“Air Ventilator Black”

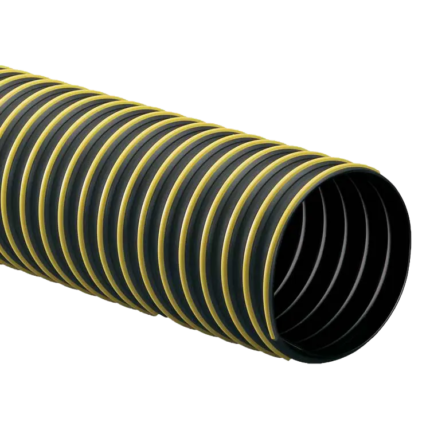

“Air Ventilator Orange”

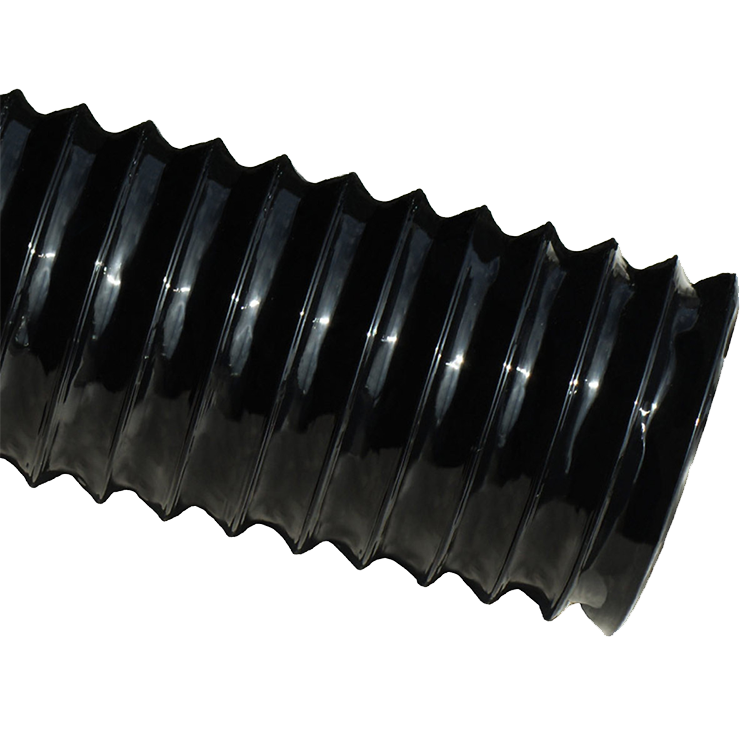

Tips Before You Buy: Why Does a Hose Need a Wearstrip?

Just as some ducting hoses resist internal abrasion, a wear-strip protects a hose from external abrasion. Hoses often see use in heavy-duty applications where they come into frequent contact with abrasive surfaces. Over time, abrasion degrades the hose walls, wearing out the hose. A wearstrip wraps around the hose’s exterior in a spiral, receiving any abrasion and allowing the hose walls to last longer.

Wearstrips are especially useful for ducting used in enclosed spaces, such as mining shafts. Air ventilators and material collection ducts extend the full length of the mine, and tend to be dragged along the ground or against the shaft’s walls when transported. Flex Ducts with wear-strips resist external abrasion also last longer, and are thus more useful for these kinds of heavy-duty applications.

A flex hose’s external wear-strip often follows the same path as the internal metal wire helix. Because of the wire’s weight, when a hose is dragged on the ground, the hose wall tends to receive the most abrasion near the wire helix. By following the same path as the wire helix, the wear-strip protects the part of the hose that wears out fastest.

“Spiral-Lock (Neoprene) 300”

“Spiral-Lock (Silicone 1P) 550”

“Tornado Flex Insulated AD”

“Wind Handler Insulated TU”

“Thermoplastic Flex Extra Light-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Thermoplastic Flex Super Reinforced”

Ducting Insights: Thermoplastic Rubber Ducts in the Outdoors!

Since outdoor temperatures vary throughout the day and from season to season, outdoor ducting hoses need to be able to withstand a variety of conditions to function long-term. As a result, ducting hoses made from thermoplastic are ideal for outside installation.

As their name suggests, thermoplastics are designed to handle both hot and cold temperatures. This allows these sturdy hoses to function at different times of the year, enduring the heat of summer and the chill of winter. For instance, the Thermoplastic Flex Medium Duty has an operating temperature range of -40º to +275º Fahrenheit. Thermoplastics are flexible, sturdy polymers, typically a combination of rubber and plastic. These waterproof materials allow thermoplastics to resist moisture from rain or other weather conditions.

Thermoplastic hoses have excellent resistance to other outdoor factors that can damage other ducting materials over time, such as UV light, ozone, and various chemicals. They also resist internal abrasion from common outdoor materials and debris. Light-duty thermoplastic hoses see use in dust collection or air ventilation, while heavy-duty thermoplastic hoses are often used to transport sand and gravel.

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

Leaf Vac Hoses

Perfect for suburban homes or mountain compounds both, mechanical leaf vacuum hoses are an excellent way to keep your property leaf-free. Everyone loves nature, and it is an understatement to say that trees add value to property. However, it is just reality that trees, bushes, and shrubbery of all varieties produce messy deposits of leaves, sticks, and other wooden refuse. That is why a good lawn vac hose can mean the difference between a clean and an enjoyable property versus a bedraggled one coated with rotting leaves.

The modern day leaf hose machine generally takes the form of a motorized, lawn tractor. These tractors can be operated much like a sitting lawn mower, that is to say, where the driver is perched on top of the machine and navigates it similarly to an automobile. Though they, of course, can come in all shapes and sizes, many lawn vac hose machines are powered by engines of up to 223 ccs and can hold roughly 200 gallons of leaf waste and other landscaping refuse. Some of the higher end models also feature steel impellers in the collection duct area of the tractor, which mulches up incoming debris and thereby increasing the total potential volume of the container massively while in use.

Probably the most critical component of any leaf vacuum worth its salt, however, is the lawn vac hose. Though they can come in several differing materials, polyurethane and rubber are two highly favored choices of consumers in the common, residential leaf hose market. Both of these materials are durable and long-lasting, and can withstand the multitude of damaging abrasives that leaf vacuum hoses face in their day-to-day operation. By installing a purposefully reinforced hose into the design of their mechanical leaf tractors, manufacturers are taking an important step in providing you –the consumer- with a lawn vac hose system you can rely upon for all your home landscaping and leaf removal needs.

When it comes to the leaf vacuum hoses and ducting themselves, it is critical that they be the proper size, in addition to being made from the necessary material. 8 inch duct is a commonly selected sizing of leaf hose because it is naturally capable of handling large amounts of refuse. There are few things worse than attempting to unclog a leaf-stuffed duct while in the midst of a busy landscaping project on a hot day. That is why it is so important to use an 8 inch duct (or larger) to ensure all your lawn vac jobs remain safe and efficient. As an aside, an 8 inch duct is compact enough to still produce maximum sucking power and ventilation. 8 inch leaf vacuum hoses really do make the best of both worlds.

If you are a homeowner, landlord, or resident who is tired of raking up pesky leaves by hand, seriously consider getting yourself a fully-operational leaf vacuum hose tractor. These tractors are purpose-built and designed to make tedious yard work as quick and enjoyable as possible. Know that when you use leaf vacuum hoses to handle all your leaf collection and disposal needs you are ensuring that your yard receives only the best and most thorough of care!

“Urethane Flex General Purpose Black”

- Great compressibility

- Good abrasion resistance

- Superior chemical resistance

The “Urethane Flex (General Purpose) Black” is a reliable and cost-effective flexible duct for light-to-medium grade applications involving air, dust, and materials transfer. Made from durable polyurethane, it is a black colored hose that exhibits superior compressibility, flexibility and abrasion resistance. The body of this polyurethane ducting is reinforced by a spring steel wire helix that acts to give the hose a sturdy physical build while also helping to improve its compressibility at the same time. The superior flexibility of this hose allows it to be used effectively in situations where the hose has to be bent at tight angles in order to reach more isolated areas. Compressibility is also another key feature of this flexible material handling hose because it allows the end user to store and transport the flexible duct with ease.

Applications involving the transfer of materials, from light dust to larger solid wood chips, can wreak havoc on the walls of most plastic hoses. Polyurethane is the ideal plastic material for use as a flexible material handling hose. The key factor is that polyurethane possesses a high rate of resistance against physical wear. It exhibits a longer lifespan in physically demanding situations. As an added bonus, polyurethane brings a high level of resistance to solvents such as oils and grease.

“Air Ventilator Heavy-Duty”

Best Sellers – Air Ventilator Hoses

Air ventilation hoses are designed with several different factors in mind. As such, these ducting hoses are very versatile products and have a huge number of potential uses. To boil it down to basics, the hose products are made to transfer air and facilitate circulation. But within that very broad definition, there is a huge number of applications that the hoses can be used for.

The Air Ventilator hose range is so versatile and effective because of the way the products are made. They are constructed from PVC rubber and vary in size from a 4-inch diameter to 24-inches, making them useful in every setting, from small-scale to industrial. The ducting is reinforced with a spring steel wiring that makes it extremely strong, even when flexed. It is also resistant to heat, standing up to a range of temperatures from -20 to 180 degrees Fahrenheit, while the Air Ventilator hoses can also compress to a fraction of their usual size. These hoses have a 10 to 1 compression ratio, meaning a 25 footer can compress to a 2.5ft size.

The range of applications for the Air Ventilator hoses are far-reaching. If there’s a need for air ventilation then this duct hose can fill it. That includes air conditioning, mobile and fixed chillers and dehumidification units. With the temperature resistance capabilities and the variety of sizes available, the hoses can be used in any setting, from an in-home HVAC system to large industrial machinery which needs ventilation tubing. While air flow – specifically in cold and heating systems – might be the primary use for the air ventilator hoses, they also have plenty of more obscure capabilities, such as a smoke ejector.

“Air Ventilator Insulated”

Ambient Air Ducting Articles

What Causes Black Dust on AC Vents?

Black dust on AC vents is caused by leaking ducts pulling in unfiltered air from dusty, dirty areas of your home. Because HVAC units cycle air, this unclean air adds extra sediment to your system. Even if your kitchen, bathrooms, and bedrooms are gleaming, your attic or in between your walls are probably not. Of course, you cannot do much to prevent dust from building up in these untouched areas of your house—hence, it falls upon your HVAC ductwork to compensate. If gaps or cracks in the AC-unit ductwork circulate inside your household, these leaks can pull dusty air from your ceiling or crawl spaces into the ducting. If air filters are the bouncers that prevent particles from entering or exiting the central air-conditioner duct-system, then dirty air sucked in from outside sources can be considered the uninvited gate-crashers, infringing on the process of HVAC. Dryer vent work—when it crosses by a leaky HVAC hose—can also be a source of dark-colored dust coming out of AC vents inside your home. Despite whether a dryer hose or a dusty attic is what causes black dust, the main issue is leaky AC ductwork. Not only do leaking ducts suck in unfiltered air, but they also reduce airflow inside your HVAC system, leading to uneven heating and cooling and an inefficient unit. Therefore, it is imperative to watch out for signs of leaky HVAC air-ducts—elevated energy bills, uneven HVAC, excessive dust levels, and more.

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Clear”

“PVC Flexduct General Purpose Blue”

“PVC Flexduct Light-Duty Clear”

All New

Aluminum Flex 280- Compressible

“Aluminum Flex 280 – Compressible”

- Designed for extreme temperature applications

- Resists metal fatigue, weathering, and most corrosive fumes and chemicals

The Aluminum Flex 280 – Compressible comes prefabricated in a variety of different inside diameter (I.D.) sizes: 3″, 4″, 5″, 6″, 8″, 10″, and 12″. The walls of this flexible metal tubing are 0.1 to 0.11 mm. thick, and it has an I.D. tolerance of 0 to 0.1 inch. Its end finishes are plain cut, and it comes in a classic, metallic-silver colorway. This flexible metal hose is also semi-rigid, which means that, once you bend it into a certain position, it will stay that way without any added support. Of course, you can bend it again to reform the duct into a different position. In sum, it’s likely that you will not need to use any accessories such as elbows to fit your Aluminum Flex 280 – Compressible into looping or bent positions.

This flexible metal duct is designed with air and fume ventilation applications in mind, thus making it well-suited for a variety of residential, commercial, and industrial applications—especially those that intend to transport high-temperature matter. Wood stoves, for instance, need to properly ventilate hot smoke from the wood they burn. The Aluminum Flex 280 – Compressible is a natural fit for these kinds of applications—especially since, oftentimes, a wood stove’s exhaust duct must navigate a circuitous pathway to reach the destination where it expels the stove’s fumes. Other common uses for this metal flex-duct include chemical fume ventilation, circuit board cooling, and air conditioner ducting, among other things.

How To Measure Ductwork

“Air Ventilator” Flexible Duct Series

Highly Compressible HVAC Ducts

“Air Ventilator Orange”

“Air Ventilator Yellow”

Are you searching for a flexible hose that can reliably transfer large volumes of air in an industrial setting? Our signature “Air Ventilator” series is a highly compressible, lightweight hose designed for large-volume air movement in indoor and outdoor applications. The “Air Ventilators” series is a coated poly-fabric flex hose dipped in a PVC vinyl coating and reinforced with a spring steel wire helix and protective external wear-strips, protecting it from external abrasive damage such as dragging and scraping. Most of these flexible hoses also come in a belted cuff end, making them extremely easy to install in machinery and utility blowers. Available in a multitude of colors, inside diameter (I.D.) sizes, lengths, and weight classes, our “Air Ventilator” series is a cost-effective ducting option that exhibits external abrasion resistance and a temperature range between -20 to +180 degrees Fahrenheit, making it an ideal ducting option that can withstand the rigors of industrial ventilation. If you are searching for a flexible hose that can cater to various ventilation ducting applications, then our “Air Ventilator” series is the right one for you!

“Air Ventilator Black”

“PVC Flexduct Light-Duty Clear”

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

Agricultural Hoses

The potential uses for heavy duty hoses when it comes to agricultural and resource cultivation concerns are practically limitless. Agricultural hoses are important to so many facets of these industries because of its ability to move plentiful and/or heavy material from one location to another, while conserving labor and energy. The flex tube itself is a revolutionary development within the agricultural ducting market. Having a length (or series of lengths) of agriculture hoses that can bend and move in varying ways has a laundry list of advantages over more immovable and inflexible ducts. From floor duct to gypsum transporters to fertilizer broadcasters, it is clear to see that potential agricultural hose implementations are only limited by the imagination of the consumer.

Farms and other resource cultivation areas exist for the sole purpose of generating and gathering the various products and material required for our modern day societal needs. According to www.agday.org, “Forty-one percent of the U.S. total land area is farmland (938.28 million acres). In 1900, the average farm size was 147 acres, compared to 441 acres today.” For reference, one acre is almost the size of a standard 100-yard American football field. With such massive amounts of agricultural land present in the United States (let alone the world as a whole), heavy duty hoses and ducts are perhaps now more important than they have ever been.

A primary use of agriculture hoses are for the purposes of functioning as a collection duct. Grains, feed, and wheat (all commonplace products on almost any given farm or ranch) all require short-and long-term storage. This is where the collection duct comes into play. Often made from rubber, polyurethane, or stainless steel, these kinds of agricultural hoses rely on either gravity or suction to absorb fallen grain and feed, and transport it to a suitable storage basin.

“Thermoplastic Flex White”

- Good abrasion resistance

- Designed for applications with wide temperature ranges

- Great moisture & UV resistance

The “Thermoplastic Flex White” is a medium-weight material handling hose that is great for abrasive, dust, and material collection applications. This product is specifically made from FDA acceptable hose material, which makes it suitable for food and drug-related applications. The thermoplastic rubber used in this product provides good chemical and heat resistance, and is also able to withstand higher temperatures than ordinary rubber products. Thermoplastic rubber refers to a class of copolymers that are made from a mixture of plastic and rubber. This combination results in a material that offers good chemical and UV resistance. This thermoplastic hose is also reinforced with a spring steel wire helix for added protection and stability. This resilient quality is important when using the food grade hose in rough and unforgiving environments. The smooth interior of this hose material allows for minimal friction loss and provides efficient airflow.

The “Thermoplastic Flex White” can be used as a dust collection hose in both high and low temperature environments. This thermoplastic hose has an operating temperature range of -40 degrees to +250 degrees Fahrenheit and is intended for environments that ordinary hoses cannot withstand. This product comes in a white color, which provides good visibility for food grade applications.