“Urethane Flex Medium-Duty”

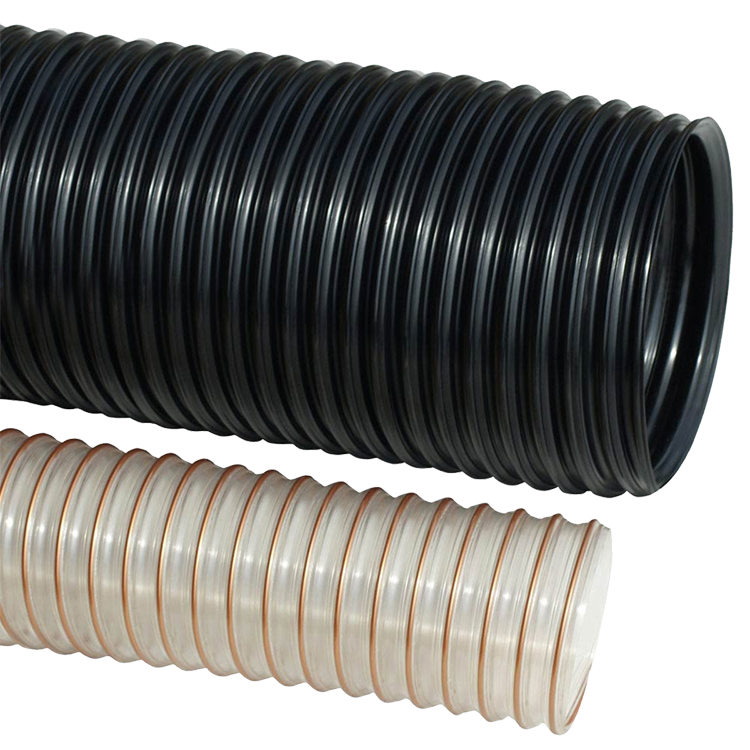

“Thermoplastic Flex Medium-Duty WS”

“Urethane Flex Light-Duty”

“Urethane Flex Heavy-Duty”

“PVC Flexduct Light-Duty Clear”

“Thermoplastic Flex Medium-Duty”

“PVC Flexduct Heavy-Duty”

“Neoprene Flex – 2 ply”

“PVC Flexduct Light-Duty Blue”

Screw Clamps

What Is a Metric Size?

A metric size refers to the standard of measuring or evaluating something that aligns with the metric system. The metric system is a measurement system that utilizes decimals to determine the length and weight of objects. The system was inspired by Gabriel Mouton, who first proposed a natural standard of length based on the circumference of the Earth divided decimally. The system was eventually refined and devised by a group of French scientists in an effort to create a standardized system of dimensions. During the French National Assembly in the 1790s, Charles Maurice de Talleyrand proposed the standardized system, and while it was initially met with pushback, the system became adopted over time for its simplicity. Fast forward to today, around 95% of the world has officially adopted the metric system into their infrastructure and education system, and it is used to determine the weights and lengths of many different products and materials such as raw construction materials, bricks, furniture, and flexible hoses daily.

“Urethane Flex Heavy-Duty”

- This hose is in stock in 4”, 6” and 8” ID sizes and can ship in 24hours

- Great abrasion resistance & high tear strength

The “Urethane Flex Heavy-Duty” material handling hoses are designed to work in severe abrasive and material transfer applications. This flex duct is made from polyurethane duct materials, making it very durable and flexible. The diverse properties of polyurethane make it the leading choice for engineers looking for long-lasting materials for their high load, high stress environments. Polyurethane routinely outperforms plastic and rubber in its overall ability to resist harsh environmental factors such as abrasion, heat, solvents, oil and acid. Because of the PU material used in these material handling hoses, these products feature fantastic tear strength while maintaining excellent flexibility.

This flex duct is also available in a clear color that is made with FDA acceptable materials. This flexible ducting’s heavy wall makes it an ideal choice for heavy-duty applications involving abrasives. The “Urethane Flex Heavy-Duty” material handling hoses are designed to work within wide temperature ranges. This dust collection hose works in temperatures ranging from -65 to +225 degrees Fahrenheit. Even when working in low temperatures, this dust collection hose maintains excellent flexibility.

Why Do Americans Not Use Metric?

Despite 95% of the world adopting the metric system, the United States is the only first-world country yet to implement it in its infrastructure. This is because the Imperial system was widely utilized during the Industrial Revolution, and manufacturing plants developed products and materials using those measurements. The frequency with which this system was used eventually reached the point where the Imperial system became the measuring standard of America’s infrastructure and education system. While there were many cases created to switch from the Imperial system to the Metric due to its practicality and easy-to-understand nature, every attempt to switch unit systems was thwarted by big businesses and American citizens who did not wish to invest time and money to restructure the entire country’s infrastructure. As a result, many educational institutions resorted to teaching both the Imperial and Metric system in order to teach future generations something familiar and something new and practical. However, when directly comparing the two systems, the metric system is a much better standard because it is much easier to grasp as every measurement is based on multiples of 10.

“PVC Flexduct Light-Duty Clear”

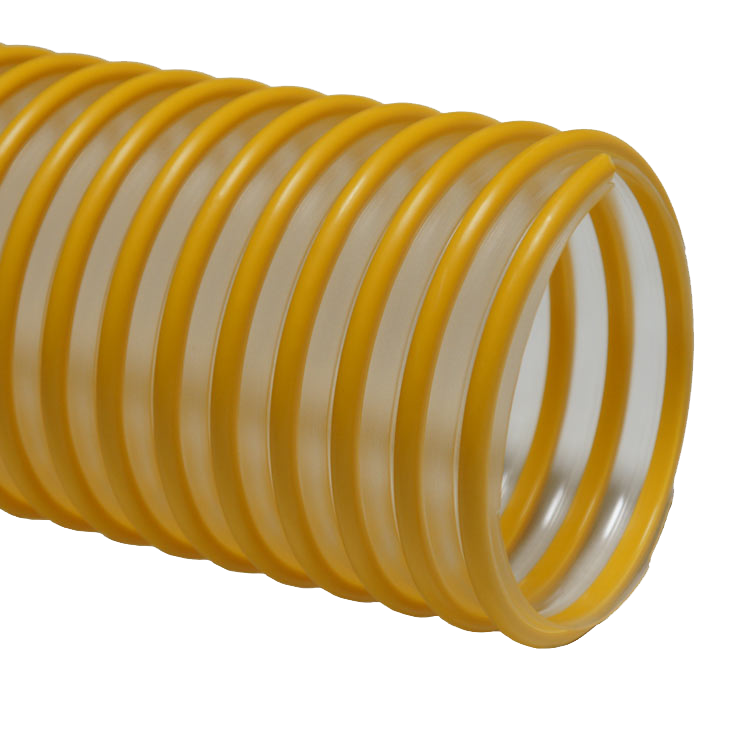

“Thermoplastic Flex Medium-Duty WS”

- Great general all-purpose hose

- Yellow wearstrip offers additional external abrasion & drag resistance

- Designed for applications with wide temperature ranges

“Thermoplastic Flex Medium-Duty WS” is a thermoplastic rubber duct designed as a great general-purpose material, air, dust or fume handling hose. This product is unique from other thermoplastic rubber duct products because it features an external wear-strip that offers additional external abrasion protection and drag resistance. The external wear-strip extends the product life by protecting the hose from external wear, which is often forgotten by end-users. This is one of our best selling products!

Thermoplastic rubbers are a class of copolymers that possess both thermoplastic and elastomeric properties, generally made from a mix of plastic and rubber. The thermoplastic rubber material gives this rubber hose great chemical resistance and also provides a longer life in extreme hot and cold environments over standard rubber. Thermoplastic vulcanizates (TPVs) have been proven to be dependable polymers for flexible engineered parts that require long-term performance. This hose is recommended for applications that require good chemical and abrasion resistance, such as dust and abrasives collection.

“Smooth-Tube PVC”

What Metric Ducts Sizes are available?

Here is a brief list of metric hoses available in Metric sizes and the sizes they are available in Metric Diameters. All diameter sizes are in millimeter and all Metric sized hoses have a 200 ft minimum order. All Metric hoses are made to order.

1. Thermoplastic Flex Medium Duty WS: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

2. Urethane Flex Medium-Duty sizes: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

3. Urethane Flex Light-Duty sizes: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

4. Urethane Flex Heavy-Duty sizes: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

5. PVC Flexduct Light-Duty Clear: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

6. Thermoplastic Flex Medium Duty: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

7. Neoprene Flex 2-Ply: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

8. PVC Flexduct Light-Duty Blue: 60, 80, 100, 120, 140, 150, 175, 200, 250, & 300mm

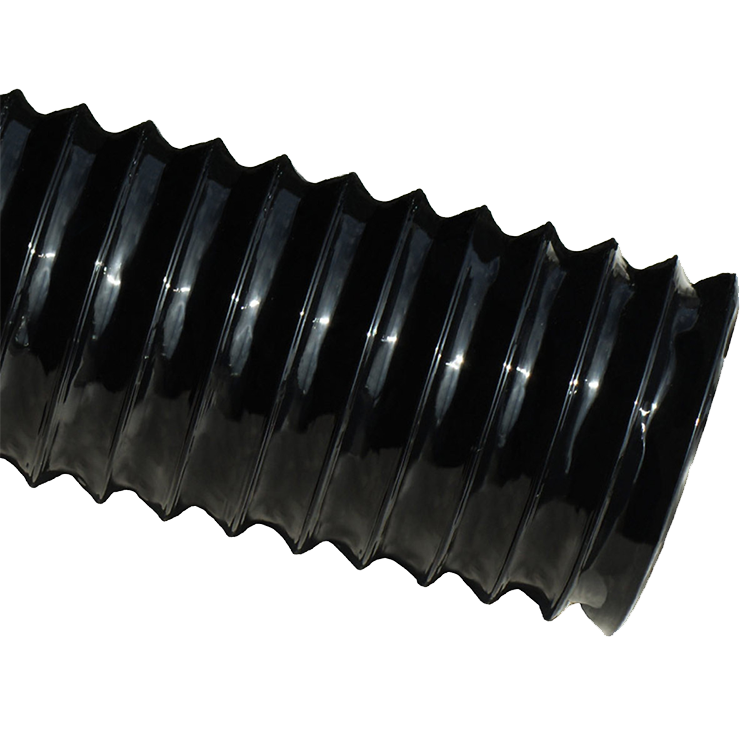

“Neoprene Flex – 2 Ply”

- Good crush resistance and tensile strength

- Neoprene coating offers excellent abrasion and chemical resistance

The “Neoprene Flex – 2 ply” industrial duct is recommended for dust control and material transfer applications. The large diameter flexible pipe is made using a strong double-ply neoprene coated polyester fabric with a spring steel wire helix. The intelligent construction and durable 2-ply neoprene wall allows these flex hoses to withstand abrasive dust and other harsh materials. This hose is recommended for use in a vast list of harsh conditions including dust collection, grinders, woodworking and furniture industries.

Each “Neoprene Flex – 2 ply” industrial duct has good crush resistance that allows it to be used in harsh environments. The flexible pipes tensile strength, or the maximum tension the material can withstand without tearing, is complemented by the excellent abrasion and chemical resistance offered by its neoprene coating. The “Neoprene Flex – 2 ply” flexible duct has good flexibility and is more durable than double ply cotton hoses. The flex hoses can handle both positive and negative pressures. Each industrial duct has a working temperature range of -40 F to +250 F and is listed as a UL 94 V-0 flame retardant product.

What Is the Difference Between Metric and Imperial?

When it comes to understanding the difference between the Metric and Imperial systems, the main difference is how they determine and define the length and weight of products and materials. The entire Metric system follows a decimal pattern based on powers of 10, which is categorized by either grams or meters. For instance, a decagram, kilogram, megagram, and gigagram are all separated by the multiples of 10; meanwhile, decimeters, centimeters, and millimeters are separated by the submultiples of 10. The Imperial system, on the other hand, is a measurement system used to determine units of weight and length based on the human form. For clarification, this means that Imperial units of measurement such as inches, pounds, feet, yards, and miles were all based on the average length and weight of a body part during its conception. As a result, calculating measurements on the Imperial system is more of an intuitive approach that requires people to remember the basic units of Imperial measurement, such as 12 inches to a foot, 3 feet to a yard, and 1760 yards to a mile. While this may seem counterintuitive and bothersome for those trying to convert Imperial measurements to Metric units, there are several formulas that can accurately determine the conversion between the two systems.

“PVC Flexduct Heavy-Duty”

“PVC Flexduct Light-Duty Blue”

“Thermoplastic Flex Medium-Duty WS”

“Thermoplastic Flex Medium-Duty”

“Urethane Flex Medium-Duty”

- This hose is in stock in a variety of sizes can ship in 24hours.

- Good compressibility

- Great abrasion resistance & high tear strength

This is our best selling polyurethane duct because it combines flexibility, chemical resistance, and abrasion resistance. The high tensile strength of polyurethane also assures reliability and durability when using this product. Because polyurethane duct is tough, it can have thinner gauged walls when compared to rubber or vinyl. This polyurethane duct also has excellent resistance to hydrocarbons, chemicals, ozone, bacteria, fungus, moisture, and skin oils. This material handling hose is available in clear, which utilizes FDA acceptable materials (ideal for food and drug applications).

The “Urethane Flex Medium-Duty” flexible duct is designed for applications with wide temperature ranges. These dust collection hoses work in temperatures ranging from -65 to +225 degrees Fahrenheit. The hose materials used in this product give it excellent flexibility when adapting to different environments, making it a great choice for a large variety of applications involving extreme temperatures. Urethanes feature superior flexibility over a wide durometer range, even at temperatures as low as -65°F.

“Urethane Flex Light-Duty”

What Is a Metric Hose?

A metric duct hose is a flexible duct where the inside diameter (I.D.) size is constructed and designed to follow the metric system sizing. These flex ducts are all custom-made to properly accommodate the sizing requirements of machinery and applications that abide by the metric system. Due to the sizing discrepancy between the two measurement systems, some flexible ducting may be limited to those utilizing metric sizing; however, many flex hose options are still available for those who want a metric hose. For instance, our “Urethane Flex” series is one of the many flex hose options that can be made in customized size to match the requirements of metric duct size. Whether you need flexible hoses for material handling applications such as woodworking, raw material extraction, or sanitation collection, our metric polyurethane flex hoses are built to withstand the daily rigors of these applications, plus any harsh or demanding environments associated with them. These flexible ducts are available in different weight classes, from Light-duty, Medium-duty, and Heavy-duty, and depending on your choice of product, these hoses can even be used in FDA-grade ducting applications. With that in mind, metric hose operators will not have to worry too much about finding some of the best metric ducting options on the market.

Screw Clamps

“Thermoplastic Flex Medium-Duty WS”

Here is a Quick Conversion of Imperial Duct Sizes into Metric Duct Size:

Sometime if you are in a rush and cannot wait for a Metric hose to be made for you, then an Imperial size maybe close and may work for you:

| Inches | mm |

|---|---|

| 2-Inches | 51mm |

| 2.5-Inches | 64mm |

| 3-Inches | 76mm |

| 3.5-Inches | 89mm |

| 4-Inches | 102mm |

| 4.5-Inches | 114mm |

| 5-Inches | 127mm |

| 5.5-Inches | 140mm |

| 6-Inches | 153mm |

| 2.5-Inches | 64mm |

| 3-Inches | 76mm |

| 3.5-Inches | 89mm |

| 4-Inches | 102mm |

| 4.5-Inches | 114mm |

| 5-Inches | 127mm |

| 5.5-Inches | 140mm |

| 6-Inches | 153mm |

| 6.5-Inches | 165mm |

| 7-Inches | 178mm |

| 8-Inches | 204mm |

| 9-Inches | 229mm |

| 10-Inches | 254mm |

| 12-Inches | 305mm |

| 14-Inches | 356mm |

“Smooth Tube PU”

- Highly abrasive resistant, smooth interior hose.

- Excellent flexibility and puncture and crush resistant.

- External helix acts as wearstrip, protecting the outside of the hose.

The “Smooth-Tube PU” material handling hose is a medium weight duct that is made up of polyurethane film. A great hose for dust collection and other material handling applications, it features a smooth interior that maximizes the level of flow in the tube. It is a very abrasion resistant hose thanks to its polyurethane makeup and its external wearstrip. Overall, this flexible ductwork is a great choice for your dust and material handling needs.

Consider carefully the benefits of having a smooth interior on a flexible hose for material handling. A smooth interior area means that the hose does not have any uneven ridges or corrugations. Such uneven surfaces can invite finer materials to get caught inside and clog up the flex duct. This can be a huge problem that will hinder the efficient functioning of your application. Particles will not get caught or form clogs on smooth interior surfaces of this hose due to its smooth bore. Inside, the material handling hose will benefit greatly from a superior and efficient level of airflow.

“PVC Flexduct Light-Duty Blue”

- Great flexibility with tight bending characteristics

- Good chemical and moisture resistance

The “PVC Flexduct Light-Duty Blue” is a medium-weight blue PVC wall flex duct reinforced with a spring steel wire helix for industrial air movement and fume control applications. This flex duct provides great flexibility with tight bending characteristics and offers good chemical and moisture resistance. PVC duct materials have an amorphous structure with polar chlorine atoms in the molecular structure. Chemical stability is a common feature among PVC duct materials containing halogens, such as chlorine, making this PVC industrial duct chemically stable. For precise substance resistivity of this hose please refer to our Chemical Resistance Guide.

The “PVC Flexduct Light-Duty Blue” is a light-duty hose option that is available in internal diameter sizes from 1.25” up to 24” ID. Metric sizes are also available. This large range of ID sizes provides you with a light-duty industrial hose that is accessible in almost any size! This light-duty industrial duct is available in blue in standard 25-foot and 50-foot sections with plain cut ends. If you have questions or need additional information about this air return duct, please do not hesitate to give one of our ducting specialists a call today.

How Do You Measure Duct Size?

Whether you are utilizing the Imperial system or Metric system, you need to measure the duct size to figure out what flex duct size is required for your machinery and application. The best way to measure the size of your flex duct is to find the flexible hose’s inside diameter (I.D.). To find the inside diameter (I.D.), take a measuring tool such as a tape measure or a ruler, and begin your measurement from the inner hose wall of your flex duct, and line it up to the direct opposing side of the flexible hose. The distance between the two opposing inner hose walls will be the inside diameter (I.D.) size. It should not be confused with the outside diameter (O.D.), which takes account of the measurement starting from the outer hose wall to the opposite outer end. Another popular misconception of determining the size of your flex hoses is by finding its circumference. Finding the circumference of a flexible hose is inefficient because it refers to the outside perimeter of a hose rather than the channel size of your machinery, where it transfers air or materials. By measuring the outside diameter (O.D.) or the circumference of a flexible hose for your application, you risk purchasing improperly sized ductwork that cannot be used efficiently.

How To Measure Ductwork

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

What Are Standard Duct Sizes?

Standard duct sizes vary from 25mm inside diameter to 610mm inside diameter. Custom sized hoses are available in up to 1322mm diameter. For clarification, there isn’t a universal duct size that covers all machinery and applications, and what size you need for your ducting will vary widely from case to case. The most popular duct size in the US is 4”, 6” and 8 inch diameters. Whether you utilize imperial or metric ducting, you need to correctly measure your machinery’s channel size to find a suitable flexible hose that can cater to your application. The best way to determine what size of ductwork you require for your application is by determining the machinery’s pipe size outside diameter (O.D.). This pipe size is where the duct fits over. By finding the pipe size’s outside diameter (O.D.), you can match it to the inside diameter (I.D.) of your flex duct. If all the measurements were accurately gauged, the flex duct should fit over the pipe snugly, and operators can install tightening clamps and attachments to secure the hose properly.

While most flexible ducting options can be effectively used in a general all-purpose setting, specialized applications such as material extraction require specific flexible ducts to ensure operators that their hoses are used to their fullest operational potential. For example, our “Smooth-Tube” series is an excellent ducting option that can be utilized for material extraction due to its completely smooth interior and abrasive-resistant exterior, making it ideal to use for industrial material extractors because the hose will not cave in on itself from the high atmospheric pressure generated.

“Urethane Flex General Purpose Black”

- Great compressibility

- Good abrasion resistance

Applications involving the transfer of materials, from light dust to larger solid wood chips, can wreak havoc on the walls of most plastic hoses. Polyurethane is the ideal plastic material for use as a flexible material handling hose. The key factor is that polyurethane possesses a high rate of resistance against physical wear. It exhibits a longer lifespan in physically demanding situations. As an added bonus, polyurethane brings a high level of resistance to solvents such as oils and grease.

This wire-reinforced hose is available in most popular internal diameter (ID) sizes ranging from 2” to 12” and is available in standard lengths of 12ft and 25ft. The ends of this flexible duct are plain cut, so the end user has the ability to use clamps of their preference to attach them to their intended outlets. One very distinguishing feature of this polyurethane ducting is its ability to operate in temperatures ranging from -65° F to 225° F, a trait that is lacking in many of its competitors. This general purpose flexible material handling hose is the perfect option for applications such as leaf collection, chemical fume extraction, hull sanding equipment, wood dust collection, and cold/hot air supply.