“Spiral-Lock (Alum FG) 1050”

Screw Clamps

What Is an Aluminum Flex Duct?

An aluminum flex duct is a lightweight hose made entirely out of aluminum alloy and provides operators with a means to move and ventilate temperature-controlled air and fumes from one point to another. As a material, aluminum is a silver-white metal that is globally known for its practical composition and functionality. From being used in a variety of products such as cans, foils, utensils, mechanical parts, and flexible hoses, aluminum has become a staple in the global economy that is frequently used every day in many places and things. With that in mind, aluminum flex ducts are one of the market’s most popular flexible ducting options due to their high thermal conductivity, which means any heat generated and transferred through an aluminum hose will allow the warmth to pass through the hose efficiently. As a result, aluminum ductwork is ideal for applications involving extreme temperature ventilation. Considering how accessible and practical aluminum is, there are many different types and designs of these flexible ducts that range from ultra-light and compressible models to super thick and heavy units. While the thickness of aluminum ductwork will vary widely based on its application and intended purpose, no matter what kind of flexible aluminum duct you choose, they are undeniably one of the simplest and most reliable semi-rigid ducting options that are budget friendly.

“Aluminum Flex 400”

- Self supporting construction allows for bends to stay in place

- Designed for extreme temperature applications

This flexible ductwork is lightweight, pliable and can easily be bent or manipulated by hand. Our aluminum lightweight ducting is self-supporting, which means the hose will maintain its shape when bent. This important attribute helps in the formation of elbows for easy bending and turning during the installation process. This same self-supporting construction allows any bends to remain in place without the use of additional support materials. One thing to keep in mind is that flexible ductwork should not be exposed to repeated bending and moving. Flexible ducts are not recommended for continuous flexing. Hose connectors are also available for the “Aluminum Flex 400” flexible ducts. Use hose connectors (straight unions) to fit additional pieces of hoses together for extra length.

“Aluminum Flex 400” flexible ducts can be purchased in either 5 or 10 ft lengths. The flexible ductwork is available in several internal diameter sizes including 2, 3, 4, 5, 6, 7, 8, 9, 10, and 12 inches with internal diameter tolerances of -0.00 to +0.250 inch. These lightweight ducting can be utilized in a variety of applications that includes removal of the following: chemical fumes, circuit board cooling, exhaust systems, HVAC, oil mist removal, pollution control and ventilation. If you have any questions or need further assistance with these hi-temp hoses, please do not hesitate to contact one of our ducting experts today.

Why Use Aluminum Ducting?

Here are the top 14 reasons to use Aluminum Ducting.

1. They can handle temperatures of up to 400℉, though some varieties can only handle up to 284℉.

2. Aluminum hoses are flexible. Aluminum is a malleable material. This makes this metal a competitor for flexible vinyl and urethane hoses.

3. Aluminum Ducts are semi-rigid and will maintain shape when flexed. Need a hose for a welding application that can maintain its shape as the source of weld fumes move. This semi-rigid duct should be considered.

4. Aluminum is extremely lightweight and has a high strength-to-weight ratio.

5. It has excellent puncture resistance. Where vinyl, silicone, urethane, or rubber ducts can be punctured, aluminum has extremely good puncture resistance.

6. Aluminum does not rust! (Rust is a type of corrosion referring specifically to the oxidation of iron or steel caused by interaction with water or moisture)

7. Aluminum offers excellent resistance to corrosion. (Corrosion, generally, is a broad reference to the wearing away of metal caused by a chemical reaction.)

8. It is also extremely hygienic since it does not react with most common chemicals.

9. Aluminum is easily recyclable.

“Aluminum Flex 280 – Compressible”

“Spiral-Lock (Alum FG) 1050”

What Is a Semi-Rigid Aluminum Duct?

A semi-rigid duct is a type of ductwork that stays put when flexed and that combines the flexibility of a flexible hose and the durability of a rigid duct into one singular unit. These flexible ducts are best suited for residential and commercial applications requiring high-temperature air movement and ventilation that doesn’t take up too much space. For instance, industrial dryer and range hood ducts need semi-rigid flexible hoses to appropriately transfer hot air from its generated source to the outside to prevent hot air from accumulating inside machines and buildings. These flexible hoses should not be confused with rigid or flexible ductwork because there is a significant difference between them. Rigid aluminum ducts, for instance, are designed to be a permanent ducting solution for extensive industrial facilities that need to move large volumes of air daily and rapidly. Meanwhile, semi-rigid aluminum ducts and flexible hoses are a variation of the rigid ducts but offer flexibility which helps in the installation process when a hose is expected to turn and twist its way to its destination.

Semi-rigid ducts like our aluminum ducts are often made thinner than rigid ducts. Since flexibility in a hose requires a thinner wall, semi-rigid ducts are made thinner to be more flexible. Another significant difference between the hoses is their installation process; the installation of a hard rigid duct is considerably complicated and time-consuming due to its large, heavy, non-flexible build. While flexible hoses and semi-rigid ducts are easier to install than their heavy counterparts, a semi-rigid aluminum duct can maintain its shape and form without additional support of materials and accessories when installed. This feature allows operators to shape and contort these hoses into whatever shape and direction they desire, making them significantly easier to install than their rigid and flexible counterparts. As a result, a semi-rigid aluminum duct pipe is ideal to install in residential and commercial properties with limited architectural space.

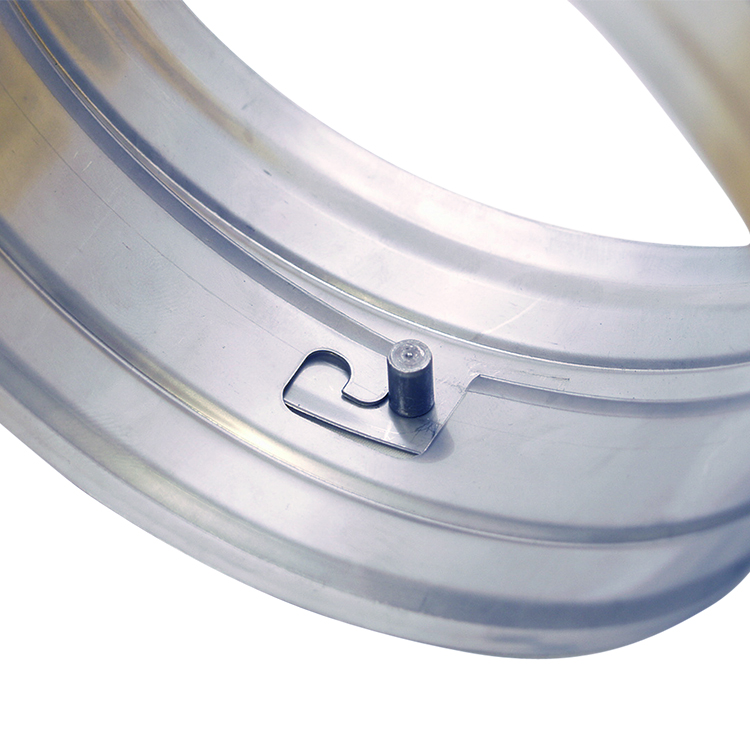

“J-Lock Connectors”

- Quickest way to connect and disconnect hoses

- Designed with a raised lip to prevent hose clamp from slipping off

- Available in sizes 4″ to 20″

J-Locks connectors are a flexible duct connector that can quickly connect or disconnect two hoses of the same ID size. J-Lock Connectors are ideal for migratory applications that may require the assembly of longer hose lengths into one continuous coil. This type of hose connection allows shorter lengths of hose to be assembled into longer runs quickly and easily. In addition, these hose connectors are affordable duct accessories that not only are ultra-durable but also reduce overall assembly costs. Rather than investing in longer continuous runs of custom-made hose, operators can purchase standard 25ft. lengths and connect them using the J-Lock connectors to achieve desired hose lengths.

Unlike other hose connectors, this duct connector allows the operator to detach two hoses without the painstaking process of un-clamping the hose from the connector. As specified by its name, the “J-Lock Connectors” have a lock feature in the shape of the letter “J”; this feature allows the connection of a male end and female end with a simple twist. This hose connection is also designed with a raised lip to prevent the hose clamp from slipping off when clamped over the flexible duct. “J-lock” hose connectors are easy to use tools that reduce downtime and improve onsite installation performance.

“Bridge Clamps”

“Aluminum Connectors”

“Aluminum Flex 280 – Compressible”

-

- Designed for extreme temperature applications

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The Aluminum Flex 280 – Compressible comes prefabricated in a variety of different inside diameter (I.D.) sizes: 3″, 4″, 5″, 6″, 8″, 10″, and 12″. The walls of this flexible metal tubing are 0.1 to 0.11 mm. thick, and it has an I.D. tolerance of 0 to 0.1 inch. Its end finishes are plain cut, and it comes in a classic, metallic-silver colorway. This flexible metal hose is also semi-rigid, which means that, once you bend it into a certain position, it will stay that way without any added support. Of course, you can bend it again to reform the duct into a different position. In sum, it’s likely that you will not need to use any accessories such as elbows to fit your Aluminum Flex 280 – Compressible into looping or bent positions.

This flexible metal duct is designed with air and fume ventilation applications in mind, thus making it well-suited for a variety of residential, commercial, and industrial applications—especially those that intend to transport high-temperature matter. Wood stoves, for instance, need to properly ventilate hot smoke from the wood they burn. The Aluminum Flex 280 – Compressible is a natural fit for these kinds of applications—especially since, oftentimes, a wood stove’s exhaust duct must navigate a circuitous pathway to reach the destination where it expels the stove’s fumes. Other common uses for this metal flex-duct include chemical fume ventilation, circuit board cooling, and air conditioner ducting, among other things.

Can You Cut Aluminum Ducting?

It is possible to cut aluminum ducting with tools that cut through aluminum; however, be forewarned that a cut aluminum hose will not be in a decent visual shape when the cutting is complete. If aesthetics are important then cutting an aluminum duct is not a good idea. We stock a compressible aluminum duct that can be compressed rather than cut. This will save the end-user time and money. The “Aluminum Flex 280 – Compressible” is an aluminum duct that extends from 0.8 meters to 3 meters, a ratio of 3.7 to 1. When the hose ships, it is in a 32-inch length, but it can stretch into roughly 118-inches when fully extended. You can compress this product rather than cut the duct to get quicker and more effective results. If cutting an aluminum duct is a must, then you can cut a duct using tin snips, or straight-cutting compound snips. Wood-cutting saws with carbide-tipped blades do cut most aluminum, but these may not be a gentle way to reduce the size of an aluminum duct. Many fabrication shops shy away from aluminum because it is hard to cut, form or weld.

“Spiral-Lock (Alum FG) 1050”

-

- Metal strip acts as a wearstrip

- Outstanding resistance to external abrasion

- Extremely flexible and easily compressible

The “Spiral-Lock (Alum FG) 1050” high temperature hose operates at extremely high and low temperatures. This fiberglass hose material has a temperature range of -65 degrees to +1050 degrees Fahrenheit and can intermittently withstand a high temperature of +1250 degrees Fahrenheit. The fiberglass hose material also makes the duct resistant to outside abrasions.

The “Spiral-Lock (Alum FG) 1050” high temperature hoses are available in standard lengths of 25 feet and come with plain cut ends. This flexible hose is available in internal diameter sizes ranging from 3 to 18 inches. This hose is easily compressible which allows for quick and convenient storage. The hose has up to a 10 to 1 compression ratio, which means a 25 ft length of the flexible hose will compress down to just over 2.5 feet! A polyurethane clip would also be available, which would add even more protection to the helix and other equipment that is not attached to the hose. While this hose is ideal for automotive exhaust, it has other applications such as jet fuel vapor venting, chemical plant venting, tractor pull exhaust systems, welding, and fume exhaust removal. If you have any questions, feel free to contact one of our ducting specialists today!

Can you use a flexible aluminum duct for HVAC?

Semi-rigid aluminum flex hoses are used in HVAC systems because of their durable nature. Semi-rigid aluminum ducts are used in HVAC systems because of their excellent resistance to common chemicals and weathering. HVAC systems move ambient air in homes and commercial spaces. HVAC systems are not meant to move corrosive chemicals or caustic fumes. Therefore, aluminum is a great choice here. Aluminum is widely used as a material in automobiles, aviation, household appliances, containers, and electronic devices because it will do well in environments that do see corrosives.

However, aluminum gets easily affected in the presence of corrosive acids which should not be present in systems that condition air for human consumption. Most building materials are eventually degraded by weathering, corrosion, rot and decay. Aluminum’s natural ability to resist these stimuli better than many materials is one of its most widely appreciated features. In HVAC systems aluminum is now a viable top choice wherever durability combined with minimal upkeep are chief concerns. Aluminum longevity is partly due to its excellent abrasion resistance. When scratched, this metal is not any less durable than unscratched metal. Unlike vinyl and rubber hoses that eventually degrade from exterior abrasion and weathering, aluminum is a long-lasting hose. And its heat resistance is another factor in its longevity, which can be up to 400 degrees Fahrenheit, making an aluminum duct a first choice when hose may be exposed to high temperatures.

“Stainless Steel Connectors”

“Bridge Clamps”

-

- Stainless steel band & welded stainless steel bridge with carbon steel screw

- Fits over the helix creating a leak proof seal

- Available in clockwise & counter-clockwise

In addition to our hose and duct products, Ducting.com offers essential hose and duct accessories intended to increase your efficiency and productivity. While selecting the appropriate flex hoses for your application, it is also imperative to consider which accessories are required for the job, for instance, the types of hose clamps needed. One type of clamps we offer are the “Bridge Clamps” which are used to secure hoses onto a pipe or connector. Bridge clamps are used to secure hoses at connection points, and since the flat band clamps snugly around the material between the raised helix of the hose, a more secure connection is made possible.

Contrary to aluminum, stainless steel is an important alloy with many beneficial usages because of its excellent characteristics. Stainless steel is embedded with a significant amount of chromium, which then creates a passive and thin layer of chromium oxide that acts as a barrier to prevent damages to its surface. This is how stainless steel retains its luster and attractive appearance over a long period of time.

“Screw Clamps”

What Is the Heat Rating of an Aluminum Flex Duct?

Aluminum ducts can handle high temperatures up to 280 or 400 degrees depending on the type of duct. For example, our “Aluminum Flex 280” can withstand a temperature range that goes as high as 280 degrees Fahrenheit. Instead, operators would need to use a flexible duct specifically designed to retain scorching hot heat levels, such as the “Aluminum Flex 400”. This flexible aluminum hose can withstand temperatures as high as 400 degrees Fahrenheit due to its four-ply finished seam that is folded flat and crimped for tightness and strength. While the “Aluminum Flex 400” is very similar regarding functionality and features to the “Aluminum Flex 280”, the “Aluminum Flex 400” is a far more durable aluminum hose option for any industrial heat ducting application.

When comparing stainless steel vs aluminum, stainless steel has much better resistance to heat with a melting point of 2,500 degrees Fahrenheit , while aluminum becomes very soft around 400 degrees Fahrenheit with a melting point of 1,220 degrees Fahrenheit. However, aluminum has the advantage over steel in cold temperatures. As the temperature decreases, the tensile strength of aluminum increases, while steel becomes brittle in low temperatures.

“Aluminum Flex 280 – Compressible”

“Spiral-Lock (Alum FG) 1050”

Is PVC Ducting Better Than Aluminum?

When it comes to determining the best ductwork for your application, PVC and aluminum rival each other in availability, practicality, and affordability. While utilizing PVC ducting is a cost-effective means for ventilation, exhausting, and light material handling collecting, vinyl ducts are not suited for extreme temperature ventilation applications such as dryer ducting and industrial fume exhaust. A flexible ducts made entirely out of PVC can handle temperature up to 160 degrees Fahrenheit while aluminum ducts can handle up to 400 degrees Fahrenheit. Aluminum ducts made entirely from aluminum alloys showcase higher resilience towards extreme heat and have a higher heat threshold before the material breaks down and loses strength.

PVC ducting is more flexible and far lighter in weight. This makes a vinyl duct an easy product to fit in tight corners or coil up and put away when seasonal usage is required. By comparison, aluminum ducts are heavier and a far more cumbersome product to flex. As noted earlier, unlike vinyl or PVC, aluminum ducts are semi-rigid and maintain their shape when flexed.

“Aluminum Connectors”

-

- Designed with a raised lip to prevent hose clamp from slipping off

- Available in sizes 1.5″ to 24″

- Light and easy to handle

“Aluminum Connectors” are a straight union hose connector that a duct gets clamped down onto without the need for special tools. Aluminum is a relatively soft, durable, lightweight, ductile and malleable metal that makes for an easy to handle product. Our aluminum hose connections have a typical aluminum appearance of dull gray, are nonmagnetic, do not easily ignite, and handle above ambient temperatures. Furthermore, it is one-third the density and rigidity of steel, ideal for applications that require more flexibility. Aluminum duct fittings make sense from the standpoint of cost and longevity.

Aluminum hose connections are used to connect or extend two hoses of the same ID size together. Once connected, the hoses are able to provide the necessary flow over longer sections. The hose connector is designed with a raised lip to prevent the hose clamp from slipping off. These are very affordable duct fittings, which makes adding hose connections a less costly venture when compared to buying longer lengths of custom-made hose. Due to the availability of sizes (1.5″ to 24″ID), these connectors can be used for a number of applications. When compared to stainless steel connectors, the aluminum connectors are more affordable, lighter and a better buy for general air ventilation applications.