“Wind Handler Insulated TU”

“Tornado Flex Insulated AD”

Screw Clamps

What Are Insulated Ducts?

Insulated ducts are a type of ductwork designed to maintain temperature-controlled air as it is being transferred from a generated source to its intended destination. Generally, insulation is made from cellulose, fiberglass, and mineral wool, and all of these materials are produced from recycled waste materials to conserve energy and create an efficient use for recycled materials. Insulation has come a long way since its origins in ancient Egypt, where the only means to maintain climate-controlled air was to construct buildings made entirely of thick mudstones. Fast forward to the 1950s, and insulation became popularized when fire retardant insulation was introduced, making homes more comfortable and safer. Insulated ducting is not only a smart way to save money, but it will help your heating and cooling systems run more efficiently. By strategically incorporating an insulated duct into your building, you can optimize how climate-controlled air is transferred and prevent costly, inconvenient daily occurrences such as temperature loss, noisy ducting, or a combination of both. Whether or not you use insulated flex ducts for residential HVAC systems, insulated ductwork is an energy-efficient means that can lower overall energy waste and utility costs and create a comfortable, livable environment.

“HVAC Insulated-Flex”

-

- Ideal for use for permanent and mobile air condition units

- Compressible and easy to transport

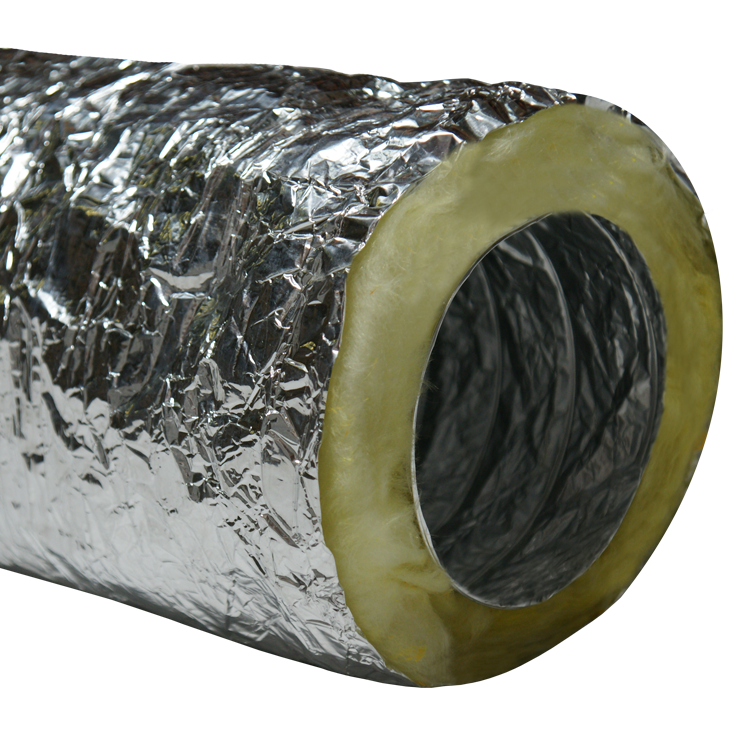

The “HVAC Insulated-Flex” hose is a superb choice for HVAC air duct use. These ducts for air conditioning applications are double-ply insulated flexible hoses that are made of aluminum foil and PET film layers. Each HVAC flexible duct is insulated with glass wool material. This product is beneficial to consumers because of its affordable price point. It is definitely a more cost-effective HVAC ducting option than other competing hoses. It will also look good in any setting that it is placed in thanks to the shiny silver insulation material on the outside of the hose.

The insulated nature of this portable air conditioner hose allows it to operate in both high and low temperatures. The double-ply insulated material of this HVAC air duct allows it to function well in temperature ranges between -20° F and 160° F. Whether your application involves the transfer of cold air or hot air, these HVAC ducts for air conditioning uses can maintain their structural integrity with ease. The insulated material also helps maintain the temperature of the air that is present inside the hose.

A key advantage of this HVAC flexible duct is how easy it is to handle. This is a portable air conditioner hose that can be easily compressed for transportation purposes. This is a great HVAC ducting hose to have if your applications are constantly on the move.

Should I Use Insulated Ducting?

Utilizing an insulated hose in your HVAC system is always a wise decision to ensure the heated or cooled air being moved from your HVAC unit to its delivery point maintains its temperature. Homeowners and real estate investors should use flexible duct insulation in places where they plan on inhabiting for extended periods because the amount of money saved in the long term. For instance, replacing an old, non-insulated hose that provides climate-controlled air to isolated areas such as basements and attics would save on energy bills. This is because many older homes utilized these spaces purely for storage purposes and did not consider the possibility of converting them to another potential room to live in. Most modern real estate investors are seeking to fully utilize every square inch of their properties because added spaces mean the added need for conditioned air. For real estate investors and property owners, using an insulated hose can help save them a myriad of maintenance costs and help increase the overall value of their investment. Since insulated ducts are no longer priced as a luxury good, they should be used in every instance. Additionally, insulated ducts are an excellent upgrade for those looking to replace their old and deteriorating flexible ducting with something new, sturdy, and multifunctional.

“Air Ventilator Insulated”

“Aluminum Connectors”

“Air Ventilator Insulated”

- Ideal for use for permanent and mobile air condition units

- Compressible and easy to transport

- Insulation maintains temperature of air inside hose

The “Air Ventilator Insulated” ventilation ducts are made from two single-ply PVC fabric layers, plus one layer of PET film with a cotton barrier meant for insulation. The insulated barrier in this flexible ventilation ducting hose makes it ideal of air movement applications. It is compressible and can be easily moved around, thus making it good for either permanent or temporary air conditioning uses. Primarily meant for residential or commercial level of air ducting and ventilation, it has a shiny metallic silver appearance that allows it to bring a sleek and professional look to the job.

The PVC fabric layers that make these vent hoses are very crucial to what makes them great ducting products. The PVC material provides these ventilation ducts with a superior level of resistance against moisture, ozone, and UV rays. As a result, they can be used in both indoor and outdoor applications. PVC material itself is resistant to various types of oils and alcohols, but it is best to not put this air hose in contact with more caustic chemical materials.

These insulated ducting and ventilation hoses should be used in residential and commercial applications. Use this ventilation ducts for AC ventilation, cold air supply, utility blowers, HVAC purposes, general-purpose residential ducting, and humidity control applications.

Is Insulating Ductwork Worth It?

Insulated ductwork is definitely a worthy installation and investment that can increase the overall value of your real estate. Many property owners who purchase a home with non-insulated hoses might resort to quick temporary fixes to insulate the property’s ducting, such as adding layers of insulation on top of the existing ductwork. While this technique can save time for those looking for a quick fix to their HVAC ducting needs, it is only a temporary solution to something that needs immediate attention. It is a popular misconception that installing new insulation onto an existing non-insulated flex hose is a cost-effective choice due to the low cost of the material and labor. However, this is a much more expensive option because non-insulated ducts are more expensive to insulate than new insulated ducts are for purchase. As non-insulated flexible hoses do not contain any features needed for an efficient HVAC system, it is far more affordable to buy a new insulated HVAC duct and replace it with the existing non-insulated one. Depending on the state of the existing ducts, trying to repurpose existing ductwork may cause more problems in the near future, such as discovering irreparable wear and tear and new rips and cracks forming. By purchasing a new insulated HVAC duct, property owners are investing in a new flexible hose that is better suited for HVAC systems, and depending on their product choice, it may even feature unique designs and attributes that can increase the overall performance of your HVAC systems.

“Tornado Flex Insulated AD”

“Wind Handler Insulated TU”

- Good for air handling applications.

- High tensile strength

- Compressibility allows for convenient storage

The “Wind Handler Insulated TU” duct materials allow this insulated duct to operate at both high and low temperatures. This polyester fabric hose has a temperature range of -40 degrees and up to +250 degrees Fahrenheit. The Neoprene duct materials allow the insulated ducting to have a compression ratio of 5 to 1. This means that a 25 ft length of this flexible air duct can compress effectively into a 5 ft coil! This hose is also manufactured with flame retardant materials, increasing the safety factor of the product. Inherently flame resistant fibers are materials that have flame resistance built into their chemical structures. For inherently flame resistant fibers, the protection is built into the fiber itself and can never be worn away or washed out.

The “Wind Handler Insulated TU” insulated ducting is made to order in custom lengths. This hose comes in yellow and features the black external wear-strip. The flexible air duct features standard cuffed ends, and belted finishes are also available for an additional charge. Available ID sizes for this insulated duct range from 4 inches to 40 inches and custom sizes up to 48 inches are available upon request. This product is great for use in air applications such as use in A/C ventilation, HVACs, mobile cooling units, plastic bag machines, shipyard work, and tent cooling.

What Is the R-Value of Insulated Ducting?

The R-value is a unit of measurement that determines how effective an insulated product’s ability is to resist heat flow. If an insulated flexible hose has a high R-value, it means it has a high thermal resistance and can reduce heat loss. On the other hand, if a flexible hose has a low R-value, it cannot reduce heat flow and allows heat to seep through the hose wall. Finding an insulated material’s R-value is, without a doubt, the best way to measure how an insulated material can resist conductive heat flow for your specific application and environment. To find the R-value for flexible duct insulation, it is usually found on the product’s manufacturer’s specification sheets. However, if it is not there, there are several ways to evaluate an insulation’s R-value. The standard way of determining an insulated material’s R-value is to divide the thickness of the insulation material (either in meters or inches) by the rate at which heat flows through it (either by watts per square meter or BTU per hour per square foot). By utilizing this formula, you can precisely and accurately measure the thermal resistance of your product’s insulation and find its respective R-value. However, for those who wish for an easier way to determine an insulated material’s R-value, the general rule of thumb is to examine the insulated material’s thickness. If the insulation of a flexible hose is thick, it means your duct has a high R-value; however, if a flexible duct insulation has a low R-value, the insulation must be thin. By determining an insulated flex hose’s ability to resist conductive heat flow, operators can choose the correct insulated flex hose for their intended application.

Screw Clamps

“Bridge Clamps”

What Is a Good R-Value for Ductwork?

The higher the R Value, the more insulation provided, for this reason hoses with insulated that have higher R-Values are preferred over lower ones. For instance, residential HVAC systems in colder climates will require an insulated hose with a high R-value rating to take account of sudden seasonal weather changes. On the other hand, residential HVAC systems in consistently warmer climates will require flex hoses with a lower R-value rating to ensure that their system covers only what is needed. There is a common misconception that every insulated ductwork should possess the highest possible R-value to maximize an HVAC system’s energy output and efficiency. While it is true that having a high R-value for your flex hose does make HVAC systems work more efficiently and use less energy, there is a certain point that having too much insulation can become redundant and have a negative effect financially and in practicality. For example, installing an over-insulated flexible duct in tight spaces, such as an attic, will make it much more difficult to repair should these flexible hoses require any timely or immediate maintenance. While there is no definitive standard for R-value ratings that encompasses all insulated ducting applications, consumers must choose an appropriate amount of insulation for their flexible ducts that should cover the minimum requirements for their environment and intended application.

“J-Lock Connectors”

- Ultra durable 304 stainless steel

- Quickest way to connect and disconnect hoses

- Designed with a raised lip to prevent hose clamp from slipping off

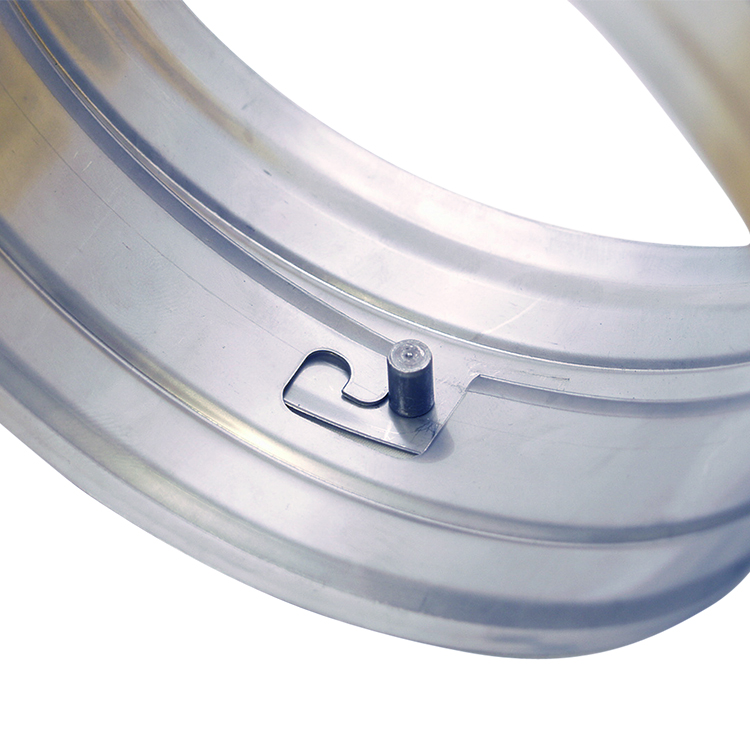

J-Locks connectors are a flexible duct connector that can quickly connect or disconnect two hoses of the same ID size. J-Lock Connectors are ideal for migratory applications that may require the assembly of longer hose lengths into one continuous coil. This type of hose connection allows shorter lengths of hose to be assembled into longer runs quickly and easily. In addition, these hose connectors are affordable duct accessories that not only are ultra-durable but also reduce overall assembly costs. Rather than investing in longer continuous runs of custom-made hose, operators can purchase standard 25ft. lengths and connect them using the J-Lock connectors to achieve desired hose lengths.

Unlike other hose connectors, this duct connector allows the operator to detach two hoses without the painstaking process of un-clamping the hose from the connector. As specified by its name, the “J-Lock Connectors” have a lock feature in the shape of the letter “J”; this feature allows the connection of a male end and female end with a simple twist. This hose connection is also designed with a raised lip to prevent the hose clamp from slipping off when clamped over the flexible duct. “J-lock” hose connectors are easy to use tools that reduce downtime and improve onsite installation performance.

“Tornado Flex Insulated AD”

“HVAC Insulated-Flex”

How Much Heat Is Lost in Ductwork?

For homes that utilize a non-insulated HVAC duct, they can lose up to 40% of generated heating and cooling energy. This loss of climate-controlled temperature is referred to as “heat loss.” Heat loss refers to the occurrence when climate-controlled air is slowly lost as it is transferred from the HVAC system to its intended destination. Without any insulation to slow down or prevent heat flow, any climate-controlled air transferred throughout a non-insulated hose will seep through the hose’s wall and can ultimately cause HVAC systems to operate 50% harder to make up for the loss. This will likely result in residential and commercial properties generating higher utility and energy costs to compensate for lost climate-controlled air. While installing non-insulated ducts is initially an affordable option, this type of flexible hose can generate higher utility costs in the long term, especially if it is utilized in residential and commercial properties in extremely hot and cold climates. The only scenarios where a non-insulated duct is popularly used are in applications that purely require operators to ventilate and exhaust high-temperature air and fumes, such as dryer vents and smoke ducting. As a result, non-insulated flex ducts should only be considered for applications that don’t require climate-controlled temperature air transferred in residential or commercial properties.

“Tornado Flex Insulated AD”

- Ideal use for permanent and mobile air conditioning units

- PVC material resists ozone, UV rays, and moisture

- Compressibility allows for convenient storage

- Wearstrip offers additional external abrasion & drag resistance

The “Tornado Flex Insulated AD” is an insulated hose made from two single-ply PVC coated yellow polyester fabric ply protecting insulation barrier, covered with an external wear-strip and reinforced with a spring steel wire helix. This makes for a hose that is both insulated and very durable, a unique characteristic of this product. In addition to its resilience, this flexible air duct exhibits excellent flexibility, allowing it to be used in tight or unusual installations. Unlike other rigid insulated products, this hose can easily make bends and turns in tight cramped spaces. The insulation and external abrasion resistance make this UV resistant hose ideal for permanent and mobile air conditioning units.

The PVC material used in this product offers good resistance to moisture, ozone, and UV rays. Its strong and durable design also makes this flexible air duct ideal for outdoor or indoor applications. PVC is resistant to many alcohols, fats, oils and aromatic free petrol. It is also resistant to most common corroding agents including inorganic acids, alkalis and salts. However, PVC should not be used with esters, ketones, ethers and aromatic or chlorinated hydrocarbons.

What Ductwork Needs to Be Insulated?

Insulated ductwork should be used in applications that require minimum heat loss when air is transferred through the ducts. Trying to determine which kind of ductwork should be insulated is going to be largely dependent on the intended application and desired results. For instance, residential and commercial HVAC systems should utilize insulated ductwork to deliver climate-controlled air appropriately and to dampen any noise generated from the HVAC system. The only time when you need to install insulated ductwork is unless there is a practical passive functionality to it, such as preventing heat loss and noise dampening. Common insulated flex ducts tend to have less flex and when flexed continuously, their lifespan decreases. In cases that continuous flexing is required, there are specially ducts that can be employed and standard insulated HVAC ducts should not be used.

“Silico-550 Insulated”

-

- Insulated Industrial dryer hose

- Combines flexibility with minimal heat loss

- Excellent external abrasion and chemical resistance

The “Silico-550 Insulated” hi-temp hose is suited for air handling applications and offers excellent external abrasion and chemical resistance. The Silico-550 Insulated high temp flexible hose consists of two layers. The inner layer consists of double-ply silicone coated woven fiberglass fabric with a spring steel wire helix. The outer layer consists of single-ply neoprene impregnated polyester fabric reinforced with a spring steel wire helix. These two layers are separated by 1-inch fiberglass insulation (R-value is 4). The flexible insulated duct is designed for fume conveyance in industrial air movement applications. In industrial use, this flexible insulated duct allows for minimal heat loss, while maintaining good flexibility and protection from external abrasions and harsh chemicals.

The “Silico-550 Insulated” hi-temp hose has a wide working temperature range. The industrial ducting is designed to withstand temperatures of high and low extremes. The inner layer of the high temp flexible hose has a range of -65 to +550 degrees Fahrenheit (+600 F intermittent). The outer layer of the flexible insulated duct has a range of -40 to +250 degrees Fahrenheit. Not only is the high temp flexible hose able to withstand extreme environments, it is also able to remain flexible without suffering from heat loss.

“Screw Clamps”

Can You use an Insulated Flex Duct for a Dryer Vent?

There are some cases where an insulated hose is not required for every residential ventilation application. Dryer ducting, for example, is a popular case where many homeowners consider using insulated flex hoses to ensure that the heat generated from a dryer does not seep through the hose wall and create an uncomfortably warm environment in their respective rooms. While the sentiment is understandable, dryer ducts do not require an insulated hose because it will increase maintenance costs should the flex duct ever get damaged over time. Dryer ducts are made to move lint and other materials, while insulated ducts are made to move air. In addition, there is a misconception that installing an insulated flex duct for dryers is enough to keep the hose clean. Using an insulated flex duct for a dryer vent makes no difference in the hose’s ability to maintain its cleanliness, and homeowners will still have to perform some timely upkeep to ensure that their dryer hose is lint-free and not clogged

“Aluminum Connectors”

- Light and easy to handle

- Affordable and cost-effective when compared to stainless steel connectors

- Available in sizes 1.5″ to 24″

“Aluminum Connectors” are a straight union hose connector that a duct gets clamped down onto without the need for special tools. Aluminum is a relatively soft, durable, lightweight, ductile and malleable metal that makes for an easy to handle product. Our aluminum hose connections have a typical aluminum appearance of dull gray, are nonmagnetic, do not easily ignite, and handle above ambient temperatures. Furthermore, it is one-third the density and rigidity of steel, ideal for applications that require more flexibility. Aluminum duct fittings make sense from the standpoint of cost and longevity.

Aluminum hose connections are used to connect or extend two hoses of the same ID size together. Once connected, the hoses are able to provide the necessary flow over longer sections. The hose connector is designed with a raised lip to prevent the hose clamp from slipping off. These are very affordable duct fittings, which makes adding hose connections a less costly venture when compared to buying longer lengths of custom-made hose. Due to the availability of sizes (1.5″ to 24″ID), these connectors can be used for a number of applications. When compared to stainless steel connectors, the aluminum connectors are more affordable, lighter and a better buy for general air ventilation applications.

“J-Lock Connectors”

What Is the Best Duct Insulation to Prevent Condensation?

Duct sweat is usually generated when outdoor humidity levels rise, and warm moisture-filled air comes into contact with cold ductwork. It is a natural process that generally occurs in humid climates, so when a significant amount of duct sweat is generated, it usually means the ductwork is experiencing leakage, blockage, or poor insulation. Ductwork condensation is a common issue found in homes and commercial properties across the country, and while a small amount of condensation will not cause irreparable damage, a large amount of it is typically a sign of a more significant issue.

If duct sweat is not appropriately dealt with, it can damage the insulation within your flex hose and begin accumulating bacteria in the wet insulation. One of the best ways to fix this problem is to ensure that your flexible ducts are properly sealed and installed because this can drastically reduce the chances of duct sweat from generating. Utilizing insulated flex ducts is another secure way to prevent duct sweat from forming because it prevents warm, humid air from coming into contact with the cool metal ductwork. While there will always be concerns for homeowners in warmer and humid climates on whether their HVAC flex duct is profusely sweating due to some leakage, by properly installing durable, insulated flex hoses, you can ensure your home is reliably outfitted to handle all your flexible ducting needs no matter what kind of climate you face.

“Bridge Clamps”

- Stainless steel band & welded stainless steel bridge with carbon steel screw

- Fits over the helix creating a leak proof seal

- Available in clockwise & counter-clockwise

- Available in sizes 2” to 12”

In addition to our hose and duct products, Ducting.com offers essential hose and duct accessories intended to increase your efficiency and productivity. While selecting the appropriate flex hoses for your application, it is also imperative to consider which accessories are required for the job, for instance, the types of hose clamps needed. One type of clamps we offer are the “Bridge Clamps” which are used to secure hoses onto a pipe or connector. Bridge clamps are used to secure hoses at connection points, and since the flat band clamps snugly around the material between the raised helix of the hose, a more secure connection is made possible.

Contrary to aluminum, stainless steel is an important alloy with many beneficial usages because of its excellent characteristics. Stainless steel is embedded with a significant amount of chromium, which then creates a passive and thin layer of chromium oxide that acts as a barrier to prevent damages to its surface. This is how stainless steel retains its luster and attractive appearance over a long period of time.

“Stainless Steel Connectors”

Screw Clamps

How Much Money Does Insulating Ductwork Save?

According to the EPA (Environmental Protection Agency), you can save an average of 15% of heating and cooling costs by incorporating an insulated hose into your HVAC system. While the performance and overall energy costs of our HVAC systems are going to vary based on your natural environment and seasonal climate, the fact that you can save several hundred dollars in utility bills makes using insulated flex ducts a much-needed cost-saving measure. With that in mind, an insulated HVAC duct has become a much-needed staple in every residential and commercial property and has revolutionized how we approach and control air temperature for personal comfort. Whether you consistently generate heat to warm your house or occasionally cool down your room on a hot summer day, insulated ducting can be used in a myriad of climate-control applications and confined space ventilation. If you are searching for insulated flexible hoses for your HVAC and flexible ducting needs, be sure to choose a hose that has a significant R-value rating and that the hose meets all your machinery’s requirements.

“Stainless Steel Connectors”

-

- Ultra-durable stainless steel construction

- Can be used in high temperature applications

- Designed with a raised lip to prevent hose clamp from slipping off

- Available in sizes 2″ to 12″

Ducting accessories are important and often times necessary additions to pair with duct and hose equipment. One of the ducting accessories that Ducting.com offers is our “Stainless Steel Connectors.” These hose connectors are used to connect and/or extend two hoses of the same ID size together. Connectors are central to the productivity of industrial and commercial applications such as: ventilation ducting, mine ventilation, chemical fumes exhaust and high temperature applications. These duct accessories allow for hoses to attach together to make longer runs using multiple hose coils of the same size. “Stainless Steel Connectors” are utilized specifically as straight union hose connectors or duct connectors.

As the product’s name suggests, these hose connectors are made from ultra-durable stainless steel. Compared to our Aluminum Connectors, Stainless Connectors are more heat resistant, offer better corrosion resistance, and are far more durable in outdoor environments. Stainless steel’s resistance to corrosion and staining, low maintenance requirements, and brilliant luster make it an ideal material for many applications.