“Silico-Fiberglass 550”

“Silico-550 Single Ply”

“Silico-550 Nomex”

“Silico-550 Double Ply”

“Acrylic Flex 325 Air Handler”

“Acrylic Flex 325”

Screw Clamps

What Is a Dryer Duct?

A dryer duct is a type of flexible hose used to vent hot air, moisture, and lint from a dryer machine to the outside of a building. Drying is defined as the vaporization of absorbed moisture from wet materials. The basic process revolves around transferring heat generated from a source, such as metal coils or natural gas, to the material, which causes the absorbed water to vaporize. The evaporated water is transferred and carried by the surrounding air or inert gas through a flexible duct and vented outside. Removing all the excess heat and moisture from the machine prevents the growth of bacteria on the dried materials and protects and maintains the quality of the machinery and materials. There are two installation methods when installing flexible ducting for dryers: outdoor and indoor. An outdoor dryer duct is a flexible duct connected to your dryer, and the hose is lined and attached to the exterior of the wall, expelling hot air, moisture, and lint outdoors. On the other hand, an indoor dryer duct is installed inside the wall throughout a building and has a filter to trap lint and moisture to prevent the two from getting stuck inside and accumulating bacteria such as mold.

No matter what kind of installation method you choose for your dryer, cleaning out the lint filters is important because lint is highly flammable and can cause more damage than you might think. If the dryer duct is clogged full of lint, it can entrap hot air into the machine and part of the ductwork, and if the inner temperature reaches a critical high, the heat could ignite the lint and everything within. According to the NFPA (National Fire Protection Association), dryers cause an average of 16,000 fires yearly, and lint-related fires are the leading cause. Considering the number of accidents for residential and commercial dryers, it is incredibly vital for industrial dryers to expel heated air through a flexible dryer vent because they operate at a much higher capacity and heat level than their counterparts.

Residential vs. Commercial Dryers

When it comes to understanding the differences between residential and commercial dryers, it mainly falls into their operating capabilities. Whether it is a residential or commercial dryer, both types use a heating element such as metal coils or natural gas to generate heat and dry a load of clothes during a drying cycle. The most noticeable differences are in their size, capacity, and functional efficiency. Commercial dryers have a larger drying cylinder size, higher airflow, and higher BTU ratings that can significantly reduce drying time and increase the efficiency of the laundry process. Residential dryer units are designed for individual usage, and as a result, they are meant for less frequent usage than their commercial counterparts. However, while commercial dryers perform at a more optimal rate, they are larger and more durable than residential models and require more space to be placed and installed. With that in mind, commercial dryers would require larger-sized flexible ducts to accommodate their channel size. Depending on your application, commercial dryers are better suited to handle larger quantities at a time. However, it comes at the cost of space and additional charges.

“Aluminum Flex 400”

- Designed for extreme temperature applications

- Self supporting construction allows for bends to stay in place

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The “Aluminum Flex 400” hi-temp hoses are great for funneling above ambient industrial air and fume. The metallic silver lightweight hose is constructed from a single-ply, helically corrugated aluminum alloy. The walls of the flexible ducts are constructed using a durable four-ply finished seam that has been folded flat and crimped for binding and strength. With a working temperature range of -100 to + 400 degrees Fahrenheit, these aluminum ducts are built to withstand extreme temperature applications. They are made to resist fatigue, weathering, and most corrosive fumes and chemicals. Aluminum flexible ducts are far more durable than their elastomeric counterparts, even when corrosive fumes are present.This flexible ductwork is lightweight, pliable and can easily be bent or manipulated by hand. Our aluminum lightweight ducting is self-supporting, which means the hose will maintain its shape when bent. This important attribute helps in the formation of elbows for easy bending and turning during the installation process. This same self-supporting construction allows any bends to remain in place without the use of additional support materials. One thing to keep in mind is that flexible ductwork should not be exposed to repeated bending and moving. Flexible ducts are not recommended for continuous flexing. Hose connectors are also available for the “Aluminum Flex 400” flexible ducts. Use hose connectors (straight unions) to fit additional pieces of hoses together for extra length.

“Silico-550 Single Ply”

What Is an Industrial Dryer?

An industrial dryer is a high-powered device that removes moisture from products, materials, and mixtures. They are large, durable industrial machinery capable of drying high volumes of products efficiently with precision and control. These machines are often lumped together with industrial-grade clothes dryers, and while both machines incorporate the same level of power, they are used in different applications. Industrial dryers are used in industries such as food production, pharmaceuticals, agriculture, textiles, metal fabrication, and automotive manufacturing. It is important to note that all these industries incorporate different variations of industrial dryers to cater to their specific needs and products, and the main differences between all the various types are based on the mechanism used to remove moisture, size, and drying capacities. However, these industrial dryers require hot air to be vented through sturdy and reliable ductwork.

“Silico-Fiberglass 550”

“Silico-550 Double Ply”

“Silico-550 Nomex”

“Silico-550 Single Ply”

“Silico-Fiberglass 550”

Which Is Better: Flexible or Rigid Dryer Ducts?

Flexible ducts are widely used as a dryer duct vent due to their accessibility, range of options, and easy-to-install nature. For most residential and commercial applications, a flexible hose is more than enough to handle the daily rigors of dryer ducting. While rigid ducting is made from sturdier materials such as stainless and galvanized steel, it is mainly designed to handle long-term and heavy-duty ducting within the industrial sector. With that in mind, rigid ductwork is considerably heavier than flexible ducts and requires a costly and time-consuming installation process. As a result, rigid ductwork is mainly geared towards those looking for a permanent solution for their dryer ducting needs. However, in most residential and commercial applications, the initial costs of installing rigid ducting outweigh its benefits because, in addition to a meticulous installation process, it requires the architecture of a building to be strong enough to support its weight. Most industrial machinery and applications choose flexible ducts over rigid ductwork for their flexibility and practicality. A dryer flex duct is meant to be a semi-permanent solution to a semi-permanent machine; as such, if the condition of a flexible duct has deteriorated to the point of no return, it can be easily replaced within a day. Despite some timely upkeep, flex hoses are a tremendous, cost-effective alternative to hard, rigid ductwork for any dryer venting needs.

“Silico-550 Insulated”

- Insulated industrial dryer hose

- Combines flexibility with minimal heat loss

- Suited for air handling applications at low positive and low negative pressures

The “Silico-550 Insulated” hi-temp hose is suited for air handling applications and offers excellent external abrasion and chemical resistance. The Silico-550 Insulated high temp flexible hose consists of two layers. The inner layer consists of double-ply, silicone coated, woven fiberglass fabric with a spring steel wire helix. The outer layer consists of single-ply neoprene impregnated polyester fabric reinforced with a spring steel wire helix. These two layers are separated by 1-inch fiberglass insulation (R-value is 4). The flexible insulated duct is designed for fume conveyance in industrial air movement applications. In industrial use, this flexible insulated duct allows for minimal heat loss, while maintaining good flexibility and protection from external abrasions and harsh chemicals.

The “Silico-550 Insulated” hi-temp hose has a wide working temperature range. The industrial ducting is designed to withstand temperatures of high and low extremes. The inner layer of the high temp flexible hose has a range of -65 to +550 degrees Fahrenheit (+600 F intermittent). The outer layer of the flexible insulated duct has a range of -40 to +250 degrees Fahrenheit. Not only is the high temp flexible hose able to withstand extreme environments, it is also able to remain flexible without suffering from heat loss.

“Aluminum Flex 400”

What Is the Best Duct to Use for a Dryer Vent?

Aluminum flex ducts are among the most popular and widely used ducts for dryer vents due to their lightweight, cost-effective design. Made from single-ply aluminum and a corrugated aluminum alloy hose wall, aluminum flex ducts are readily available in a large assortment of inside diameter (I.D.) sizes and lengths. Aluminum hoses are ideal because of their resistance to metal fatigue, weathering, and extreme temperatures, making them perfect for residential and commercial dryer ducts. While aluminum hoses are not recommended for continuous flexing and stretching, their self-supporting construction allows them to be easily bent and formed during installation. For example, the “Aluminum Flex 280” is an excellent aluminum dryer duct that can be used for dryer ventilation due to its sturdy compressible design and natural resistance to high temperatures. The “Aluminum Flex 280” is classified as a semi-rigid duct, which means it offers both the flexibility and durability found in flexible hoses and rigid ducting. By using an aluminum dryer duct, you are using one of the most reliable and common types of dryer ventilation that can withstand the test of time, and should you ever require a new one for whatever reason, they are readily available wherever you go.

“Aluminum Flex 280 – Compressible”

- Light weight & hand bendable allowing for elbows and turns to be formed easily during installation

- Self-supporting construction allows for bends to stay in place

- Designed for extreme temperature applications

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The Aluminum Flex 280 – Compressible is an aluminum duct that extends from 0.8 meters to 3 meters, a ratio of 1 to 3.7! This metal duct has a single-ply, helically corrugated structure—making it a very durable, as well as lightweight product. These helical corrugations are one part of the reason for why this duct can extend to over three times its compressed length!

This flexible metal duct is designed with air and fume ventilation applications in mind, thus making it well-suited for a variety of residential, commercial, and industrial applications—especially those that intend to transport high-temperature matter. Wood stoves, for instance, need to properly ventilate hot smoke from the wood they burn. The Aluminum Flex 280 – Compressible is a natural fit for these kinds of applications—especially since, oftentimes, a wood stove’s exhaust duct must navigate a circuitous pathway to reach the destination where it expels the stove’s fumes. Other common uses for this metal flex-duct include chemical fume ventilation, circuit board cooling, and air conditioner ducting, among other things.

“HVAC Ventilation-Flex”

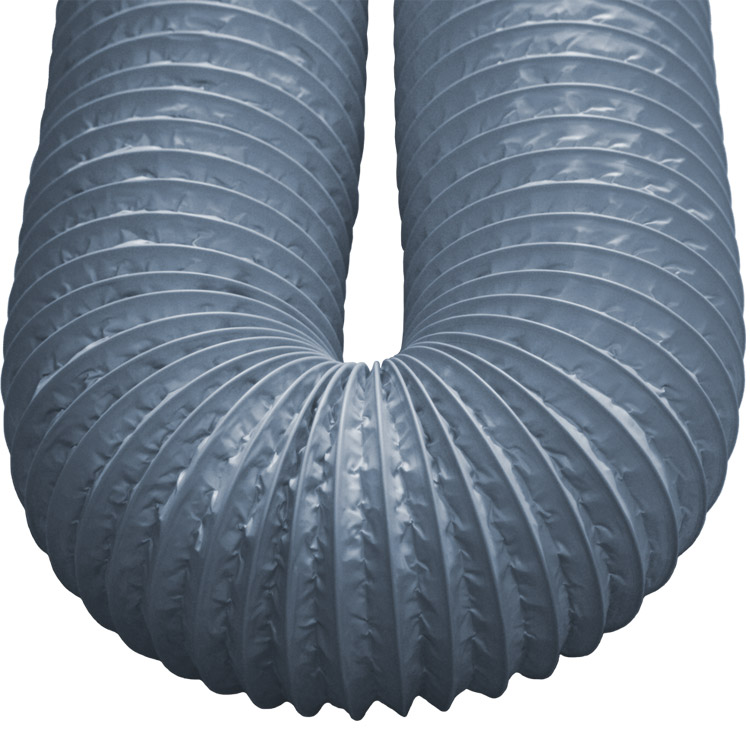

Can You Use an HVAC Duct for a Dryer Vent?

While HVAC ducts are known for transferring temperature-controlled air throughout a building’s ductwork, they can also be utilized as a flexible dryer vent. However, it is crucial to note that HVAC ducts must match the size specifications and length to fit onto a dryer. These flex ducts also need to be made from materials that can handle the daily rigors of dryer ductwork. For instance, the “HVAC Ventilation Flex” hose is a fantastic example of an HVAC hose that can be utilized for dryer ducting. The “HVAC Ventilation Flex” hose is a high-quality and affordable flexible hose that is made from a combination of materials, including PVC, aluminum, and a layer of PET film. As a result of this design, the flexible hose provides excellent air movement and a high level of noise and heat insulation, all of which are critical when choosing a dryer duct. The “HVAC Ventilation Flex” hose can withstand a temperature range of -20 to 160 degrees Fahrenheit, and the flexible body of the dryer hose can be shaped and installed into various shapes and tight spaces, which makes it ideal for buildings with limited architectural space. With all of these factors in mind, the “HVAC Ventilation Flex” hose is a great example of an HVAC hose used as an effective alternative to your dryer ducting needs.

“HVAC Ventilation-Flex”

- Ultra affordable flexible duct

- Alum 0.0065 mm in thickness

- PET 0.014 mm in thickness

- Gray PVC 0.010 mm in thickness

The HVAC Ventilation Flex is a high-quality and affordable ducting hose which provides an excellent option for customers looking for air movement solutions. These durable HVAC ducts are designed specifically for the transfer of air, and they excel in applications including air conditioning duct work. The HVAC Ventilation Flex is a versatile and flexible HVAC duct which can be used in a range of different settings, from residential use to industrial applications.

With its dual layer PVC and aluminum body, the HVAC Ventilation Flex has a great range of features. To start with, it provides a high level of noise and heat insulation. This insulation allows the hose to remain effective in extreme hot and cold temperatures, with a working range from -20 degrees to 160 degrees Fahrenheit. This means that the ducting can support the movement of air within that temperature range. This makes it effective as an air conditioning duct or a hot air vent, among other applications. The body of this ducting hose is also extremely flexible, allowing it to be contorted and manipulated into various shapes and tight spaces as required by a project or application.

“Silico-550 Double Ply”

“Silico-550 Single Ply”

“Silico-Fiberglass 550”

“Silico-550 Nomex”

Are Silicone Flex Hoses Good for Dryers?

Due to their strength and durability, silicone-based flex hoses are suitable alternatives for industrial dryers and are considered the most relied-on choice. As a material, silicone is a non-organic synthetic polymer that will not deteriorate as quickly when compared to organic elastomers. Depending on the application, a silicone-based dryer flex hose can last very long, and the material can be altered to suit any specific application. As such, silicone flex hoses come in different types and features that cater to specific applications. From an insulated design to a flame-resistant feature, silicone flex hoses are best suited for air-handling applications in harsh conditions. Silicone flex hoses can withstand an extreme temperature range from -65 to +500 degrees Fahrenheit, making them perfect for industrial dryers venting scorching hot air. Silicone hoses are also resistant to many oils, solvents, ozone, water, fungus, and alkalis and feature a non-kinking design that assures hot air is properly ventilated from industrial dryers. As industrial dryers require a flexible hose to vent out hot, damp air, they need a flexible hose that can handle the rigors of their daily applications.

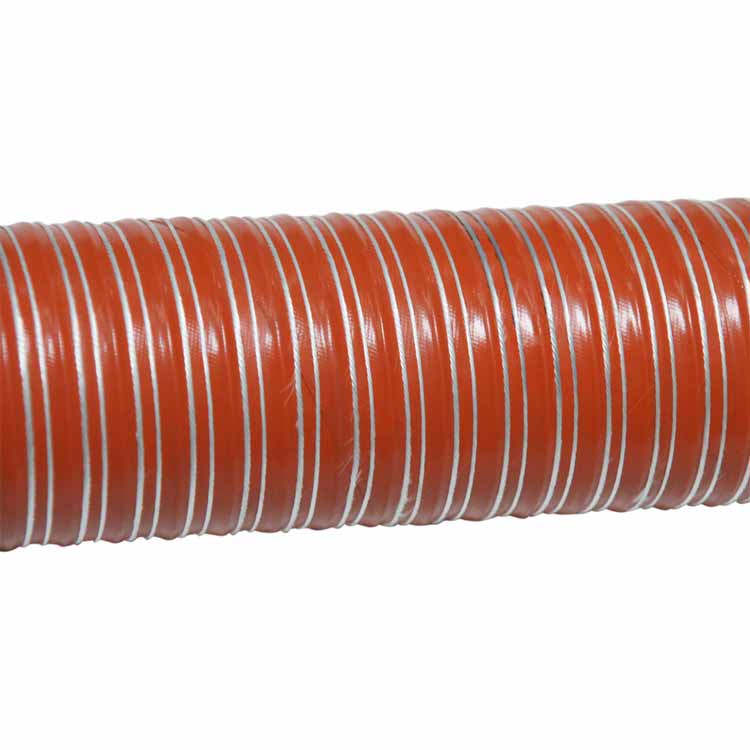

“Silico-550 Double Ply”

- Suited for high temperature air handling applications

- Ideal for plastic processing applications

- Non-kinking

- Resistant to many oils and solvents, ozone, water, fungus, and alkalis

The “Silico-550 Double Ply” is a high temperature duct suited for a variety of applications involving hot air and fumes. This air ducting hose consists of double-ply silicone coated fiberglass reinforced with a spring steel wire helix & external filament fiberglass cord. This allows the high temperature duct to be suited for high-temp air handling applications that are ideal for plastic processing operations. The “Silico-550 Double Ply” is also a flexible air hose that has a narrow pitch for flexible venting. This allows the hose to offer a tight bending radius that is non-kinking while maintaining a smooth airflow. While the flexible air hose allows for flexible venting, it is not recommended for continuous flexing.

The “Silico-550 Double Ply” high temperature duct is designed for both high and low temperature extremes. The air hose can operate in temperature lows down to -65 degrees Fahrenheit and can withstand highs up to 550 degrees Fahrenheit (600 F intermittently). In addition, the air ducting hose is also resistant to many oils, solvents, ozone, water, fungus and alkalis. Please consult our Chemical Resistance Guide for specific resistivity of the hose with your media.

Should You Use Plastic Ducts for Dryers?

While plastic ducts are a cost-effective alternative for those looking for an affordable dryer flex duct, due to plastic’s material composition of plastic, the hose would slowly deteriorate and could melt from the ventilated heat. However, plastic coatings on poly-fabric flex hoses are a different story. Flexible hoses such as the “Acrylic Flex 325” are acrylic-coated ducts that are designed to handle industrial ventilation applications. The lightweight dryer hose is capable of handling temperatures between -20 to +325 degrees Fahrenheit and features a flame-retardant feature that follows the U.L. 94V-O fire standard. While acrylic flex ducts are not as sturdy when compared to other dryer ducts, such as silicone flex hoses, acrylic flex ducts are meant to serve as a cost-effective alternative to handle lower temperature applications. With that in mind, acrylic flex ducts are an excellent choice for residential and commercial dryers to take exhaust overhead.

“Acrylic Flex 325”

- Ideal for air & fume handling applications with temperatures up to 325 Fahrenheit

- Excellent choice for overhead vehicle exhaust systems

The “Acrylic Flex 325” high temperature hose is an extremely versatile, high temperature, acrylic flexible duct intended for use in a variety of industrial applications. This black flexible hose is constructed from single-ply acrylic coated polyester fabric. The durable material is reinforced with a spring steel wire helix for added strength, reinforcement and flexibility, allowing it to be easily utilized in a variety of settings. This hose is an excellent choice for overhead vehicle exhaust systems. The most effective method of removing vehicle exhaust fumes in garages is capturing it at the source. This abrasion resistant flexible hose makes it a durable option in this arena.

The “Acrylic Flex 325” flexible duct is also suited for transporting air, dust, and fumes. The reinforced acrylic fabric has a wide temperature range. This high temperature hose has a working temperature range from -20 to +325 degrees Fahrenheit, which makes transporting heated air and fumes up to 325 degrees Fahrenheit easier and safer. This lightweight and flexible high temperature ducting comes in standard lengths of 25 feet for use in large or small scale projects. It is listed as a UL 94 V-0 flame retardant product. For any material to be considered UL 94 V-0, the material that is exposed to a vertical flame (which is removed after 10 seconds) must stop burning within 10 seconds and do so without flaming droplets. The hose is available with an external wear-strip. This added level of protection helps to protect the flexible hose from being worn or damaged on the outside of the product.