“Urethane Flex Heavy-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

“Urethane Flex Self Extinguishing”

“Urethane Flex Static Dissipative”

What is Material Handling?

The act of material handling and collection is referred to as the act of moving, protecting, and controlling materials and byproducts from one location to another. Every material handling application requires equipment and machinery such as pumps, fans, and extraction units to facilitate the movement of these materials. Material handling is not strictly limited to transferring and distributing raw materials in industrial settings; it is also applicable in residential and commercial settings in the form of sanitation and ventilation. From residential dryers ventilating hot air and lint outside to agricultural facilities extracting and distributing food and grains to and from silos, material handling movement encompasses everything that requires transferring materials through flexible hoses and a series of ductwork. When determining what kind of flexible hose is needed for material collection and handling, there are several factors to consider, such as material composition, application compatibility, and size and length. However, the main factor to consider when choosing a material handling hose is its negative pressure capacity.

“PVC Flexduct Medium-Duty”

“PVC Flexduct Light-Duty Blue”

Understanding Negative Pressure

Negative pressure is the condition where air pressure is significantly lower in one area while another area is higher. Most material handling hoses and equipment utilize negative pressure to create a suction in order to collect and extract materials. Depending on the application, the power output and negative pressure capacity will vary widely; however, the best way to determine what kind of flexible duct you need to match your needs is by finding the hose’s ability to pull pressure which is measured by inches of mercury. This measurement, Inches of Mercury (IN./HG), is used to determine a flexible hose’s atmospheric pressure level. If a duct has a high inch of mercury level, then it means the material handling hose can withstand high levels of negative pressure. On the other hand, if a material collection hose has a low inch of mercury level, then it means the flexible hose cannot withstand significant levels of negative pressure, and depending on the hose’s material composition, it might possibly collapse in on itself. This is why most industrial facilities and workshops utilize flexible ducts with a high inch of mercury to assure operators they are efficiently transferring materials at a steady pace. It is essential to distinguish that negative pressure should not be confused with positive pressure and PSI (pounds per square inch). While the two may seem very familiar, they differ in functionality, with positive air pressure utilizing PSI to push and blow materials from a collected area through a duct to a contained area and negative pressure using suction to pull materials to a collection area. Keeping these functionalities in mind, positive and negative air pressure measure airflow and pressure differently, and as a result, they are utilized differently depending on the application.

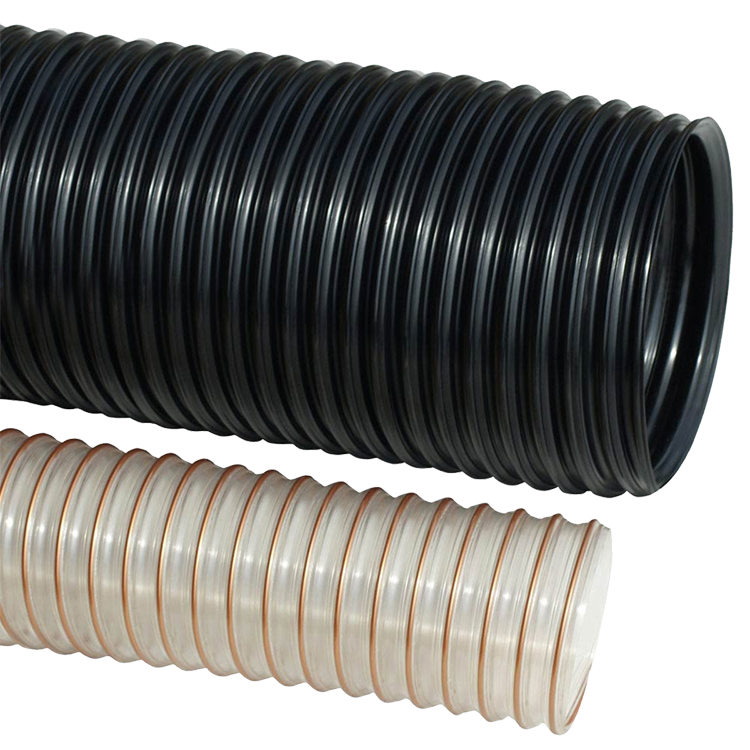

“PVC Flexduct General Purpose Clear”

- Great flexibility with tight bending characteristics

- Good chemical and moisture resistance

- Excellent compressibility

- Excellent choice for ventilation applications, dust & fume removal

The “PVC Flexduct General Purpose Clear” is a cost-effective PVC hose suitable for a wide range of light to medium duty air, dust, and fume related applications. The body of this clear flexible hose is made from PVC material and is reinforced by a steel wire helix. The clear PVC material provides these air and dust collection hoses a moderate degree of chemical and moisture resistance.

This PVC ducting is very flexible. It has a high bend radius that will allow you to carry out your air/dust collection application in the most difficult to reach areas. Since it is a highly compressible PVC hose, it is ideal for easy storage and can be moved from one job to the next. One of the biggest benefits of having a clear flexible hose such as this is due to the fact that you can keep an eye on what is going through the hose itself. You can easily spot any clogs or blockages that may occur within these dust collection hoses, allowing you to identify and fix the problem. Another great advantage this PVC hose has over other similar competing products is its cost-effective pricing.

Screw Clamps

“PVC Flexduct General Purpose Blue”

“PVC Flexduct General Purpose Clear”

“PVC Flexduct Heavy-Duty”

“PVC Flexduct Light-Duty Clear”

The Importance of Anti-Static Hoses

No matter what kind of material collection hose you decide on, choosing a flexible material handling hose with static dissipation features is always worth considering because of its practicality and its ability to prevent static-related incidents. Static buildup is when friction generates an electrical charge between two materials. As material handling hoses collect various abrasive debris and raw materials, the possibility of a static buildup generating is highly likely. While static electricity may not seem like a huge issue, it is a significant safety concern for industrial facilities that handle and transfer flammable materials daily. If industrial facilities do not utilize a static dissipative flex hose, an electrical charge can build up and can either short-circuit the machinery or ignite the material and cause a massive fire and eventual explosion. Considering these manufacturing facilities’ size, a slight static discharge in some flammable material transfer can yield devastating results. However, all of this is avoidable and manageable when utilizing anti-static ducts such as the “Neoprene Flex Conductive Static Dissipative” hose. These flexible hoses are made from conductive materials, which prevent any static buildup by allowing electrical energy to escape through the hose wall. By incorporating a static dissipative flex hose into your material handling applications, you can prevent static-related incidents and ensure your equipment’s circuitry is protected and operating at maximum capacity.

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Ideal for clean room and material plastic processing applications

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.

“Urethane Flex Extra Heavy-Duty”

“Urethane Flex Heavy-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Self Extinguishing”

How to Choose the Appropriate Material Handling Hose?

For this you need to know what is going through the hose, the temperature of the media being moved, the temperature of the parts of the equipment that the hose will be attached to, the inside diameter of the hose required and the length of the duct. When choosing an appropriate material handling hose, picking a flexible duct suited for your intended application and your machinery’s requirements is important. You need to take account of the application to avoid purchasing a material handling hose that is not catered for your machinery and its operational standards. For instance, choosing a flexible drainage hose for food-grade ducting will not only result in encountering operational issues but it may cause harm to those consuming the food materials. If the materials were to be shipped and produced for mass consumption, thousands would become sick when they consume the contaminated food. Another example would be using aluminum flex hoses for suctioning and material collection. As material extraction and collection utilize negative pressure, using an aluminum flex hose will result in the hose caving in on itself due to the high atmospheric pressure generated through industrial machinery, rendering the flexible ducting useless. Considering these scenarios, choosing a material handling hose is vital to ensure your application’s production efficiency and maintain your equipment’s functionality.

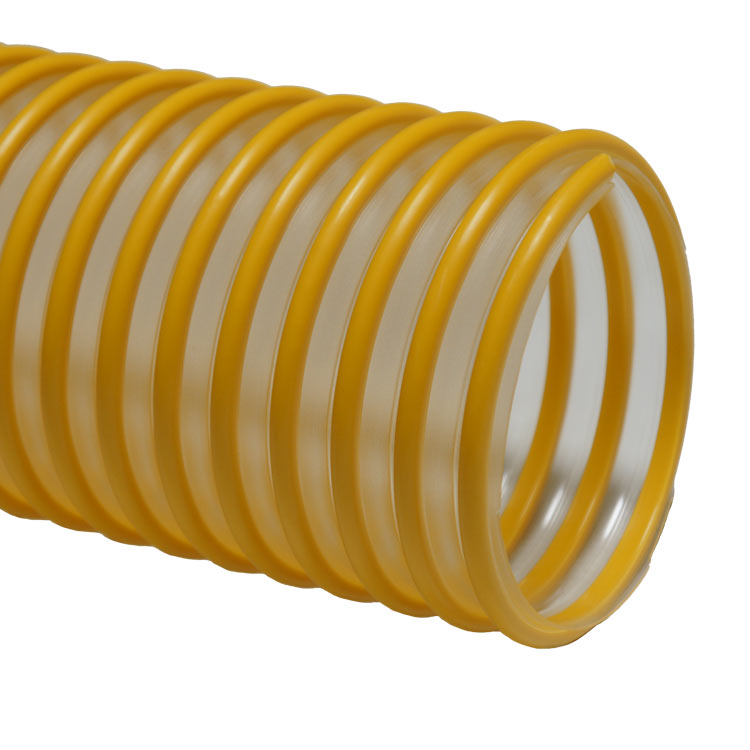

“Urethane Flex Medium-Duty”

- Great abrasion resistance & high tear strength

- Superior chemical resistance

- Excellent flexibility

- Designed for applications with wide temperature ranges

The “Urethane Flex Medium-Duty” is a polyurethane duct designed for abrasives, dust, and material applications. These dust collection hoses are made from medium-weight polyurethane wall material reinforced with a bronze coated spring steel wire helix. The polyurethane hose materials used in this product give it excellent protection against chemicals and abrasion (external and internal).

This is our best selling polyurethane duct because it combines flexibility, chemical resistance, and abrasion resistance. The high tensile strength of polyurethane also assures reliability and durability when using this product. Because polyurethane duct is tough, it can have thinner gauged walls when compared to rubber or vinyl. This polyurethane duct also has excellent resistance to hydrocarbons, chemicals, ozone, bacteria, fungus, moisture, and skin oils. This material handling hose is available in clear, which utilizes FDA acceptable materials (ideal for food and drug applications).

“PE Flex Translucent”

“Neoprene Flex – 2 ply”

“Neoprene Flex – 2 ply Heavy-Duty”

“Neoprene Flex – 1 ply”

Suction Hoses – Designed for Extraction

If your application requires you to extract and collect materials and debris, then a suction flex hose is the best-suited duct for this material handling application. Whether you are extracting materials for manufacturing purposes or collecting trash and debris for sanitation purposes, a suction flex hose needs to be specifically designed to withstand the negative pressure your machine generates, or else the hose will fail. For example, commercial vacuum cleaners and car washes utilize polyethylene flex ducts, such as the “PE Flex STM Flexible Vacuum Hoses,” because these flex hoses are capable of withstanding 29″ IN/HG, which is the maximum atmospheric negative pressure capacity. While flex hoses built from materials such as coated poly-fabric would not be able to function correctly under such conditions, the “PE Flex STM Flexible Vacuum Hose” can handle such conditions and even showcases a resistance to abrasion, crush, corrosion, and chemicals, which makes it ideal for many sanitation applications and related machinery. So, if you are searching for a durable suction flex duct for extraction and collection purposes, be sure to choose a duct made from materials such as polyurethane, PVC, and thermoplastic.

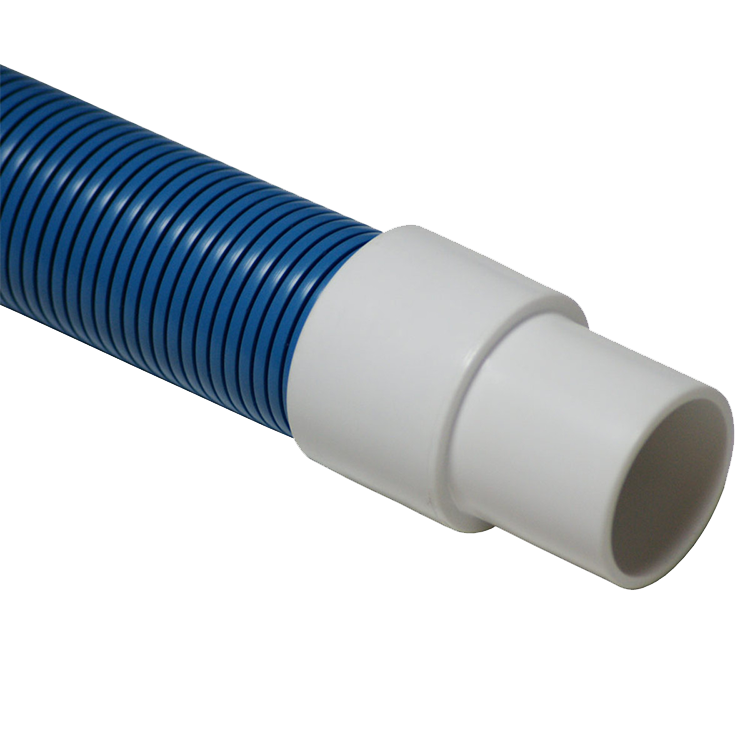

“PE Flex STM”

- Double profile I-Helix construction for easy movement on surfaces

- Ideal for both truck-mounted and portable carpet cleaning units

The “PE Flex STM” flexible industrial ducts are recommended for light bulk material handling applications. The orange or blue hose is made using a highly durable polyethylene copolymer. The hose wall has been reinforced with an integral polyethylene helix, designed for materials transportation. The double profile 1-Helix construction allows for easy movement on surfaces, which makes this vacuum hose ideal for both truck-mounted and portable carpet cleaning units.

These extraction hoses are flexible, crush resistant, and offer superior abrasion resistance. Abrasion can wear away the interior and exterior of a hose by scuffing, scratching, wearing down, marring, or rubbing it away. Abrasion is highly undesirable and can lead to premature wearing and failure. The construction of this hose provides great protection against these types of abrasion, making it ideal for most commercial applications. Additionally, the vacuum hose is designed to resist corrosion caused by the combination of hot water and chemical concentration of detergents. The “PE Flex STM” flexible duct-work is available in both 1.5 and 2 inch internal diameters with tolerances between -0.00 to + 0.050 Inches. The smooth interior of the flexible industrial ducts allows for an efficient level of air to flow through it. This means that both hose sizes are capable of handling a full vacuum. This allows for its use in a wide variety of industrial and commercial applications. These extraction hoses have a wide range of working temperatures from – 40 Fahrenheit to +160 Fahrenheit.

Food Grade Hoses

Food-grade hoses are flexible ducts specifically designed to transfer dry food materials hygienically and without contamination. These flexible ducts adhere to the strict guidelines enforced by the FDA (Food and Drug Administration) to avoid contamination and degradation. According to the FDA, food-grade hoses must be made from non-toxic and approved materials such as thermoplastic rubber, polyurethane, and PVC. Because these materials offer a natural resistance to chemicals, moisture, and extreme temperatures, all of which are usually encountered in food distribution faculties. Food-grade hoses should be produced in either a translucent or white color to assure inspectors and operators that the ductwork is made from materials with high purity. An FDA-approved hose must also feature an odorless and tasteless design to ensure that the integrity of raw food materials is preserved and not altered in any way, shape, or form. As a flexible ducting option for material handling, food-grade hoses are meant to transfer and extract dry food grains and materials to mass-produce food for general consumption. With that in mind, agricultural farms and facilities must utilize FDA-approved ducting, or they risk creating an incident that could harm people’s health.

“Thermoplastic Flex White”

- Good abrasion resistance

- Great moisture & UV resistance

The “Thermoplastic Flex White” is a medium-weight material handling hose that is great for abrasive, dust, and material collection applications. This product is specifically made from FDA acceptable hose material, which makes it suitable for food and drug-related applications. The thermoplastic rubber used in this product provides good chemical and heat resistance, and is also able to withstand higher temperatures than ordinary rubber products. Thermoplastic rubber refers to a class of copolymers that are made from a mixture of plastic and rubber. This combination results in a material that offers good chemical and UV resistance. This thermoplastic hose is also reinforced with a spring steel wire helix for added protection and stability. This resilient quality is important when using the food grade hose in rough and unforgiving environments. The smooth interior of this hose material allows for minimal friction loss and provides efficient airflow.

The “Thermoplastic Flex White” can be used as a dust collection hose in both high and low temperature environments. This thermoplastic hose has an operating temperature range of -40 degrees to +250 degrees Fahrenheit and is intended for environments that ordinary hoses cannot withstand. This product comes in a white color, which provides good visibility for food grade applications.

“PVC Flexduct Light-Duty Clear”

“Silico-Fiberglass 550”

“Silico-550 Double Ply”

“Silico-550 Nomex”

“Silico-550 Single Ply”

Dryer Ducting

Dryer ducting is a type of material handling ducting designed for residential and industrial dryers to vent out hot air, moisture, and lint. Dryers are a different kind of material handling equipment because a dryer’s purpose is to vaporize absorbed moisture from wet materials and then transfer that vaporization and excess heat outside to prevent the moisture from accumulating inside and creating bacteria and corrosion. While most dryers vent out and exhaust heat, lint is one of the most common materials that dryer ducts transfer. As a material, many see lint as a nuisance when they are doing their laundry; however, it is incredibly crucial that dryer ducts properly vent out the lint to prevent lint-related fires from occurring. According to the NFPA (National Fire Protection Association), lint-related fires cause an average of 16,000 yearly due to the material’s flammability. Considering how this light, flimsy material can drive so many incidents in a residential setting, it is vital for people to clean out their dryer’s lint filters. Whether it is for residential or industrial dryers, they both require a flexible hose that is designed to withstand extreme heat and exhibit a lightweight construction to ensure proper airflow. Aluminum flex ducts, for instance, are among the most popular ducting options for dryers due to their lightweight design and self-supporting construction. These flexible ducts are readily available in a large assortment of inside diameter (I.D.) sizes and lengths, which makes them one of the most accessible ducting options compared to other material handling hoses made from silicon and acrylic. If you are searching for a collection hose for your dryer duct, be sure to go with one that can handle the heat and the lint.

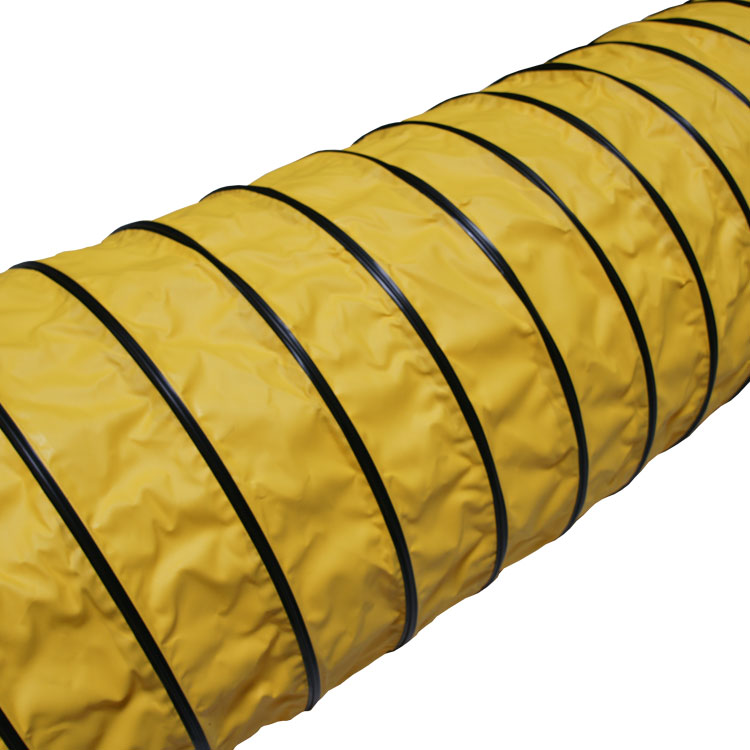

“Acrylic 325 Flex Air Handler”

- Ideal for moving large volumes of air in portable or permanent ventilation/exhaust systems

- Wearstrip offers additional external abrasion & drag resistance

- Retractability allows for convenient storage & easy transport

The “Acrylic Flex 325 Air Handler” is a high temperature duct designed for air movement. Each flex hose is constructed from a single-ply acrylic coated polyester fabric. This makes for a flexible duct that is easily retractable. The flexible duct is protected externally by a black PVC wear-strip and reinforced internally with a spring steel wire helix. The durable steel wire coil gives the hose its strength and flexibility, allowing it to be easily utilized in a variety of industrial settings. The PVC wear-strip protects the exterior of the flexible high temperature hose from wear when being moved or dragged along the ground.

The “Acrylic Flex 325 Air Handler” flexible duct has a working temperature range from -20 to +325 degrees Fahrenheit. This is unique among air ventilation hoses because the hose can handle temperatures above ambient. The high temperature duct has excellent compressibility and is ideal for moving large volumes of air in portable or permanent ventilation and exhaust systems. Each high temperature flex hose is UL 94V-0 flame retardant. To be considered UL 94 V-0 flame retardant, hose material exposed to a vertical flame (which is removed after 10 seconds) must stop burning within 10 seconds of ignition without flaming drips. Each flexible high temperature hose is easily retractable allowing for convenient storage and easy transportation.

“Silico-Fiberglass 550”

“Silico-550 Single Ply”

“Silico-550 Nomex”

“Silico-550 Double Ply”

“Acrylic Flex 325”

“Acrylic Flex 325 Pharma”

“Acrylic Flex 325 Air Handler”

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Blue”

Drain Ducts

For material ducting applications that require wastewater and liquid debris to be transferred, moisture-resistant drain ducts are going to be your best option. Drain ducts are designed to collect and transport sludge and fluids for sanitation purposes, and they serve as a standard workplace installment for various environments, such as commercial kitchens and pool cleaning services. With that in mind, these material ducting hoses must be durable, flexible, and resistant to clogging. For example, our “Smooth-Tube” series is a perfect example of a flexible hose designed to prevent clogs and blockage from occurring due to the hose’s smooth interior. The “Smooth-Tube” flex duct also features a clear translucent design that allows operators to detect clogs should they ever occur, and this design choice is beneficial for operators to cut down on their maintenance downtime. However, if you are searching for a more budget-friendly alternative for your flexible material handling hose, then “PVC Flex Ducts” are the most cost-effective ducting options due to the material composition. While it is important to note that “PVC Flex Ducts” are not as durable as other drain ducting options, they are also one of the easiest to replace should they become damaged beyond repair.

“Smooth-Tube PU”

- Highly abrasive resistant, smooth interior hose.

- Excellent flexibility and puncture and crush resistant.

- External helix acts as wearstrip, protecting the outside of the hose.

- Excellent anti-microbial properties.

The “Smooth-Tube PU” material handling hose is a medium weight duct that is made up of polyurethane film. A great hose for dust collection and other material handling applications, it features a smooth interior that maximizes the level of flow in the tube. It is a very abrasion resistant hose thanks to its polyurethane makeup and its external wearstrip. Overall, this flexible ductwork is a great choice for your dust and material handling needs.

Consider carefully the benefits of having a smooth interior on a flexible hose for material handling. A smooth interior area means that the hose does not have any uneven ridges or corrugations. Such uneven surfaces can invite finer materials to get caught inside and clog up the flex duct. This can be a huge problem that will hinder the efficient functioning of your application. Particles will not get caught or form clogs on smooth interior surfaces of this hose due to its smooth bore. Inside, the material handling hose will benefit greatly from a superior and efficient level of airflow.

“Thermoplastic Flex White”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex Medium-Duty”

“Thermoplastic Flex Light-Duty”

“Thermoplastic Flex Heavy-Duty”

“Thermoplastic Flex Extra Light-Duty”

“Thermoplastic Flex Heavy-Duty”

Dust Collection

Dust collection is a type of material handling application that is geared towards sanitation efforts because collecting dust and debris is a vital step for industrial facilities and workshops to create a safe and clean work environment. Industrial dust is the byproduct of factories manufacturing and processing raw materials into finished products. No matter what kind of industrial dust is being produced, every type of industrial dust is a huge safety concern if inhaled. While the particle composition is going to vary from material to material, the damage it does to one’s respiratory system can cause irreversible chronic health conditions and long-lasting diseases. According to OSHA (Occupational Safety and Health Administration), industrial dust and debris such as metal, wood, and plastic are highly combustible. If dust collection systems do not utilize a static-dissipative hose, these materials likely ignite and create a hazardous environment. This is why dust collection systems need to utilize reliable material handling hoses in order to prevent such a scenario from occurring. Dust collection hoses such as thermoplastic flex hoses are a durable, inexpensive option that is great for collecting industrial-grade dust. These flexible hoses have a long, successful track record in a wide range of transferring abrasive debris and materials, and they can be used to improve sanitation efforts for industrial workshops and factories. As a flexible ducting option for material handling, thermoplastic rubber is one of the most relied-on materials in industrial settings.

“Thermoplastic Flex Light-Duty”

“PE Flex Translucent”

What is the Best Type of Material for Extraction Hoses?

When deciding what kind of material you should use for your material collection hose, the answer will ultimately vary on the application. Industrial applications that require high levels of negative pressure to extract materials from their source need extraction hoses to be built from ultra-durable materials such as polyurethane and polyethylene to withstand the high-powered suction. Meanwhile, residential ventilation and light material collection need a general all-purpose flexible duct to handle daily applications at an affordable cost. A flexible residential hose made from PVC is an excellent, cost-effective material that can suit a multitude of applications, such as dust collection and drain ducting. However, specific applications that require you to follow government-approved guidelines, such as food-grade ducting, must utilize clear or white-colored flexible ducts to showcase the duct’s purity and ensure operators and inspectors that the duct will not contaminate any raw food materials. No matter what kind of flexible hose you choose for your application, it is crucial to utilize a flexible material handling hose designed to resist abrasive debris, chemicals, and extreme temperatures because these hoses must withstand the harshest environments to transfer demanding materials.

“PVC Flexduct Heavy-Duty”

- Clear is manufactured with FDA acceptable materials

- Excellent choice for ventilation applications, dust & fume removal

The “PVC Flexduct Heavy-Duty” is a heavyweight PVC wall hose reinforced with a spring steel wire helix offered in blue or clear. These flexible ducts are designed for light bulk material handling, heavy-duty ventilation applications, dust, and fume removal. This hose provides excellent internal and external abrasion resistance and is resistant to an array of chemicals and moisture. These heavy-duty hoses are great for applications where light materials will be handled and abrasion resistance is a must. Under normal conditions of use, the factor most strongly influencing the durability of PVC ductwork material is its resistance to oxidation by atmospheric oxygen. PVC (i.e., PVC Ductwork), having the molecular structure where the chlorine atom is bound to every other carbon chain, is highly resistant to oxidative reactions and maintains its performance over a long time.

The “PVC Flexduct Heavy-Duty” is a material handling hose product that is available in inside diameter sizes ranging from 1.25” up to 24” ID. This large range of ID sizes provides you with a heavy-duty hose that is great for a variety of applications, such as fume ventilation, dust collection, pharmaceuticals, and lawn and leaf collection. These heavy-duty hoses are available in blue and clear in standard 25-foot and 50-foot sections with plain cut ends.