“Air Ventilator Black”

“PVC Flexduct General Purpose Clear”

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Clear”

“Wind Handler WS”

“Wind Handler Insulated TU”

“Wind Handler”

“Tornado Flex Insulated AD”

“Tornado Flex In Sack”

“Tornado Flex”

Screw Clamps

What Is an Air Duct In HVAC?

An HVAC air duct is a component that distributes heat or cool air to each room throughout a building. These air ducts are connected to an HVAC system that filters and generates temperature-controlled air before transferring throughout a building’s ductwork. The term HVAC stands for Heating, Ventilation, and Air Conditioning, and it refers to the systems that regulate and control indoor air quality and temperature. Since its creation in 1902 by Willis Haviland Carrier, the HVAC system has gone through numerous iterations until it became an essential part of residential structures, commercial buildings, and medium to large factories in the United States. Fast-forward to today, HVAC systems and their ductwork are invaluable means of personal climate control and indoor ventilation.

“HVAC Insulated-Flex”

What Is the Difference Between AC and HVAC?

An air conditioner is designed to lower a room’s temperature by generating cool air and transferring it throughout a building’s ductwork. On the other hand, HVAC is a system designed to cool, heat, or ventilate air flow throughout a building, giving people control to manage climate, airflow, and overall air quality. The main difference between an AC and an HVAC system is its standard functions. According to the Department of Energy, air conditioners in residential homes use about 6% of all the produced electricity in the United States, making up for both permanent and portable installations. While the energy usage of permanent and portable AC units can depend on how effective the ducting and application are, the energy usage for HVAC systems in the United States is estimated to be around 12% of all the produced energy due to their multifunctional design. Despite the increased energy usage, HVAC systems are a popular option for personal climate control and ventilation for their range, adaptability, and overall reliability. While HVAC can generate higher energy and utility costs, it can be reduced if proper and effective HVAC systems and ducting are applied.

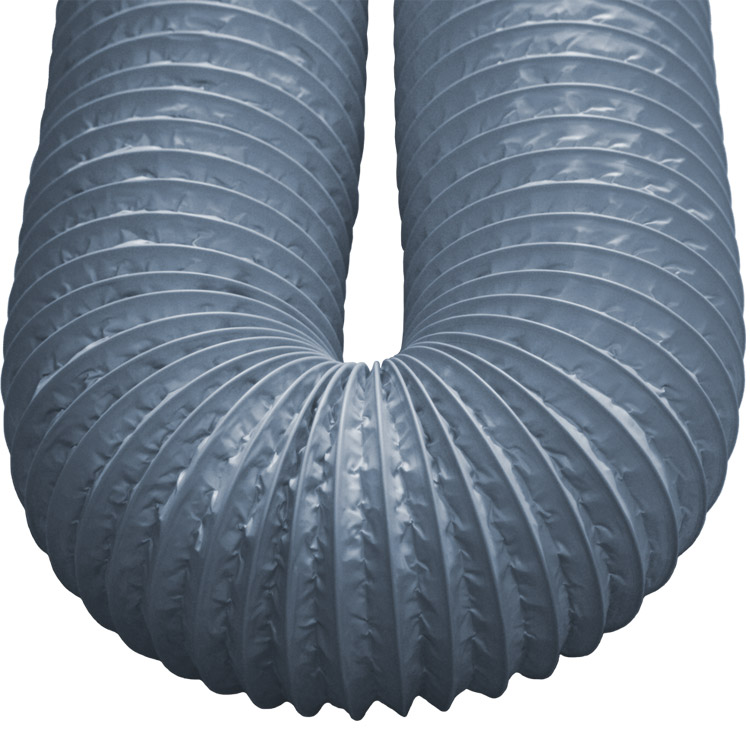

“HVAC Ventilation-Flex”

- Ultra affordable flexible duct

- Alum 0.0065 mm in thickness

- PET 0.014 mm in thickness

- Gray PVC 0.010 mm in thickness

The HVAC Ventilation Flex is a high-quality and affordable ducting hose which provides an excellent option for customers looking for air movement solutions. These durable HVAC ducts are designed specifically for the transfer of air, and they excel in applications including air conditioning duct work. The HVAC Ventilation Flex is a versatile and flexible HVAC duct which can be used in a range of different settings, from residential use to industrial applications.

With its dual layer PVC and aluminum body, the HVAC Ventilation Flex has a great range of features. To start with, it provides a high level of noise and heat insulation. This insulation allows the hose to remain effective in extreme hot and cold temperatures, with a working range from -20 degrees to 160 degrees Fahrenheit. This means that the ducting can support the movement of air within that temperature range. This makes it effective as an air conditioning duct or a hot air vent, among other applications. The body of this ducting hose is also extremely flexible, allowing it to be contorted and manipulated into various shapes and tight spaces as required by a project or application.

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Blue”

What Are the Four Main Types of HVAC Systems?

There are four main types of HVAC systems: Split, Hybrid, Duct-free, and Packaged Heating and Air. Split Systems are the most common type of HVAC system, and as the name would imply, this HVAC system splits up the two central units: the heating unit placed inside a home and the cooling unit placed right outside. Despite being set in two separate locations, the split system connects the two through a refrigeration line and can send temperature-controlled air throughout a building’s ducting. The split system is the most widely used model in the United States due to its general design, application, and reliability in sending climate-controlled air through air conditioner ducts.

The Hybrid System, also known as a Dual Fuel Heat Pump, is an HVAC system that combines a traditional gas furnace with an electric heat pump. What makes the hybrid system particularly stand out is its ability to automatically alternate between the gas furnace and electric heat pump depending on the season, temperature, and the needed function. This function makes it ideal for residential and commercial units in mild climates with fluctuating temperatures. While the hybrid system utilizes and shares a lot of similar functions to the split system, such as its usage of traditional ducts and thermostats, the hybrid system is a more cost-effective and energy-efficient option for those looking for an environmentally friendly alternative in their HVAC systems.

A Duct-free HVAC System, more commonly known as a mini-split system, is a type of HVAC that does not require extensive ductwork that is usually seen in traditional central air systems. The duct-free HVAC system incorporates multiple wall-mounted blowers, and each blower is built to provide temperature controlled air to a single room or area. While the duct-free HVAC system is not intended to control indoor climate throughout multiple rooms, they are great for smaller residential units, hotel rooms, and newly refurbished areas that are not serviced by ductwork. Depending on your application, the duct-free HVAC system can be a cost-effective means to lower energy usage and waste.

The Packaged Heating and Air System is a type of HVAC system commonly found in attics and crawlspaces. As the name implies, it contains all the necessary components for heating and cooling, all packaged within a single compact unit. It is a space-saving solution for residential and commercial units with limited square footage and overall space. While this type of HVAC system is less powerful and durable than others, standard maintenance is relatively affordable and accessible due to its compact, all-in-one design.

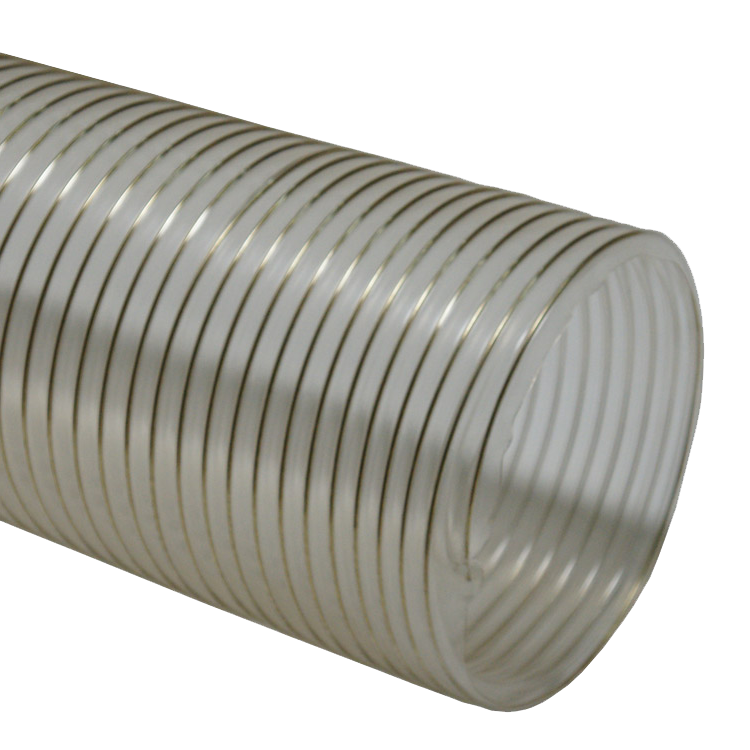

“PVC Flexduct General Purpose Clear”

- Great flexibility with tight bending characteristics

- Good chemical and moisture resistance

- Excellent compressibility

- Excellent choice for ventilation applications, dust & fume removal

The “PVC Flexduct General Purpose Clear” is a cost-effective PVC hose suitable for a wide range of light to medium duty air, dust, and fume related applications. The body of this clear flexible hose is made from PVC material and is reinforced by a steel wire helix. The clear PVC material provides these air and dust collection hoses a moderate degree of chemical and moisture resistance.

This PVC ducting is very flexible. It has a high bend radius that will allow you to carry out your air/dust collection application in the most difficult to reach areas. Since it is a highly compressible PVC hose, it is ideal for easy storage and can be moved from one job to the next. One of the biggest benefits of having a clear flexible hose such as this is due to the fact that you can keep an eye on what is going through the hose itself. You can easily spot any clogs or blockages that may occur within these dust collection hoses, allowing you to identify and fix the problem. Another great advantage this PVC hose has over other similar competing products is its cost-effective pricing.

“Aluminum Flex 400”

What Are the Five Types Of Ducting In HVAC?

There are five types of HVAC ducting: Rigid, Semi-Rigid, Flexible, Insulated, and Non-insulated. Rigid ducting is a type of ductwork characterized by its solid, non-flexible construction and is often used as a permanent ducting solution for many HVAC systems. Rigid ductwork is made from metals such as stainless and galvanized steel, making it highly durable and perfect for commercial and industrial applications. Despite its place in commercial and industrial settings, rigid ducting can also used in residential applications, especially in areas where the ductwork might be exposed to physical or environmental stress. As a result, rigid ducting is considered the go-to HVAC duct for its durability and lifetime value.

Semi-rigid ducting is a type of ductwork that offers both flexibility and durability and serves as a middle ground between rigid and flexible ducting. Usually made from lightweight materials such as aluminum, the construction of semi-rigid ducting allows it to be bent around obstacles while maintaining its shape, making it an excellent option for buildings that require ductwork in hard-to-reach places. Semi-rigid ducting is also much easier to install than rigid ducting due to its lightweight design. Outside of residential applications, semi-rigid ducting can be used for commercial applications such as exhaust ventilation and range hood ventilation. As such, semi-rigid ducting is a versatile flexible HVAC duct for systems and buildings that need a balance of flexibility and durability.

A great semi-permanent option for all your ventilation and ducting needs, a flexible duct is known for its adaptability and easy-to-install nature. Flexible ducts are made from various materials and are designed to withstand extreme temperatures. Depending on the type of product you purchase, it can resist multiple external factors such as abrasive materials, chemicals, corrosive fumes, moisture, UV rays, and solvents. Additionally, they are particularly useful for facilities that cannot install rigid ducting due to architectural constraints. As a result, a flexible hose is widely used in residential and commercial buildings and is a popular option for HVAC systems.

One of the best HVAC ducting types, insulated ducting, is ductwork with a layer of insulation as part of its initial construction. The primary purpose of insulated ductwork is to maintain the temperature of the air and minimize any temperature loss as it is being transferred from one point to another. Insulated ducts ensure that your HVAC system doesn’t need to overexert itself to compensate for heat loss. With that in mind, the effectiveness of insulated ductwork will largely depend on the type of insulation and its thickness. However, it is essential to note that insulated ductwork can be applied to other HVAC duct types, such as rigid, semi-rigid, and flexible, making it one of the most readily available HVAC duct types. So, if you are looking for an HVAC air duct that will significantly improve energy efficiency and lower overall energy waste and utility costs, an insulated HVAC duct will be one of the best options.

Non-insulated ducts are an affordable HVAC duct type with no insulation material attached to initial construction. Similarly, to insulated ducts, non-insulated ducts are available for other HVAC duct types, such as rigid, semi-rigid, and flexible. While the choice of material and design is often dependent on the specific application and requirements of the HVAC system, it is essential to note that using a non-insulated air duct for your HVAC system will likely cause temperature loss. Temperature loss refers to the reduced temperature of heated air as it is being moved throughout the HVAC air ducts. Without insulation to slow down the process as it is being transferred, residential units and commercial properties will experience higher energy and utility costs due to temperature loss. While non-insulated ducting is an affordable alternative, it will surely generate costs in the future.

“HVAC Ventilation-Flex”

“Aluminum Flex 280 – Compressible”

- Designed for extreme temperature applications

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The Aluminum Flex 280 – Compressible comes prefabricated in a variety of different inside diameter (I.D.) sizes: 3″, 4″, 5″, 6″, 8″, 10″, and 12″. The walls of this flexible metal tubing are 0.1 to 0.11 mm. thick, and it has an I.D. tolerance of 0 to 0.1 inch. Its end finishes are plain cut, and it comes in a classic, metallic-silver colorway. This flexible metal hose is also semi-rigid, which means that, once you bend it into a certain position, it will stay that way without any added support. Of course, you can bend it again to reform the duct into a different position. In sum, it’s likely that you will not need to use any accessories such as elbows to fit your Aluminum Flex 280 – Compressible into looping or bent positions.

This flexible metal duct is designed with air and fume ventilation applications in mind, thus making it well-suited for a variety of residential, commercial, and industrial applications—especially those that intend to transport high-temperature matter. Wood stoves, for instance, need to properly ventilate hot smoke from the wood they burn. The Aluminum Flex 280 – Compressible is a natural fit for these kinds of applications—especially since, oftentimes, a wood stove’s exhaust duct must navigate a circuitous pathway to reach the destination where it expels the stove’s fumes. Other common uses for this metal flex-duct include chemical fume ventilation, circuit board cooling, and air conditioner ducting, among other things.

“Tornado Flex Insulated AD”

Is Flex Duct Better Than Hard Duct?

Flexible ducts are a much better alternative than hard ducts for HVAC systems. The main differences between flexible and hard ducts are their durability, installation, and construction of materials. Hard rigid ducts are a durable permanent solution for all of your HVAC ducting needs, but due to their size and overall weight, it has a meticulous installation process with generally high costs. Compared to a flexible HVAC duct, on the other hand, they are a lightweight, cost-effective, and easy-to-install alternative that can be installed anywhere. Depending on your product choice, flexible hoses can also withstand extreme temperature ranges for long periods, making them ideal for any general HVAC application. However, it is important to note that flex hoses are less durable than hard ducts, and depending on your choice of product, it may be subject to occasion blockage, so there needs to be routine maintenance for repairs and cleaning. Despite some regular upkeep, flex hoses still serve as a tremendous semi-permanent alternative to hard, rigid ductwork for any of your HVAC ducting needs.

“Air Ventilator Yellow”

- Lightweight duct hose

- Very cost effective

The “Air Ventilator Yellow” flexible ducting hose can be useful in many industrial air movement applications. These lightweight hoses are made from PVC vinyl coated polyester fabric and has been reinforced with a spring steel wire helix for added strength when flexed. Each section of yellow flex duct is constructed with a protective external wear-strip. The protective wear-strip provides an added layer of protection from dragging and scraping the hose material on the ground. All hose ends feature belted cuffed end for easy installation. This allows for quick and simple use without the need for clamps.

This PVC flexible ducting hose is lightweight and cost effective. The Air Ventilator hoses are our least expensive hose products and are priced at a fraction of most hoses in their class. All hose material in the “Air Ventilator Yellow” flex duct has a temperature range of-20 to +180 degrees Fahrenheit for industrial air movement. Each section of the hose material is highly compressible and standard lengths are 25 feet. The flex duct can easily retract so it can be compressed from its full length down to just three feet. This makes transportation and storage convenient, especially when the hose is used for seasonal applications. These lightweight hoses are available in several different sizes, including 4, 6, 8, 10, 12, 16, 18, 20, and 24 inch. This flex duct is generally inventoried in the aforementioned sizes and will ship within 24 hours of an order. In addition, all sizes of the “Air Ventilator Yellow” can ship via FedEx Ground, making for a less expensive fulfillment option.

“Air Ventilator Orange”

“Air Ventilator Black”

What Is the Best Ductwork for HVAC?

Insulated ducts are the best and most efficient type of duct to use for your HVAC system. As HVAC systems are mainly designed to generate cool and heated air throughout a building’s ductwork, insulated ducts are perfectly designed to transfer temperature-controlled air to their intended destinations. While non-insulated ducting may seem like an affordable alternative, it will generate higher costs in the long term due to heat loss. Approximately, non-insulated ducts can lose up to 40% of generated heating and ultimately cause HVAC systems to operate 50% harder to make up for the loss and raise energy and utility costs. This is why insulated ducting is the best choice for HVAC ductwork because insulated ducts feature insulation materials that slow down conductive and convective heat flow and ensure that heat is not lost through the ductwork. While many different types of products are available for HVAC ducting, the best way to determine which insulated ductwork you need is by determining the ductwork’s R-value. The R-value is a unit of measurement that helps determine an insulated product’s ability to resist heat flow. The higher the ductwork’s R-value, the more likely it will significantly reduce heat loss through your HVAC air ducts. So, if your insulated ducts have a low R-value due to their initial design, then a straightforward way to increase their R-value is by layering the ducts with additional insulation. While this can ultimately increase the overall weight, recent advancements have made these materials and products lighter, more effective, and, as a result, easier to install.

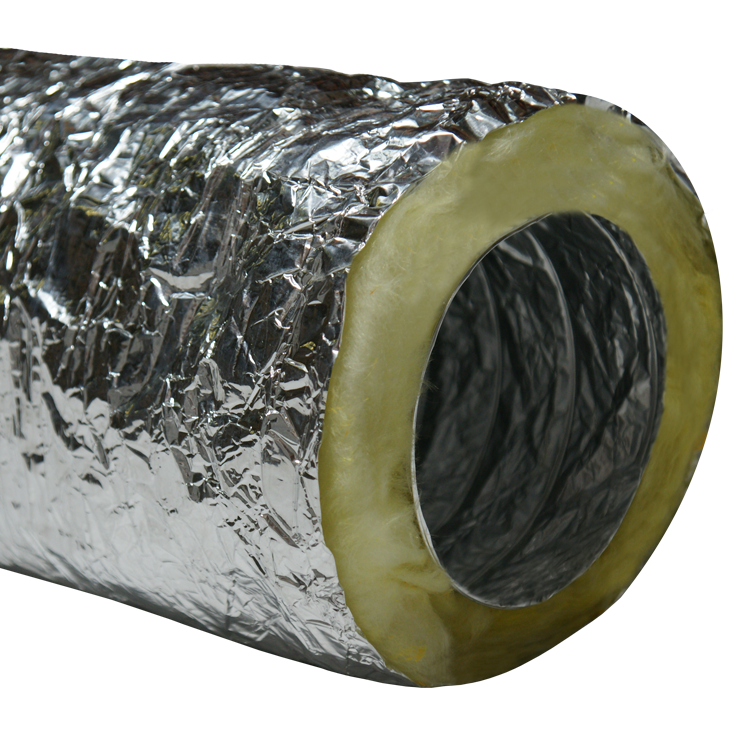

“HVAC Insulated-Flex”

- Insulation maintains temperature of air inside hose

- Provides acoustical as well as thermal insulation

The “HVAC Insulated-Flex” hose is a superb choice for HVAC air duct use. These ducts for air conditioning applications are double-ply insulated flexible hoses that are made of aluminum foil and PET film layers. Each HVAC flexible duct is insulated with glass wool material. This product is beneficial to consumers because of its affordable price point. It is definitely a more cost-effective HVAC ducting option than other competing hoses. It will also look good in any setting that it is placed in thanks to the shiny silver insulation material on the outside of the hose.

The insulated nature of this portable air conditioner hose allows it to operate in both high and low temperatures. The double-ply insulated material of this HVAC air duct allows it to function well in temperature ranges between -20° F and 160° F. Whether your application involves the transfer of cold air or hot air, these HVAC ducts for air conditioning uses can maintain their structural integrity with ease. The insulated material also helps maintain the temperature of the air that is present inside the hose.

A key advantage of this HVAC flexible duct is how easy it is to handle. This is a portable air conditioner hose that can be easily compressed for transportation purposes. This is a great HVAC ducting hose to have if your applications are constantly on the move.

“PVC Flexduct General Purpose Clear”

“PVC Flexduct General Purpose Blue”

What Is the Best Material for HVAC Ducting?

Insulated hoses are regarded as the best material for general HVAC ducting, however, if your application requires a different type of material, there is plenty of ducts made out of different materials that suit your specific needs. Aluminum Flex hoses, for example, are a great lightweight option that can withstand extreme temperatures and resist corrosive fumes, chemicals, and general metal fatigue. While Aluminum Flex hoses are geared towards industrial air and fume ventilation, they are a great cost-effective material for general residential HVAC ducting. If you want something that offers more options for HVAC ducting, PVC is a great, cost-effective material for your HVAC systems. Whether you opt for PVC-Vinyl Coated Air Ventilators or PVC Flex Ducts, PVC is a strong, durable, lightweight material that is great for air and fume ventilation. Depending on your product choice, they can be resistant to a range of factors. For example, PVC- Vinyl Coated Air Ventilators are resistant to abrasive materials; meanwhile, PVC Flex Ducts are also designed to resist chemicals and moisture. Whichever product you go with, PVC is a great, cost-effective option known for withstanding a range of extreme temperatures, making it great for residential, commercial, and industrial applications. However, if you are looking for a highly durable material that is designed for large air volumes and can be customized, then polyester fabric duct hoses such as Tornado-Flex hoses and Wind Handlers are great viable options. Polyester fabrics are popular and widely used for their durability, resistance, and customization potential. So products such as Wind Handlers are not only naturally designed to withstand extreme temperatures, but they are also coated with neoprene, which is produced by the polymerization of chloroprene. As a result, neoprene-coated hoses exhibit durability and resistance against abrasion and chemicals, making them one of the sturdiest materials to use for HVAC ducting.

“PVC Flexduct Light-Duty Clear”

- Great flexibility with tight bending characteristics

- Good chemical and moisture resistance

The “PVC Flexduct Light-Duty Clear” is a medium-weight clear PVC wall duct hose reinforced with a spring steel wire helix for industrial air movement and fume control applications. These commercial hoses provide great flexibility with tight bending characteristics and offer good chemical and moisture resistance. This duct hose is great for applications where ventilation and flexibility are a must. PVC hose material is an amorphous polymer, which results in a transparent finish. PVC hose material is non-transparent when they are manufactured using compounding agents. Since the main chain of the polymer is made by single bonds of carbon atoms, PVC has excellent chemical resistance.

The “PVC Flexduct Light-Duty Clear” light-duty duct hose has a working temperature range from -20 to 160+ degrees Fahrenheit. These commercial hoses are manufactured with FDA acceptable materials that can be used in food processing, pharmaceutical, and health care applications. PVC has polar groups (chlorine) and is amorphous, therefore it mixes well with various other substances. This makes for a chemically stable flex duct. This duct hose exhibits excellent flexibility and compressibility. In larger ID sizes, it has up to a 6 to 1 compression ratio, meaning a 12 foot length can compress down to 2 feet. In addition, the smaller sizes of this hose (2.25” and below) can handle a full vacuum at 29 Inch/Hg. Please refer to the product specification guide for exact information regarding the ID size you are considering.

“Wind Handler Insulated TU”

“Wind Handler WS”

“Wind Handler”

Can You Use Flex Hose for HVAC?

Ultimately, Flex hoses are the best ductwork option for HVAC systems because of their durability, adaptability, and wide range of practical and specialized applications. While there are many different types of flex hoses for your HVAC system, it is best to use an insulated air duct for your HVAC system because it retains heated and cool air for long periods. As HVAC systems consistently generate heated and cool air throughout a building’s ductwork, it is vital to have an insulated HVAC air duct that will perform up to your system’s operational standard. As a result, using an insulated HVAC air duct significantly improves energy efficiency and lowers overall energy and utility costs. Regardless of what kind of HVAC air duct you choose for your residential, commercial, or industrial application, it is critical to incorporate the best type that matches your usage.

“Wind Handler WS”

- Wearstrip offers additional external and drag resistance

- Great compressibility

The “Wind Handler WS” flexible hose is a single-ply neoprene coated polyester fabric hose with a wear-strip designed for air applications. Neoprene is a synthetic rubber that is produced by the polymerization of chloroprene and exhibits good chemical stability and flexibility over a wide temperature range. The duct materials used in this product are highly compressible and retractable. The compressibility of this ventilation ducting allows a 25 ft length of hose to be compressed down to just over 2 feet! This is especially useful when the air duct needs to be transported to a different location.

This product is unique because it features a wear-strip that provides external protection against abrasion and wear. The duct materials used in its construction make this hose ideal for moving large volumes of air in both portable and permanent ventilation systems. This flex hose is easy to handle and has the ability to bend and flex around small spaces and corners. The “Wind Handler WS” flexible hose is listed as UL 94 V-0 flame retardant. Being constructed of UL 94 V-0 listed duct materials means that the product will stop burning after being exposed to a flame within 10 seconds (given the source of fuel has been removed). This makes the hose ideal for applications where safety is a concern. This product has a working temperature range of -65 F to +250 F, allowing it to be used for a wide variety of applications.