“Urethane Flex Medium-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Urethane Flex Heavy-Duty”

“Thermoplastic Flex Medium-Duty”

“Urethane Flex Static Dissipative”

“Urethane Flex Self Extinguishing”

“PVC Flexduct Medium-Duty”

“Urethane Flex Extra Heavy-Duty”

“Thermoplastic Flex White”

“PVC Flexduct Heavy-Duty”

“Thermoplastic Flex Super Reinforced”

“PE Flex Translucent”

Screw Clamps

What Is a Suction Hose?

A suction hose is a specific type of flexible hose designed to suck up materials such as dirt, trash, dust, debris, and raw materials. Suction is created when a pressure drop between two confined areas creates differential air pressure. The air being removed from an area creates a pressure drop and vacuum, resulting in the creation of suction. Depending on your application, there are several different equipment designed to create a vacuum and a suction. Residential vacuum cleaners, for instance, utilize an electric-powered fan to create a pressure drop and a partial vacuum. These vacuum systems use flexible hoses and ductwork to facilitate the transfer of materials from their source to a collection area, and depending on the type of material and the quantity, the inside diameter (I.D.) size will vary. For example, smaller inside diameter (I.D.) sized hoses require more pressure to take account of the restricting amount of space to transfer materials. Compared to ducts with larger-sized inside diameters (I.D.), smaller diameter ducting need less pressure to transfer materials because there is less resistance and less space to create suction. No matter what kind of vacuum equipment you use, the flexible hoses that are attached must be designed to handle the negative pressure generated from the equipment, or else, you risk the flex hose caving in on itself and rendering it inoperable and generally impractical.

Defining Negative Pressure

Negative pressure is defined as the condition where air pressure is significantly lower in one area in comparison to another. In relation to suction hoses, negative pressure needs to be generated by a machine to create a partial vacuum, creating a gap of pressure that extracts air and materials to fill this vacuum. Every vacuum unit utilizes fans and motors to create negative pressure, and the partial vacuum size it creates depends entirely on the overall power and capabilities of the vacuum unit. In order for operators to determine what sized flexible duct they require to handle their equipment’s level of negative pressure; they have to look at the hose’s ability to pull negative air which is measured in inches of mercury. This measurement, Inches of Mercury (IN./HG), is a unit of capacity used to determine the atmospheric pressure level of a duct, pipe, or flexible hose. If a flexible duct has a high inch of mercury level, it means the suction hose can withstand high atmospheric pressure. If a suction hose has a low inch of mercury level, it means the hose is not recommended to handle the high atmospheric pressure generated by the machinery. As previously mentioned, inside diameter (I.D.) size significantly affects how a flexible duct withstands negative pressure. However, another factor contributing to the performance level of suction hoses is the hose’s material composition. By understanding how negative pressure factors affect the choice of a suction hose, you can appropriately make a well-informed decision that increases the productivity and performance output of your vacuum units.

“PE Flex STM”

“PE Flex Translucent”

- Ideal for insulation blowing applications

- Easy to handle

- Translucent walls offer easy monitoring of material flow & blockage

The “PE Flex Translucent” material transfer hoses are a medium weight hose recommended for light bulk material handling applications. The clear hose material is constructed using translucent medium strength polyethylene. The flex duct wall has been reinforced with a translucent integral polyethylene helix, designed for moving dust and other light materials. The translucent flex duct walls are crush resistant and make it easy to monitor material flowing through the inside. The translucent coloration also makes finding clogs and blockages easy. The hose material is manufactured with FDA acceptable food grade materials.

Polyethylene is a preferred plastic that is used throughout the food packaging industry for its purity and non-toxic properties. It has a very simple molecular structure that does not require chemical additives (as opposed to vinyl/PVC and polyurethane material transfer hoses). The convoluted interior of this extraction ducting product creates efficient airflow that helps to aerate insulation materials. Material transfer hoses with this feature can increase machine efficiency with regard to coverage and density. The hose material is easy to handle and remains extremely flexible when used in both hot and cold working conditions.

What Is the Difference Between a Suction Hose and a Ventilation Hose?

The main differences between a suction hose and a ventilation hose is that one pulls ai and the other pushes air out. Suction hoses utilize negative pressure and a partial vacuum force to suck and extract materials from their source through the hose and to a collection area. On the other hand, ventilation hoses utilize positive pressure to push and blow materials from a collected source to another location. Keeping these functionalities in mind, the two hoses are designed with specific materials to suit their applications, with suction hoses catering to material extraction and collection and ventilation hoses catering to transferring and recirculation. You cannot use a ventilation duct for suction. It is not designed to handle the pressure and will fail.

While most flexible hoses and ducts are designed to handle both extraction and recirculation of air and materials, choosing a duct that can handle the positive and negative pressure generated from their intended machinery is important. If not, you risk installing a flexible duct to a piece of equipment not designed to perform effectively at its total capacity. An excellent example of this would be trying to use an air ventilation hose to extract grains from a silo; not only would the material cause significant wear and tear to the hose after a certain number of uses, but the ventilation hose would collapse in on itself due to the negative being applied. While the two types of flexible hoses are very similar, it is essential to understand the difference between suction and ventilation because it can ultimately affect how you move certain materials and what kind of flexible ducting you decide on.

“Smooth-Tube TPR”

“Smooth-Tube PU”

- External helix acts as wearstrip, protecting the outside of the hose.

- Excellent anti-microbial properties.

The “Smooth-Tube PU” material handling hose is a medium weight duct that is made up of polyurethane film. A great hose for dust collection and other material handling applications, it features a smooth interior that maximizes the level of flow in the tube. It is a very abrasion resistant hose thanks to its polyurethane makeup and its external wearstrip. Overall, this flexible ductwork is a great choice for your dust and material handling needs.

In addition to a resistance to physical damage, this hose also brings to the table other beneficial resistance properties. This flexible ductwork has a unique anti-microbial feature. It will not allow any mold, mildew, or other microbial byproducts to develop on the hose body. It is because of this feature that this is a good flexible hose for use in the fields of agriculture, lavatory waste disposal, peat moss vacuuming, and landfill venting.

This hose for dust collection is available to you in different size options. It is offered in standard lengths of 25 feet. You can choose from a selection of ID sizes ranging between 2 inches to 12 inches ID. This hose is also available in a variety of wall thickness from of 0.032, 0.033, 0.035, and 0.040 inches depending on the ID size. Regardless of the dimensions you choose, this hose will retain its excellent durability and flexibility.

What Is Full Vacuum Pressure?

Full vacuum pressure is often called a ‘perfect vacuum,’ which is the state where a space contains no matter or substance. On the inches of mercury scale, 29” IN/HG represents a perfect vacuum with highly dense atmospheric pressure. While creating or reaching a state of perfect vacuum is practically unlikely in residential and commercial settings, it is more achievable in industrial settings if operators utilize a small inside diameter hose. Due to the restrictive amount of space of a small inside diameter hose, the airflow is limited, creating a pressurized state that is more plausible and manageable to reach a full vacuum pressure. This is why most hose manufacturers produce small inside diameter hoses and ducting for industrial facilities and workshops: they possess the equipment and generate a large power output that can handle a state of perfect vacuum. As a result, flexible ducting options such as our polyethylene flex hose are designed to handle full vacuum pressure and ensure its users that whether they are extracting solid or liquid materials, the extracted material will be transferred quickly and efficiently.

“PE Flex Plus”

- Lightweight and flexible even at low temperatures

- Wet or dry vacuum in car wash, commercial, and industrial applications

“PE Flex Plus” vacuum hoses are recommended for wet or dry light bulk material handling applications. Each flex hose is constructed using a grey polyethylene copolymer material. The hose walls are then reinforced with an integral polyethylene helix that adds strength and abrasion resistance to the hose. Heavy-duty and commercial wet and dry vacuum applications need intense cleaning power; therefore more durable hoses are required. The “PE Flex Plus” is ideal flexible hose pipe for busy shops, industrial cleaning and more.

The polyethylene copolymer ducting material of this vacuum suction hose remains flexible even at low temperatures and has the ability to bend into tight spaces. Abrasion is the process of scuffing, scratching, wearing down, marring, or rubbing away the hose or other components. Abrasion is highly undesirable and can lead to premature wear and failure or the interior or exterior of the hose. The ducting material used in the “PE Flex Plus” offers extra protection against abrasion and crushing.

The “PE Flex Plus” is available in several ID sizes ranging from 1 inch to 4 inch. The vacuum hoses have a smooth interior for efficient air flow at any size. The flexible hose pipe is sold in grey and comes in standard lengths of 25 and 50 feet with plain cut ends. The smooth interior also helps reduce the chances of clogging or blocking.

“Smooth-Tube PVC”

Smooth Bore Hoses & Negative Pressure

Our “Smooth-Tube” flex hoses can handle negative pressure well due to their overall construction and design. Depending on your product choice, the medium-weight duct is reinforced with a rigid external helix made from either TPR, polyurethane, or PVC. Because of these designs, some of the sizes of our “Smooth-Tube” flex hoses can withstand a full negative pressures of 29” IN/HG.

The “Smooth-Tube” flex hose series are a superb option that can transfer materials from a source to a collection area. The lack of ridges and corrugations on the inside if the hoses allow for a smooth transfer. One of the main features of this flexible suction hose is its smooth interior design, stemming from its name, the smooth interior allows materials to flow easily through the duct and prevent any particles or debris from sticking inside. Should debris ever get clogged inside the flexible suction hose, operators would be able to detect the clog due to the clear, translucent design. This feature alone can save hours of maintenance downtime and scheduled repairs and allow operators to continue with their suction ducting applications. However, it is essential to note that the clear translucent color is only available in PVC and polyurethane versions of this product. So, if you are searching for a durable, abrasive-resistant flexible suction hose for your extraction ducting needs, you should consider the “Smooth-Tube” flex hoses.

“Smooth Tube PU”

“Smooth-Tube TPR”

- Completely smooth interior prevents clogs and maximizes airflow

- External helix acts as wearstrip, protecting the outside of the hose

- Available in flame retardant version

The “Smooth-Tube TPR” flexible hoses are medium weight hose products that are great for use in fume, light materials, dust and air movement applications. Each black rubber hose is made of thermoplastic rubber and has been reinforced with an exterior rigid polypropylene helix. A unique feature of this thermoplastic hose is its completely smooth interior. When hose and ducting materials have a smooth even interior, they greatly reduce the chances of clogs from occurring. The smooth interior helps to maximize airflow for efficient suction.

A very important feature to have in most ducting materials is flexibility and durability. Sometimes one or the other will do, but these flexible hoses combine both! In terms of flexibility, this hose is excellent. It can be bent and flexed with ease so that you can maneuver it into position wherever it is needed. Additionally, this hose is also very durable. The key behind its physical durability is the rigid polypropylene helix that is found along its outer body. This outer helix of the black rubber hose acts as an external wearstrip that serves to enhance the protection provided to this thermoplastic hose. The outer helix protects the hose against any external abrasion. An operator can drag this hose along a rough surface without worrying about it being damaged. As an added bonus, this flexible ducting is available in a flame retardant version.

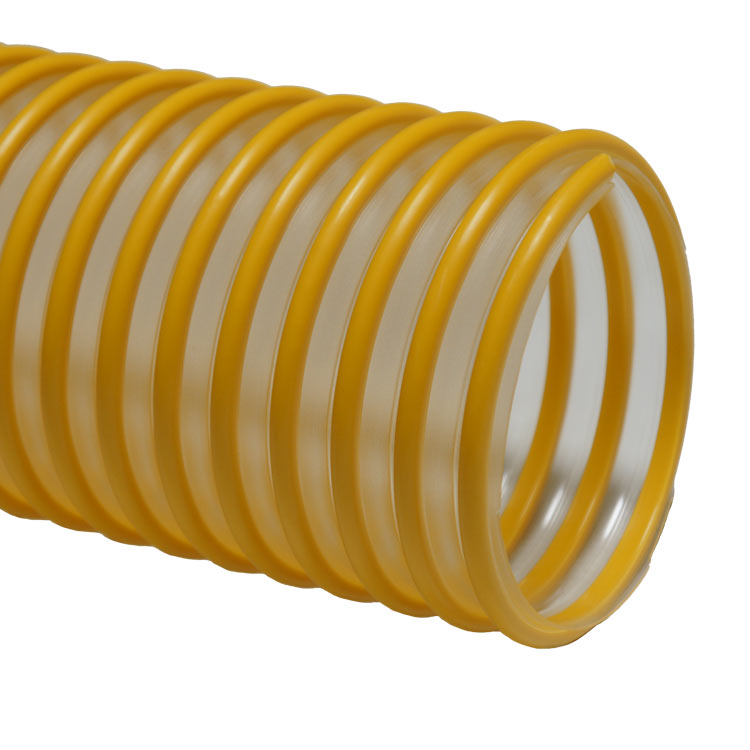

“PVC Flexduct Heavy-Duty”

“PVC Flexduct Medium-Duty”

“PVC Flexduct Heavy-Duty”

PVC Flex Duct- The Cost-Effective Alternative!

When looking for different ducting options for your extraction duct, cost is one of the most significant factors that can affect what you are searching for. “PVC Flex Ducts” is an affordable, cost-effective option that is great for general-purpose suction ducting and extraction. Entirely made from PVC plastic, “PVC Flex Ducts” is a popular lightweight choice for general industrial vacuum applications. These flexible ducts exhibit excellent chemical and moisture resistance, allowing operators to transfer various materials from general debris to liquids. The flexible duct’s construction is also designed to handle both positive and negative pressure applications, making it one of the most versatile flexible ducting options available. While a “PVC Flex Duct” is not as durable when directly compared to other flexible hoses made from materials such as polyurethane, polyethylene, or thermoplastic rubber, it stands as the most budget-friendly alternative.

“PVC Flexduct Medium-Duty”

- Construction allows for value packaging by reducing the box size, reducing warehouse space & shipping costs

- Ideal for dust and woodworking applications

- Manufactured with FDA acceptable materials

The “PVC Flexduct Medium-Duty” flexible hose is a medium-weight clear PVC wall hose reinforced with a spring steel wire helix for industrial air movement and light bulk material handling applications. PVC hose materials provide good compressibility and offer good chemical and moisture resistance. In addition, the spring steel wire helix featured on these duct materials provides extra protection. This flexible hose is great for applications where positive pressure will be present, as well as providing the user with an FDA or food grade acceptable material.

The “PVC Flexduct Medium-Duty” ducting has a working temperature range from -20 to +160 degrees Fahrenheit. The duct materials on this flexible duct hose allow it to be used in environments where the temperature range is slightly above ambient. This flexible duct hose also has great durability in outdoor environments. This medium-duty hose provides a great solution for industrial dust control and light bulk material handling. Also, the hose materials used in the construction of this product allows for great compressibility with little flex fatigue. This medium-duty hose has up to a four to one compression ratio.

“Urethane Flex Heavy-Duty”

“Urethane Flex Extra Heavy-Duty”

“Urethane Flex Heavy-Duty”

“Urethane Flex Medium-Duty”

Urethane Flex Hoses

Polyurethane flex ducts are viable for any vacuum suction hose application because of the hose’s material composition and overall design. Polyurethane is an extremely tough material with high tensile strength, making it one of the most superior synthetic rubbers for flexible ducting. While polyurethane flex ducts are known for their versatility as a reliable transfer duct, they are designed to handle both positive and negative pressure applications, making them ideal for a wide range of applications from abrasive material collection to standard ventilation. Our “Urethane Flex” hoses are available in different inside diameters (I.D.) sizes, lengths, colors, functions, and features. As a result, our “Urethane Flex” hose is one of the most popular and reusable transfer hoses for any application. Whether you are transferring grains or extracting abrasive trash and debris off the streets, a “Urethane Flex” hose is designed to withstand the most demanding and harsh environments for an extended period and serve as an excellent vacuum suction hose and transfer duct for whatever application you have in mind.

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Ideal for clean room and material plastic processing applications

- Surface resistance level: 108 – 1010 Ohms/Square

- Clear is manufactured with FDA acceptable materials

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.

Thermoplastic Rubber Hoses

When addressing which material is best suited for suction hoses, thermoplastic rubber is considered one of the most relied on due to its flexibility, durability, and affordability. Thermoplastic rubber has excellent resistance to fatigue, abrasion, moisture, U.V. rays, chemicals, and drag, all of which are necessary for a vacuum suction hose. These flexible hoses are often relied on as an affordable alternative to polyurethane flex ducts because polyurethane is generally more expensive, and thermoplastic flex ducts are just as durable due to the material’s composition. Much like a polyurethane flex duct, our thermoplastic flex duct is used in a myriad of applications across sectors. For instance, our “Thermoplastic Flex White” is an excellent material handling FDA-approved hose that is frequently utilized in agricultural and pharmaceutical applications and serves as one of the most reliable transfer ducts for their operators. Meanwhile, thermoplastic extraction ducts such as the “Thermoplastic Flex Medium-Duty” hose is an outstanding general-purpose duct that is consistently used in environments with extreme temperatures. No matter what kind of thermoplastic ductwork you decide on, it is reassuring to know that these transfer ducts are resilient enough to withstand a variety of external factors and environments without breaking the bank.

“Thermoplastic Flex Medium-Duty”

- Designed for wide temperature ranges while maintaining flexibility

- Great moisture and UV resistance

The “Thermoplastic Flex Medium-Duty” flexible hose is a great general all-purpose thermoplastic hose for medium-duty applications. This flexible hose is made from thermoplastic rubber. Thermoplastic rubbers are a class of copolymers that possess both thermoplastic and elastomeric properties, generally made from a mix of plastic and rubber. Thermoplastic rubber products have a successful track record in a wide range of automotive, industrial and commercial applications. These rubber hoses have reduced weight, lower costs, consistent performance, and are recyclable, unlike thermoset rubber compounds. Thermoplastic rubber ducts exhibit durability to extreme temperature and chemical exposure while offering excellent flexibility and abrasion resistance.

The “Thermoplastic Flex Medium-Duty” industrial ducts are made to operate at both high and low temperatures. This thermoplastic hose has a temperature range of -40 degrees to +275 degrees Fahrenheit, allowing it to be used in a wide variety of applications. The “Thermoplastic Flex Medium-Duty” rubber hose is made to order in both 25 and 50-foot sections. These thermoplastic industrial ducts are available in a wide variety of sizes in both inches and metric measurements (200 ft minimum for metric sizes). The standard internal diameter sizes for theses rubber ducts range from 1.5 to 24 inches and 60 to 300mm in metric measurements.