is ideal for dust collection ductwork because it allows operators to collect industrial dust in hard-to-reach places. While other materials such as thermoplastic, polyurethane, and PVC offer impressive flexibility, they are limited to the material’s composition and the hose’s design. As a result, the “Neoprene Flex” hose is one of the most flexible ducts that does not sacrifice flexibility with durability.

“Neoprene Flex – 2 Ply HD Heavy-Duty”

- Handles both positive and negative pressure

- Available with an external wearstrip

The “Neoprene Flex – 2 ply HD” is a heavy-duty hose recommended for light bulk material handling applications. Each flexible duct is made from double-ply neoprene coated polyester fabric, making for a thick walled hose that offers excellent flexibility. The material handling hose is then reinforced with a spring steel wire helix. This flexible hoses spiral design is made to withstand abrasive dust and other harsh materials. The neoprene and polyester construction of the “Neoprene Flex – 2 ply HD” offers superior abrasion resistance and excellent flex life. Neoprene resists degradation more than natural or other synthetic rubbers. This relative inertness makes it well suited for demanding applications.

The material transfer ducts have a high strength to weight ratio that is augmented by excellent flow characteristics. The “Neoprene Flex – 2 ply HD” material handling hose can handle both positive and negative pressure and has a working temperature range from -40 to +250 degrees Fahrenheit. This hose can be ordered with an external wear-strip in cases where abrasion on the exterior of the hose is possible. Also, an additional neoprene coating can be added for better abrasion and chemical resistance. The additional coating and added wear-strip can extend the life of this material handling hose in demanding environments.

“PVC Flex Self Supporting”

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Light-Duty Blue”

“PVC Flexduct Heavy-Duty”

PVC Flex Ducts- A Cost-Effective Alternative

“PVC Flex Ducts” are one of the most affordable and readily available ducting options that suit various applications. Polyvinyl chloride (PVC) is one of the world’s most widely produced plastic polymers due to its versatility and wide range of industrial applications. As a result of PVC’s versatility, it stands as a tremendous, cost-effective general-purpose ducting option for industrial-grade dust collection. Coming in different inside diameter (I.D.) sizes, designs, functionalities, and even weight classes, “PVC Flex Ducts” offer the most variety for your dust collection system and can cater to your applications and specific machine requirements. Depending on your product choice, “PVC Flex Ducts” are also compressible, making them easy to transport and store. While PVC “Flex Ducts” are not as durable as other materials such as neoprene, polyurethane, and thermoplastic, they are an affordable, adaptable, and dependable flexible dust collection hose for any industrial-grade dust collector ductwork.

“PVC Flexduct Light-Duty Clear”

“Smooth-Tube PVC”

- Completely smooth interior prevents clogs and maximizes airflow

- Cost-effective smooth interior hose

- External helix acts as wearstrip, protecting the outside of the hose

- Available in flame retardant version

The most distinguishing feature of these PVC hoses is their smooth interiors. It is, after all, where they get their name. If you take a look inside these flexible air ducts, you will notice that they do not have ridges, curves, or any kind of design on the inside. The purpose behind the smooth interiors is to prevent any small particles from getting stuck inside the hose. That way you will not have to worry about dealing with clogs. It ensures that the flex ducting benefits from a maximized level of airflow.

This clear flexible hose is a longer lasting hose because it is crush and abrasion resistant. This is thanks to the strong PVC outer helix that goes along the body of these flexible air ducts. This outer wearstrip provides the hose with a more solid frame. It is ultimately more durable than competing hoses that lack the external wearstrip. It can resist abrasions from rocks and other small physical objects in case it is dragged along a rough and abrasive surface. The wonderful thing about this flex ducting is that despite its superior durability, it is also very flexible. It can be flexed and bent to suit your application as needed. One of the benefits of these flexible air ducts is that it is available in a flame retardant version. It can also handle hot temperatures up to 160° F.

Smooth-Tube Hoses

When it comes to collecting industrial-grade dust, you require a flexible hose that can withstand all of the abrasive debris being transferred. The “Smooth-Tube” series is one of the most practical flexible hoses that one can use for material collection and handling. Featuring a completely smooth interior and a durable abrasive-resistant wall, a “Smooth-Tube” flex hose can withstand crushes, impacts, and punctures, making it ideal as industrial dust collection piping. However, the main feature of this smooth interior flex hose is its translucent design that allows operators to spot any blockage that occurs. By being able to detect blockages in a flexible hose, it will enable operators to clear debris and significantly minimize maintenance downtime effectively. In addition, the hose features a smooth interior, making it less likely for debris to get stuck inside, and maximizes the airflow as dust and debris are transferred from one point of the hose to the other. The “Smooth-Tube” series is available in various material options, such as standard PVC, thermoplastic rubber, and even polyurethane film, making this flexible hose one of the most diverse.