“Urethane Flex Medium-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Urethane Flex Light-Duty”

“Urethane Flex Heavy-Duty”

“Thermoplastic Flex Medium-Duty”

“Neoprene Flex Conductive”

“Urethane Flex Static Dissipative”

“Urethane Flex Self Extinguishing”

“Urethane Flex Extra Heavy-Duty”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex Heavy-Duty”

“Neoprene Flex – 2 ply Heavy-Duty”

“Neoprene Flex – 2 ply”

Screw Clamps

What Is Wood Dust?

Wood Dust, sometimes called ‘sawdust,’ is a byproduct of woodworking operations that utilize sawing, sanding, logging, milling, etc. Wood dust is mainly composed of fine particles and fibers such as cellulose (40-50%), polyose, lignin, and a sizeable number of substances depending on the type of wood. The production of sawdust is not limited to large-scale industrial settings. It is also a common byproduct of smaller-scale woodworking projects. Whether it is the crafting of elegant high-end furniture, the creation of durable wood flooring, or a fun DIY woodworking project, sawdust is an ever-present byproduct that can never be avoided. However, it is important to note that breathing in wood particles can bring about several health concerns, and it is essential to take necessary steps and precautions to prevent health problems.

Is Wood Dust Harmful?

Breathing in wood particles is a serious health hazard that can develop into a long-term chronic health condition, especially when faced with consistent prolonged exposure. According to OSHA, breathing in sawdust and all the fine particles within can cause serious health problems, such as allergic respiratory illnesses, cancer, dermatitis, and asthma. While our body’s immune cells do their best to prevent wood particles from reaching the deeper parts of the lungs, excessive inhalation of sawdust will overwhelm our body’s immune cells and will rot in our lungs and ultimately develop chronic health problems such as fibrosis of the lung tissue which can impair lung function. Due to sawdust’s harmful composition on our respiratory systems, numerous safety laws and standards have been enforced to protect those who face constant exposure to wood particles and anyone who might encounter it by chance. Prop 65, for example, is a California law that requires businesses to provide warnings to Californians about significant exposures to chemicals and materials that can cause cancer, congenital disabilities, and other reproductive harm. By requiring that this information is provided, Proposition 65 enables Californians to make informed decisions about their exposure to chemicals and allows them to take certain safety precautions when working with or in an environment that exposes them to these chemicals. Safety measures such as wearing masks during woodworking projects are one of the many safety precautions that should be taken. Whether you constantly encounter wood particles or not, it is crucial to know the five dangers of sawdust: Respiratory problems, Skin irritation, Eye irritation, Fire/Explosions, and Slips/Trips. By being aware of both the environmental and health risks of wood particles, we can properly limit our exposure and prevent any saw dust-related injuries from occurring.

“Urethane Flex Light-Duty”

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Ideal for clean room and material plastic processing applications

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.

“Thermoplastic Flex Heavy-Duty”

“Thermoplastic Flex Medium-Duty WS”

“Thermoplastic Flex Medium-Duty”

Can Inhaling Wood Dust Cause Permanent Damage?

Inhaling wood dust for long periods can cause permanent damage to one’s respiratory system, especially with prolonged or repeated exposure. The extent of the damage is dependent on several factors, such as the type of wood particles, the concentration levels, and the duration of exposure. According to OSHA, the permissible exposure limit for sawdust particles is set at 5 milligrams per cubic meter of air over an eight-hour average. Depending on the type and density of sawdust, wood particles can linger in the air for about 30 minutes, and if not cautious enough, it can develop early symptoms such as shortness of breath, dry and sore throat, constant sneezing and tearing, and eye inflammation. However, in severe cases of wood dust inhalation, long-term respiratory conditions such as bronchitis, chronic obstructive pulmonary disease, and lung fibrosis can develop and significantly impair lung capacity and functions. Most notably some types of wood chips increase the risk of nasal and sinus infections, and if not treated properly, it can lead to the development of sinus and nasal cancer. As a result, all safety measures and precautions must be taken to prevent developing long-term diseases. If you are worried about your exposure to wood particles, there are several ways to alleviate the symptoms and exposure risk, such as moving to an area with fresh air and thoroughly rinsing your eyes and skin with clean water. However, if you are exhibiting chronic symptoms of wood dust inhalation or if your conditions are worsening, it is important to seek medical attention as soon as possible.

“Thermoplastic Flex Super Reinforced”

- Combines the ozone, UV, weathering, and chemical resistance of thermoplastic rubber with the tensile strength and fatigue resistance of fabric hoses

- Offers the better tear strength, puncture, & abrasion resistance than traditional reinforced woven neoprene & thermoplastic hoses

- Handles higher positive pressures than non-reinforced thermoplastic rubber hose

The “Thermoplastic Flex Super Reinforced” is a reinforced material handling hose designed for heavy-duty applications that require more abrasion resistance than ordinary thermoplastic flexible ducts. This rubber hose is unique because its hose material is a combination of thermoplastic rubber and non-woven polyester fabric, which makes it more durable and resistant than similar duct hoses. The thermoplastic material gives this rubber hose greater chemical, ozone, and weathering resistance, while also providing a longer life in extreme hot and cold environments. Due to its non-woven polyester fabric reinforcement, this thermoplastic hose is also more resistant to tearing, punctures, and abrasion. The thermoplastic hose is reinforced with a spring steel wire helix that gives this hose even more protection and durability. This product is specifically made for heavy-duty applications involving abrasives and materials.

How Do I Keep My Wood Shop Dust-Free?

The best way to keep a wood shop and any woodworking environment dust-free is by utilizing a dust collection system. A dust collection system is a device used to improve air quality in industrial, commercial, and residential settings by collecting dust and other impurities from the air. Dust collection systems can come in many styles and designs, from simple portable units to complex stationary systems. However, no matter what kind of dust collection system you purchase, they will all function similarly by the three main actions: capture, convey, and collect. The process begins with capturing dust at its source, and once the sawdust is captured, it is transported through the machine’s ductwork and to the filtration unit, where it collects and accumulates dust in a designated area such as a bin, bag, or hopper. There are two different types of dust collection systems: Single-Stage and Double-Stage. Single-Stage dust collection systems are a one-hose system that sucks up wood particles like a vacuum, and the dust is filtered through an impeller chamber that separates the dust particles and wood chips and places them in two separate bags for disposal. Meanwhile, Double-Stage dust collection systems utilize a “cyclone” system that draws air into a separator, where wood chips fall into a bag, and the dust particles are blown upwards to a filtration system where all the ultra-fine particles are captured, and the system exhaust filtered air back into the room. While a woodshop vacuum is considered a more affordable alternative to all your sawdust collecting means, a woodshop shop vacuum is neither as strong nor as effective as a saw dust collector. Depending on your application, different types of dust can be produced during woodwork, so it is important to find a wood dust collection system and a wood dust collection hose suited for your needs.

“Poly Fabric Flex – 1 Ply”

- Wearstrip offers additional external abrasion & drag resistance

- Available without a wearstrip for a more economical option

- Additional coatings available for better abrasion &/or chemical resistance

The “Poly Fabric Flex – 1 ply” is a single-ply PVC vinyl coated polyester fabric hose reinforced with a spring steel wire helix & external PVC wear-strip. This hose provides efficient airflow and is recommended for industrial air movement and fume control applications. The durable and flexible industrial ducting material provides great chemical and moisture resistance while the reinforced spring steel wire helix and external PVC wear-strip offer great external abrasion and drag resistance. This class of abrasion resistant material handling hoses is ideal for industrial fume control applications that have an exposure to harsh environments. These durable flex ducts are also very cost-effective.

The “Poly Fabric Flex – 1 ply” flex ducts have a working temperature of –20 to +180 degrees Fahrenheit. This will provide the user with an air duct that can be used in environments operating at above or below ambient temperatures. Furthermore, this product is listed as UL 94 V-0 flame retardant and can be used where safety is a concern. This flexible industrial ducting has excellent flow characteristics with low friction loss because of the smooth internal structure. This quality provides you with material handling hoses that will help with the prevention of clogging. The interior of the flex ducts allows for efficient movement of light objects.

Anti-Static Duct Hose – A Woodworking Necessity

Anti-static dust hoses are crucial in choosing a wood dust collection hose, especially when handling dry wood chips and other similar materials. Static dissipative hoses are coated with a conductive elastomer, which helps reduce the danger of static buildup by allowing electrostatic buildup to escape. This is particularly important for wood dust collection because if you are collecting dry wood chips, friction can develop between dust particles and the dust collection system’s flexible ducting, and if the wood chips happen to ignite in the process, the entire system and wood chips will explode and cause a severe hazard. Considering that all woodworking ducts and facilities are surrounded with flammable material, sudden sparks pose a serious threat and problem for every woodworking shop in every setting. Beyond safety means, static dissipative hoses can also contribute to the efficiency of woodshop dust collection systems. Static buildup can cause dust particles to cling onto the flex hose’s interior, enough dust particles will eventually be stuck to each other to impede the flex hose’s airflow and reduce the system’s overall effectiveness. Additionally, static discharges can damage the electronic components of the dust collection system and fry the entire system. By using static dissipative flex hoses, you can protect your dust collection system and ensure that the chances of your woodworking ducts and facilities catching on fire are minimal.

“Neoprene Flex Conductive”

- More durable than double-ply cotton hoses

- Surface Resistance Level: 103 to 105 Ohms/Square

The “Neoprene Flex Conductive” static dissipative hose is recommended for industrial air movement, fume control, dust control, and light bulk material handling applications. The flex ducting is made from double-ply, neoprene coated polyester fabric that has been coated with a conductive elastomer. Flexible ducts with higher conductivity help reduce the danger of static buildup by allowing any electrostatic buildup to escape. If the net charges grow faster than a material can dissipate them, an electrostatic charge builds up. The excess charge can suddenly neutralize by a flow of charges to the surroundings, known as an electrostatic discharge or static spark. By super-heating the surrounding air and causing it to rapidly expand, the discharge is both visible and audible.

The neoprene coating of the hose material offers excellent abrasion and chemical resistance and is designed for abrasives, air, dust fumes and other materials. Each commercial hose is reinforced with a spring steel wire helix for good crush resistance and tensile strength. This product can handle both positive and negative pressure, please refer to the hose specification sheet for test data on specific sizes. This static dissipative hose has a working temperature range of -40 to +250 degrees Fahrenheit.

“Urethane Flex Self Extinguishing”

- Halogen-free

- Great abrasion resistance & high tear strength

- Manufactured with flame retardant materials

The “Urethane Flex Self Extinguishing” material handling hose is a medium-weight wall hose made with a self-extinguishing polyurethane material great for severe abrasive, dust, and material movement. The polyurethane hose materials used in this product gives it excellent chemical, abrasion resistance, and high tear strength. Polyurethane flex ducts exhibit the best abrasion resistance and are recommended in applications that demand a durable flex ducting. This material handling hose exhibits superior flex fatigue and is recommended for applications that require continuous flexing. This product is available in FDA acceptable materials and allows for its use in applications involving the movement of foods, grains, and pharmaceuticals.

This flex ducting works in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The “Urethane Flex Self Extinguishing” hose is made of Halogen-free flame retardant hose materials. Halogens (Flourine, Chlorine, Bromine, Iodine, Astaline) are salt formers. This is especially for the electronics industry that has an interest in products assembled without the use of these elements in the raw materials.

“Neoprene Flex – 2 Ply”

What Kind of Duct Should I Use for Dust Collection?

Ideally, you should use a flex duct that is sturdy and durable enough to handle the transfer of abrasive materials commonly found in wood dust. Flex ducts such as “Neoprene Flex” hoses are among the best due to their coating and accessibility to different styles, types, and functions. “Neoprene Flex” hoses are made from neoprene-coated polyester fabric, and due to the polymerization of chloroprene of neoprene, “Neoprene Flex” hoses exhibit high tensile strength that is exceptionally resistant to abrasion and chemicals, and depending on your choice of products feature other types of resistance and functions such containing a flame-retardant design, degradation resistance, and even a static dissipative function. These flexible hoses come in standard 25-foot lengths and can come in various sizes, and depending on your application, you can even order custom ID sizes that can go up to 60 inches. As a result, a “Neoprene Flex” hose is a highly dependable flex duct that is an excellent option for a woodworking hose for your wood dust collection system.

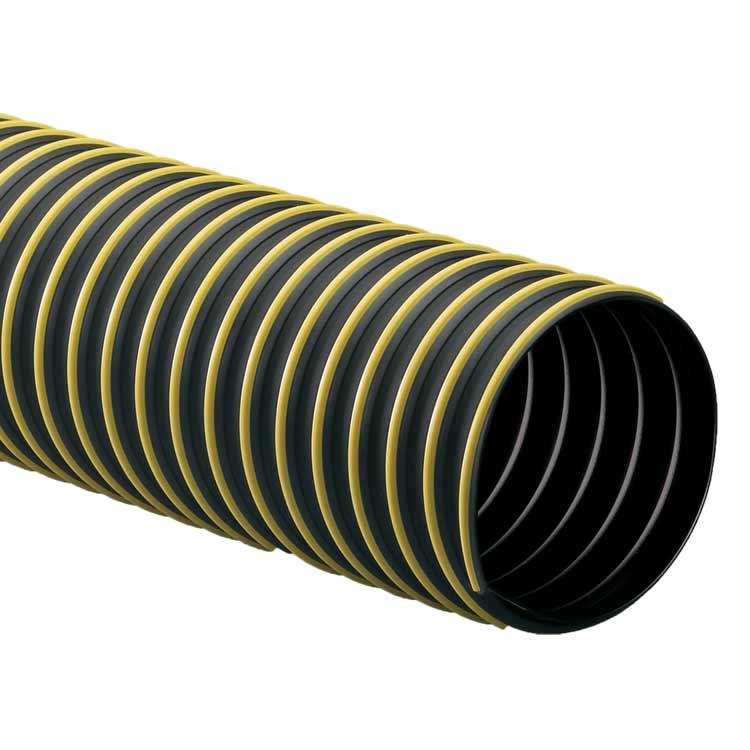

“Neoprene Flex – 2 Ply Heavy-Duty”

- Handles both positive and negative pressure

- Available with an external wearstrip

The “Neoprene Flex – 2 ply HD” is a heavy-duty hose recommended for light bulk material handling applications. Each flexible duct is made from double-ply neoprene coated polyester fabric, making for a thick walled hose that offers excellent flexibility. The material handling hose is then reinforced with a spring steel wire helix. This flexible hoses spiral design is made to withstand abrasive dust and other harsh materials. The neoprene and polyester construction of the “Neoprene Flex – 2 ply HD” offers superior abrasion resistance and excellent flex life. Neoprene resists degradation more than natural or other synthetic rubbers. This relative inertness makes it well suited for demanding applications.

The material transfer ducts have a high strength to weight ratio that is augmented by excellent flow characteristics. The “Neoprene Flex – 2 ply HD” material handling hose can handle both positive and negative pressure and has a working temperature range from -40 to +250 degrees Fahrenheit. This hose can be ordered with an external wear-strip in cases where abrasion on the exterior of the hose is possible. Also, an additional neoprene coating can be added for better abrasion and chemical resistance. The additional coating and added wear-strip can extend the life of this material handling hose in demanding environments.

“Urethane Flex Heavy-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Self Extinguishing”

“Urethane Flex Static Dissipative”

“Urethane Flex General Purpose Black”

“Urethane Flex Extra Heavy-Duty”

Urethane Wood Dust Collection Hose – Excellent Abrasion Resistance

“Urethane Flex” ducts are robust, durable option in material handling ductwork and wood dust collection. “Urethane Flex” ducts are flexible polyurethane hoses composed of polymer and carbamate (urethane) links known for their elasticity, transparency, and resistance to chemicals, extreme temperatures, oils, and solvents. These flexible ducts are available in several styles and can be purchased in a minimum of 12ft and up to 50 foot lengths. We inventory popular styles, ID sizes and colors of this hose. “Urethane Flex” ducts are available in several thicknesses and as the product gets a thicker wall, its flexibility lessens as their wall thickness and abrasion resistance increases. While this may seem disadvantageous, having a flexible hose with a thick wall means these flexible ducts are built to last in the most arduous environments. This line of hoses is available in black, blue or clear colors and in an anti-static and a self-extinguishing version. The Urethane-Flex serious of hoses are the premier option when abrasion resistance is top priority.

“Urethane Flex Small ID”

- Excellent abrasion resistance

- Lightweight and flexible

- Good chemical resistance

The “Urethane Flex Small ID” dust collection hoses are lightweight material handling hose made of polyurethane and are excellent for air, dust, fume, and material applications. The polyurethane duct material used in this product makes it extremely flexible and also provides great chemical and abrasion resistance. A unique feature of this hose is available in smaller internal diameters, as low as half-inch ID! This hose is designed as a small diameter material collection duct. It is designed to exhibit the same durability and flexibility that larger ID products have but in a smaller hose.

The “Urethane Flex Small ID” flexible duct is designed for applications that move abrasives and solid materials. This material handling hose works in temperatures ranging from a low of -60 to a high of +160 degrees Fahrenheit. While this urethane flex hose has a lower temperature resistance than other “Urethane Flex” hoses, this product is also offered in much smaller internal diameter options. This flexible duct is a far better option that standard small diameter tubing. It has better flex fatigue, offers excellent compression, and maintains its radius when bent! The duct material used to produce these dust collection hoses gives them excellent chemical resistance and life when exposed to UV rays.

Smooth-Tube Series – No More Clogs!

The ducts in the “Smooth-Tube” series are durable air ducts with ample wall thickness that protect these hoses from physical damage, such as external objects or abrasive media traveling through the hose. A unique feature of this flexible hose series is its completely smooth interior, whereas most flexible hoses are designed with corrugations; abrasive materials such as wood chips will get stuck between corrugations and eventually create a buildup within a flexible hose. However, the “Smooth-Tube” series is specifically designed to prevent that from occurring, making it especially handy for wood chip ducting. In addition, the “Smooth-Tube” series is available in different materials and designs, such as thermoplastic, polyurethane film, and PVC, which gives you various options depending on your application. While “Smooth-Tube” flex ducts are a more expensive alternative than other options, they are particularly effective in applications where you are expected to handle a variety of abrasive materials. If you are looking for a reliable, flexible duct for your wood dust collection system, our “Smooth-Tube” series should be considered for all your wood chip ducting and woodshop ductwork needs.

“Smooth-Tube TPR”

“Smooth-Tube PU”

- Highly abrasive resistant, smooth interior hose.

- Excellent flexibility and puncture and crush resistant.

- External helix acts as wearstrip, protecting the outside of the hose.

- Excellent anti-microbial properties.

The “Smooth-Tube PU” material handling hose is a medium weight duct that is made up of polyurethane film. A great hose for dust collection and other material handling applications, it features a smooth interior that maximizes the level of flow in the tube. It is a very abrasion resistant hose thanks to its polyurethane makeup and its external wearstrip. Overall, this flexible ductwork is a great choice for your dust and material handling needs.

Consider carefully the benefits of having a smooth interior on a flexible hose for material handling. A smooth interior area means that the hose does not have any uneven ridges or corrugations. Such uneven surfaces can invite finer materials to get caught inside and clog up the flex duct. This can be a huge problem that will hinder the efficient functioning of your application. Particles will not get caught or form clogs on smooth interior surfaces of this hose due to its smooth bore. Inside, the material handling hose will benefit greatly from a superior and efficient level of airflow.

“Thermoplastic Flex Medium-Duty”

“Thermoplastic Flex Super Reinforced”

“Thermoplastic Flex Heavy-Duty”

Thermoplastic Rubber Flexible Ducts

When choosing a flexible hose for your wood dust collection system, there is no better option than “Thermoplastic Flex” hoses. “Thermoplastic Flex” hoses are among some of the most durable flex hoses for a wood dust collection system because of the material that they are made from. Made from thermoplastic rubber, the material is derived from a class of copolymers with thermoplastic and elastomeric properties, a unique mix of rubber and plastic. As a result of their material, “Thermoplastic Flex” hoses can withstand extreme temperatures and showcase a longer life span than standard flexible hoses in environments with extreme temperatures. Depending on your application and machinery requirements for your wood dust collection system, “Thermoplastic Flex” hoses come in different weight classes, builds, and featured designs that can suit a number of applications. If you are looking for a flexible hose designed to withstand the pressures of abrasive ducting and wood chip ducting, then “Thermoplastic Flex” hoses are the one.

“Thermoplastic Flex Medium-Duty WS”

- Great general all-purpose hose

- Designed for applications with wide temperature ranges

- Smooth interior assures minimal friction loss and efficient air flow

“Thermoplastic Flex Medium-Duty WS” is a thermoplastic rubber duct designed as a great general-purpose material, air, dust or fume handling hose. This product is unique from other thermoplastic rubber duct products because it features an external wear-strip that offers additional external abrasion protection and drag resistance. The external wear-strip extends the product life by protecting the hose from external wear, which is often forgotten by end-users. This is one of our best selling products!

Thermoplastic rubbers are a class of copolymers that possess both thermoplastic and elastomeric properties, generally made from a mix of plastic and rubber. The thermoplastic rubber material gives this rubber hose great chemical resistance and also provides a longer life in extreme hot and cold environments over standard rubber. Thermoplastic vulcanizates (TPVs) have been proven to be dependable polymers for flexible engineered parts that require long-term performance. This hose is recommended for applications that require good chemical and abrasion resistance, such as dust and abrasives collection.

Quality Dust Collection Ducts – A Must for any Woodworking Facility

Ultimately, the best kind of hose for your wood dust collection system will depend on your needs and applications; however, “Thermoplastic Flex” hoses and “Urethane Flex” ducts will offer the most options for your plans. Whether you have a Single-Stage or Double-Stage wood dust collection system, it is essential to find a flexible hose that correctly matches these systems to get the best results. If you do not utilize an effective wood dust collection hose, you risk exposing yourself to potentially inhaling excessive wood particles. As a result, you run the risk of developing long-term respiratory diseases, such as bronchitis, chronic obstructive pulmonary disease, and lung fibrosis. It is also essential to utilize a static dissipative flex hose for your wood dust collection system to prevent environmental hazards such as fires and explosions from occurring. As productive as you can be in your woodworking shop, maintaining a clean and hazard-free environment is just as important to produce the best woodworking projects imaginable.

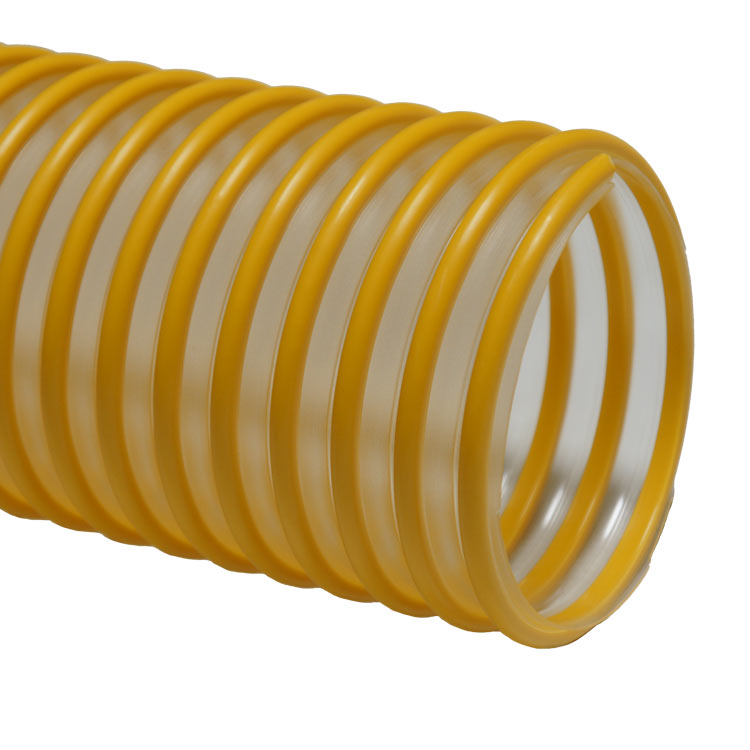

“Urethane Flex Heavy-Duty”

- Designed for applications with wide temperature ranges

- Ideal for severe service applications

- Very good low temperature flexibility

The “Urethane Flex Heavy-Duty” material handling hoses are designed to work in severe abrasive and material transfer applications. This flex duct is made from polyurethane duct materials, making it very durable and flexible. The diverse properties of polyurethane make it the leading choice for engineers looking for long-lasting materials for their high load, high stress environments. Polyurethane routinely outperforms plastic and rubber in its overall ability to resist harsh environmental factors such as abrasion, heat, solvents, oil and acid. Because of the PU material used in these material handling hoses, these products feature fantastic tear strength while maintaining excellent flexibility.

This flex duct is also available in a clear color that is made with FDA acceptable materials. This flexible ducting’s heavy wall makes it an ideal choice for heavy-duty applications involving abrasives. The “Urethane Flex Heavy-Duty” material handling hoses are designed to work within wide temperature ranges. This dust collection hose works in temperatures ranging from -65 to +225 degrees Fahrenheit. Even when working in low temperatures, this dust collection hose maintains excellent flexibility.