“Spiral-Lock (Silicone 1P) 550”

“Silico-Fiberglass 550”

“Silico-550 Single Ply”

“Silico-550 Nomex”

“Silico-550 Double Ply”

Screw Clamps

What is Silicone and why Use Silicone in Ductwork?

Silicone is a synthetic compound with low amounts of thermal conductivity, chemical reactivity and toxicity. In its basest definition, silicone is an elastomer like rubber that is blended with carbon, hydrogen, and oxygen. This confers onto a standard red silicone hose a high degree of chemical and thermal resistance. These resistant properties make silicone hoses perfect for a variety of ducting applications that involve the transferring of high temperature air and fumes. Since silicone rubber can handle higher temperatures than other elastomers and since it remains flexible in temperatures of up to +550°F, it makes an ideal high temperature ductwork.

“Spiral-Lock (Silicone 2P) 750”

- Metal strip acts as a wearstrip

- Outstanding resistance to external abrasion

The “Spiral-Lock (Silicone 2P) 750” high-temp flexible hose is made from double-ply silicone coated fiberglass fabric that is mechanically crimped in a continuous process. The silicone coating gives the product great resistance to extreme temperatures, making it great for fume control applications. The fabric on this hose is locked around a coated steel wire by a metal strip that is then formed into a clip. The metal clip on these flex hoses acts as a wear strip and provides outstanding protection against external abrasion. This greatly extends the lifespan of the flex duct hose when used in migratory applications. The double-ply construction of these high-temp flexible hoses provides additional wear resistance.

The silicone coating and double-ply construction of the “Spiral-Lock (Silicone 2P) 750” make this high-temp silicone hose ultra durable. Some of the great benefits of the silicone coating are its resistance to acids, alkalis, solvents, chemicals, and oils. Silicone polymers also offer the best long-term resistance to environmental extremes and is generally unaffected by ultraviolet light or ozone. This silicone hose has a temperature range of -65 degrees to +750 degrees Fahrenheit. Also, the fiberglass material and metal clip wear strip makes these hoses extremely resistant to outside abrasions while maintaining extreme flexibility.

Silicone Rubber’s Advantages Over Other Rubber Products

- Resistance to Weathering: Silicone rubber displays excellent levels of endurance when faced with harsh environmental factors, including UV radiation, extreme temperatures. This quality makes flexible ducting made from silicone to be used in what otherwise would be inhospitable conditions for other types of flex hose.

- Thermal stability: Silicone rubber will retain its shape and flexibility in temperatures of up to +550°F.

- Moisture seals: Silicone rubber is water repellent. A silicone exhaust hose is not meant to convey water, but it will keep moisture from creeping into the body of the hose.

- Highly flexible: Silicone behaves just like other rubber products and can be formed in low durometers for higher flexibility. Silicone flex ducts comparably have a good bend radius and are very functional in tight spaces.

- Ease of decontamination: Silicone rubber can withstand high temperatures therefore sterilizing the product is a possibility.

- Colorable: Silicone rubber can easily be produced in any color. Ironically most silicone ducting is red which is the most popular of the colors it can be produced in.

- Electrical properties: Silicone rubber is an excellent electrical insulator.

- Excellent Hygiene Capabilities — Silicone rubber is non-porous, making bacterial build-up virtually impossible.

“Spiral-Lock (Silicone 1P) 550”

“Silico-550 Double Ply”

“Silico-550 Single Ply”

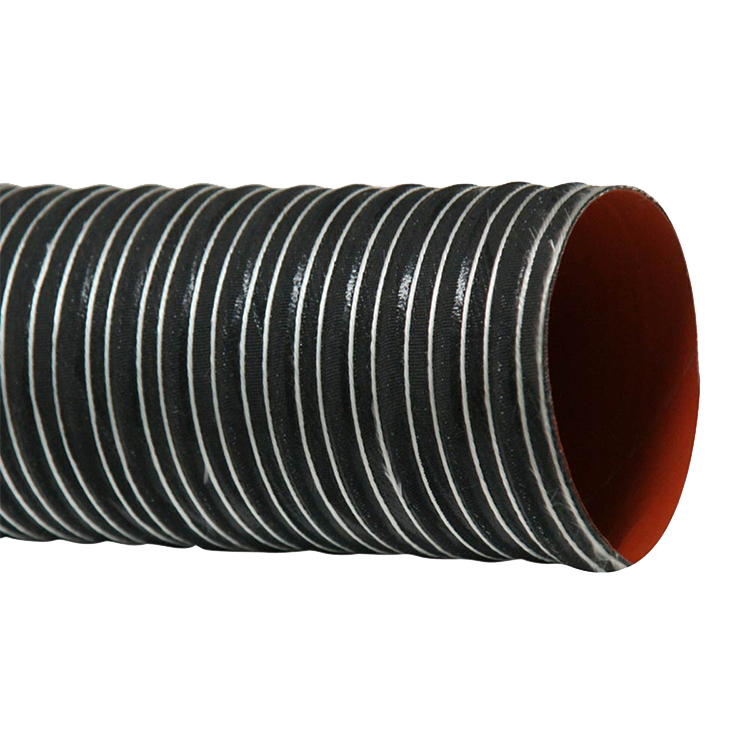

“Spiral-Lock (Silicone 1P) 550”

“Spiral-Lock (Silicone 1P) 550”

-

- Metal clip acts as a wearstrip

- Outstanding resistance to external abrasion

- Extremely flexible

The “Spiral-Lock (Silicone 1P) 550” is a single-ply silicone coated fiberglass fabric high temperature silicone hose that is well suited for fume applications. The silicone coating of this flex hose gives this product useful properties such as flexibility, tear strength, and resistance to extreme temperatures. The hose fabric is locked around a coated steel wire by a metal strip that is formed into a clip. This metal clip acts as a wear-strip that protects the integrity of the “Spiral-Lock (Silicone 1P) 550” and provides excellent protection against external abrasion. Also, the fiberglass fabric makes this an extremely flexible option that is great for when you need a fume exhaust duct in hard to reach areas.

The silicone coating of the “Spiral-Lock (Silicone 1P) 550” makes this flex hose resistant to extreme temperatures. This flexible silicone hose has a working temperature range of -65 degrees to +550 degrees Fahrenheit. In addition to its resistance to high temperatures, the fiberglass material and metal clip wear-strip make the hose extremely resistant to outside abrasions. This high temperature silicone hose is also available with Hypalon and Neoprene coated materials to provide any necessary additional protection.

Do Silicone Hoses Improve Cooling in a Braking System?

Brake cooling duct is a silicone duct hose that is designed to handle high temperatures. We offer a silicone rubber coated fiberglass fabric that is built around a bronze plated steel spring wire helix with an external fiberglass cord support that is ideal for this application. Racing brake pads and rotors have more longevity and perform finest when they are kept within their prime temperature range. Deteriorating rotors and disintegrating brake pads are an indication that the normal temperature ranges have been exceeded. Using silicone brake cooling ducting on your racecar can extend the life of the system and its subparts, while decreasing braking distances.

So, do silicone hoses improve performance and cooling? This is 100% a fact when used in race car brake pads and rotor systems and they help reduce the deterioration of the braking systems. This brake ducting hose is designed to direct air from front-mounted air ducts to spindle ducts for brake cooling. our silicone brake ducting hoses can handle – 65°F to + 550°F, and Intermittently to 600°F.

What is the structure of a silicone hose?

These high temperature silicone hose products are made by combining fiberglass into silicone to provide the ductingwith both flexibility and high-temperature resistance. Our silicone ducting products feature excellent temperature ranges with hoses capable of operating as low as -65°degrees Fahrenheit and up to 550° degrees Fahrenheit. This excellent resistance to heat makes the high temperature silicone tubing ideal for applications like marine and automotive vehicle exhaust systems, which require the transportation of high temperature air and fumes without causing damage to the hose material. In addition, many types of silicone hoses are incredibly strong and feature a double-ply construction that makes it difficult for even the most damaging kinds of abrasives to puncture or tear the hose. Furthermore, its longevity and resilience make silicone ducting ideal for long-term installations and sensitive areas where immediate repair and maintenance may not always be possible.

Screw Clamps

“Silico-550 Nomex”

“Silico-550 Nomex”

- Nomex® material increases flex life & abrasion resistance

- Suited for high temperature air handling applications

- The narrow pitch allows for tight bending radius while maintaining a smooth air flow

- Ideal for applications where constant flexing is involved

- Non-kinking

The “Silico-550 Nomex” High Temperature Hose is a double-ply fabric hose with a silicone coated iron oxide red fiberglass inner-layer and a silicone coated black Nomex® outer layer. Reinforced with a spring steel wire helix, this hose is designed for air and fume control applications. Nomex is a registered trademark for flame-resistant meta-aramid material developed by DuPont. The high temp hoses are non-kinking and ideal for applications where constant flexing is involved. This flexible hose features a narrow pitch that allows for a tight bending radius and smooth airflow.

The “Silico-550 Nomex” high temperature hose is designed to withstand temperatures of both high and low extremes. The high temp hose is suited for temperatures as low as -65 degrees Fahrenheit and as high as +550 degrees Fahrenheit. In addition to extreme temperature tolerance, the air hose is also resistant to many oils & solvents, ozone, water, fungus and alkalis.

How Flexible are Silicone Hoses?

Our high temperature silicone hoses are flexible enough to bend at a 180-degree angle without kinking. For consumers who need constant, consistent airflow through their flexible ductwork, silicone hoses are a godsend. Their anti-kinking properties prevent the hose material from becoming twisted upon itself, or with other lengths of duct. This feature helps to additionally prevent the formation of clots and blockages within your lengths of silicone hose, rendering them fully capable of delivering the constant and reliable airflow that you need. Anti-kinking properties additionally serve to ensure the longevity of your ducts but allow them to remain undamaged and functional.

Does a silicone hose bend? Yes, it does, but the bend radius will depend on the specific duct type. Our silicone hoses are available in a variety of grades, wall thickness and some are available with insulation. The bend radius of each flex duct is available on the flex hose’s specification sheets and does vary as the diameter of the hose changes. The minimum centerline bend radius of smaller diameter ducts is generally less and increases as the diameter of the duct increases. Generally, the more wall thickness silicone hoses have, the less flexible they will be. But the thicker walls (i.e., 2 ply silicone ducting) imply more resistance to abrasion and longer durability. For that reason, it is important to look closely at the specifications of each kind of silicone ducting you choose to use to see if it matches with your specific needs. In addition to different grades and wall thickness, silicone ducts are also available with insulation and custom produced hose end-cuffs.

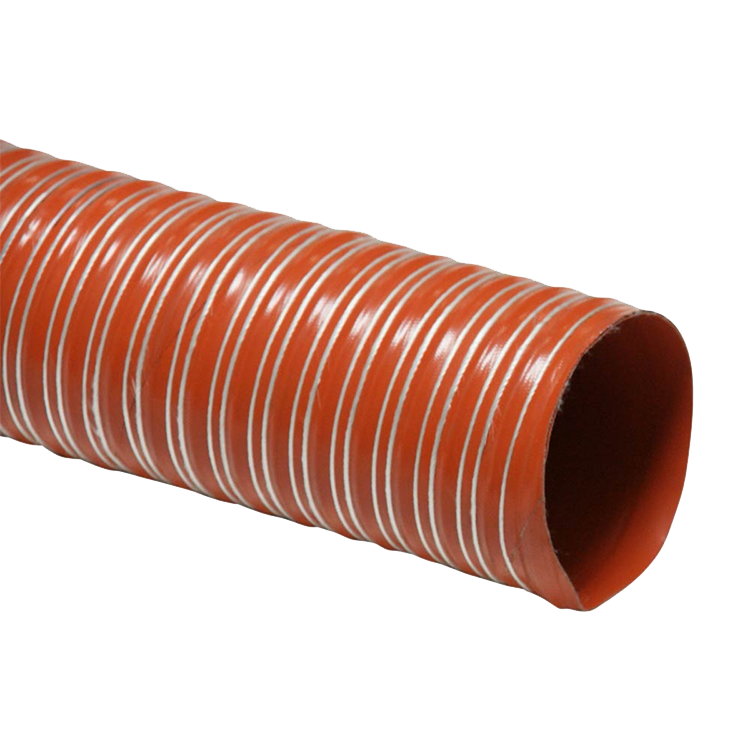

“Silico-Fiberglass 550”

“Silico-Fiberglass 550”

-

- Light weight and flexible

- Available in longer lengths than traditional mandrel built hose

- Resistant to many oils and solvents, ozone, water, fungus, and alkalis

The “Silico-Fiberglass 550” is a lightweight and flexible duct that is suited for air, dust, and fume transportation applications in various industrial settings. This air vent duct is made from single-ply silicone coated fiberglass fabric, which makes the hose both lightweight and flexible. Not only is it flexible, this fiberglass hose is also resistant to elements such as moisture, fungus, and many oils. This hose is also reinforced with a spring steel wire helix that provides good strength and durability. It is recommended that the “Silico-Fiberglass 550” should not be used in applications that require continuous flexing.

The “Silico-Fiberglass 550” flex duct is also tolerant to both high and low temperature extremes. This hi temp hose has a working temperature range of -65 degrees to +550 degrees Fahrenheit. This wide temperature range allows the fume hose to be used in a wide variety of air and fume movement applications. Silicones are inert, synthetic compounds with an assortment of forms and uses. Silicones are polymers that include silicon together with carbon, hydrogen, oxygen, and sometimes other elements.

Answering Some Commonly Asked Questions about Silicone Flex Ducts

- Can silicone hose be shaped?

A silicone duct can flex, therefore a 2-inch diameter flex duct can bend to form an elbow without kinking. This ensures that the flow of air, fumes of gasses in the flex duct is not halted. - Can silicone hoses be stretched?

No, a silicone exhaust hose cannot be stretched, but they can be compressed and will retract back once compressed. Since these ducts are made with a coated fiberglass fabric that is built around a bronze plated steel spring wire helix with an external fiberglass support, they do not behave like a rubber tube. - Are silicone hoses flexible?

Yes, silicone ductwork is very flexible. For example, the Silico-550 Single Ply hose in a 2-inch diameter has a minimum centerline bend radius of 2-inches and a three to one compression ratio. The same flex duct in a 6-inch diameter has a 4.4-inch minimum centerline bend radius and a five to one compression ratio. - How flexible is silicone hose?

All silicone hoses are flexible, but some styles like those built with a coated fiberglass fabric hose construction mechanically crimped in a continuous process are far more flexible. For example the “Spiral-Lock (Silicone) 1P 550” in an 8-inch diameter has a 5.5” center line bend radius and an 8 to 1 compression ratio. This is about as flexible as a flex duct gets. - Does silicone hose bend?

Yes, all styles of silicone ductwork can be bent. But only the “Spiral-Lock” series is recommended for continuous bending and flexing. - Can you heat and bend silicone hoses?

There is no need to heat silicone ducting to bend it, it is flexible by design. We offer 7 versions of this duct and only one is not flexible and it is the “Silico-550 Insulated.” It is not flexible because of the nature of the insulation around the silicone flex hose. - Can you use silicone hose for exhaust?

Yes, silicone ducting is designed to move elevated temperatures, fumes and air. Variations of a silicone exhaust hoseare used in many industrial applications. - Do silicone hoses improve performance?

Yes, wherever there is a need for a high temperature hose, a silicone flexible hose should be considered. Different variations can handle temperatures of up to 550°F and 750°F. These are limits that are not possible for other hoses made from elastomers. Only stainless-steel ducts can compete with type of a temperature range, while stainless steel does not offer the same level of flexibility that silicone ducts do! - Do silicone hoses need special clamps?

No, silicone flex ducts can be clamped down with a worm gear or a screw clamp. However note that a high temp silicone hose should be fastened with a clamp that is also high temperature resistant, like stainless steel. - What is the benefit of silicone hoses?

Silicone duct hoses can handle elevated temperatures of up to 750°F., caustic fumes while offering excellent flexibility and at a very affordable cost. - Are silicone hoses good for a vacuum?

Yes there are silicone ducts can pull a full vacuum like the “Silico-550 Single ply.” This hose in 2.5” diameter and smaller can be used at a maximum negative pressure of 29 inches of mercury.

“Silico-550 Insulated”

“Silico-550 Insulated”

-

- Insulated Industrial dryer hose

- Combines flexibility with minimal heat loss

The “Silico-550 Insulated” hi-temp hose is suited for air handling applications and offers excellent external abrasion and chemical resistance. The Silico-550 Insulated high temp flexible hose consists of two layers. The inner layer consists of double-ply silicone coated woven fiberglass fabric with a spring steel wire helix. The outer layer consists of single-ply neoprene impregnated polyester fabric reinforced with a spring steel wire helix. These two layers are separated by 1-inch fiberglass insulation (R-value is 4). The flexible insulated duct is designed for fume conveyance in industrial air movement applications. In industrial use, this flexible insulated duct allows for minimal heat loss, while maintaining good flexibility and protection from external abrasions and harsh chemicals.

The “Silico-550 Insulated” hi-temp hose has a wide working temperature range. The industrial ducting is designed to withstand temperatures of high and low extremes. The inner layer of the high temp flexible hose has a range of -65 to +550 degrees Fahrenheit (+600 F intermittent). The outer layer of the flexible insulated duct has a range of -40 to +250 degrees Fahrenheit. Not only is the high temp flexible hose able to withstand extreme environments, it is also able to remain flexible without suffering from heat loss.

“Silico-550 Single Ply”

Does Silicone Ducting Crack Over Time?

Some silicone ducts are not made for continuous flexing and if they are used in an application that expects the hose to be flexed in an uninterrupted fashion, the ductwork will crack. If continuous flexing is a requirement for your application, then silicone ducts are not the correct choice. Silicone hoses should only be used when a hose is permanently installed and in these cases the ductwork can be flexed to accommodate the installation. What is commonly called “dry rot” is sometimes a byproduct of this over-flexing of a hose.

Does a Silicone Hose Dry Rot? The answer to this question is yes, the hose will exhibit a cracked or dry-rotted feature, but this is heavily due to it being flexed at improper angles or the hose being moved constantly. A silicone high temp duct is chosen because it can handle high temperatures first and foremost. A silicone exhaust hose can and does flex, but it is not the central reason for its purchase. Our “Spiral-Lock”

“Silico-550 Nomex”

“Silico-550 Single Ply”

“Silico-Fiberglass 550”

Hose Made from a Combination of Silicone & Nomex

When Silicone is combined with Nomex® it gives silicone the added strength and durability required to sustain constant flexing. Nomex® is a flame-resistant meta-aramid material developed in the early 1960s by DuPont®. It is a man-made textile whose ring-like monomers are bonded together into tough, long chains to make immensely strong fibers. Per DuPont® the uses for Nomex® include “staple, yarn and spunlace products include apparel fabrics to protect against flash fire and electric arc exposure; firefighter garments; fabrics and spun yarns for filtration applications; insulation in flame-resistant (FR) thermal protective apparel; rubber reinforcement; and in transportation textiles such as aircraft carpeting .“

The addition of Nomex® to silicone, allows silicone to behave like a fabric, and their combination makes for ductwork that is very flexible and thanks to its fabric-like or canvas structure offers a much better flex-life when compared to plain silicone ducting. The Nomex® material is known for extreme flexibility characteristics as well as its great resistance to high temperature situations making it a great addition to your flexible duct applications that require a hose that will be continuously bent and maneuvered through high temperature working environments. Nomex® is just one material among many that go into silicone hose to make it a truly versatile and high-performance product.

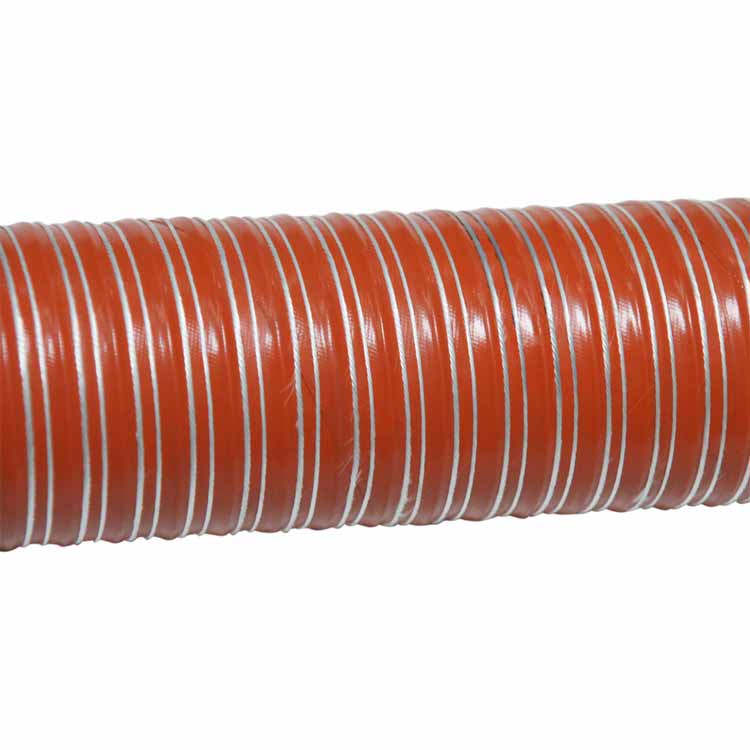

“Silico-550 Double Ply”

-

- Suited for high temperature air handling applications

- Ideal for plastic processing applications

- Non-kinking

The “Silico-550 Double Ply” is a high temperature duct suited for a variety of applications involving hot air and fumes. This air ducting hose consists of double-ply silicone coated fiberglass reinforced with a spring steel wire helix & external filament fiberglass cord. This allows the high temperature duct to be suited for high-temp air handling applications that are ideal for plastic processing operations. The “Silico-550 Double Ply” is also a flexible air hose that has a narrow pitch for flexible venting. This allows the hose to offer a tight bending radius that is non-kinking while maintaining a smooth airflow. While the flexible air hose allows for flexible venting, it is not recommended for continuous flexing.

The “Silico-550 Double Ply” high temperature duct is designed for both high and low temperature extremes. The air hose can operate in temperature lows down to -65 degrees Fahrenheit and can withstand highs up to 550 degrees Fahrenheit (600 F intermittently). In addition, the air ducting hose is also resistant to many oils, solvents, ozone, water, fungus and alkalis. Please consult our Chemical Resistance Guide for specific resistivity of the hose with your media.