“Urethane Flex Extra Heavy-Duty”

“Urethane Flex Heavy-Duty”

“Urethane Flex Light-Duty”

“Urethane Flex Medium-Duty”

“Urethane Flex Self Extinguishing”

“Urethane Flex Static Dissipative”

Screw Clamps

A Quick Intro to Polyurethane

Polyurethanes were invented in the 1930s by Professor Dr. Otto Bayer. Although he worked for IG Farben and later was on the advisory board of the Bayer Corporation, Otto Bayer was not related to the founding family of Bayer Corporation.

The use of PU flourished during World War II, since most of the natural rubber supply was produced in the Southern Hemisphere and when the German rubber supply was cut during World War II the widespread use of polyurethanes spiked. PU became a replacement for rubber, which at this time was more expensive to produce.

Polyurethane is an inert and chemically neutral material. Polyurethane refers to a class of polymers composed of organic units joined by carbamate (urethane) links.

Polyurethane often abbreviated PU refers to a class of polymers composed of organic units joined by urethane links. Polyurethane can be produced from a wide range of starting materials. This chemical variability yields PU grades that have different structures producing parts for a varied list of applications. There are lots of types of polyurethanes, with appearances and elasticity that are completely different from one other. But the basic chemistry of each type is essentially the same. Polyurethane is a plastic material, which exists in various forms like rigid and flexible foams, coatings, adhesives, and fibers such as spandex and polyurethane laminate. It can be tailored to be either rigid or flexible.

“Urethane Flex Light-Duty”

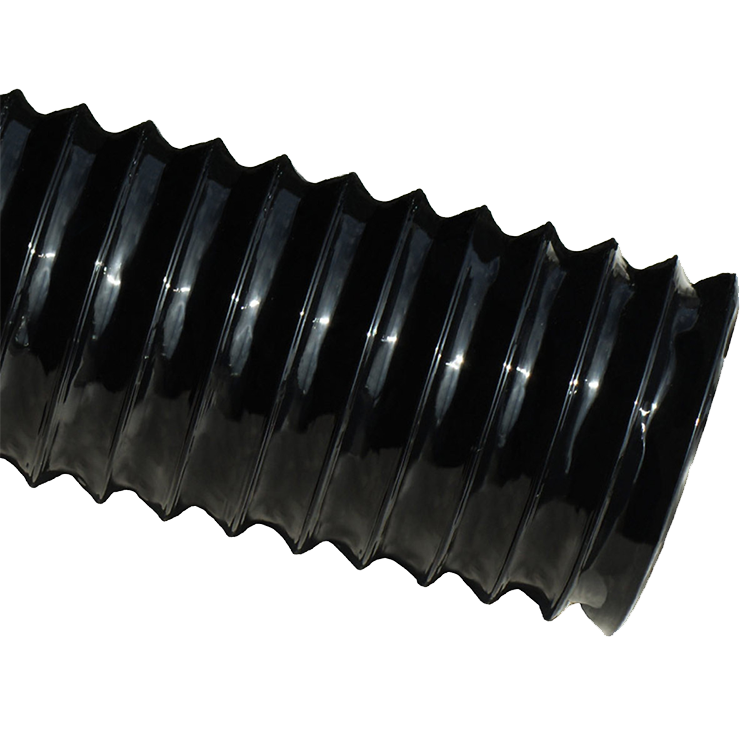

“Urethane Flex Heavy-Duty”

- This hose is in stock in 4”, 6” and 8” ID sizes and can ship in 24hours

- Great abrasion resistance & high tear strength

The “Urethane Flex Heavy-Duty” material handling hoses are designed to work in severe abrasive and material transfer applications. This flex duct is made from polyurethane duct materials, making it very durable and flexible. The diverse properties of polyurethane make it the leading choice for engineers looking for long-lasting materials for their high load, high stress environments. Polyurethane routinely outperforms plastic and rubber in its overall ability to resist harsh environmental factors such as abrasion, heat, solvents, oil and acid. Because of the PU material used in these material handling hoses, these products feature fantastic tear strength while maintaining excellent flexibility.

This flex duct is also available in a clear color that is made with FDA acceptable materials. This flexible ducting’s heavy wall makes it an ideal choice for heavy-duty applications involving abrasives. The “Urethane Flex Heavy-Duty” material handling hoses are designed to work within wide temperature ranges. This dust collection hose works in temperatures ranging from -65 to +225 degrees Fahrenheit. Even when working in low temperatures, this dust collection hose maintains excellent flexibility.

What is a Polyurethane Hose Used for?

Polyurethane hoses are used to move bulk materials, dusts, and abrasives. Here are 14 reasons to use PU flexible Ducting:

1- Better than Rubber and Plastics

Polyurethane ducts can handle impact and abrasion like rubber but have the flexibility of PVC. Polyurethanes have outstanding ability to withstand more loads than rubber because they are harder than rubber and yet more flexible than plastics. Their flexibility is accountable for their strength and remarkable ability to resist impact.

2-Better Abrasion Resistance

Polyurethanes are the perfect choice for applications against severe wear regardless of temperature. PU hoses are the go-to products for material handling and abrasive transfer applications. No other form of thermoplastic, rubber, metals, or plastics have a better abrasion resistance than polyurethanes. Their abrasion resistance ability is rated to be 10 times better than what other materials can provide.

3-Excellent Oil and Chemical Resistance

Polyurethane hoses are able to oil and chemicals. This enables them to maintain stability when faced with oils or other harsh chemicals.

4-Affordable

Production of PU ducting and hoses are not any costlier than competitive products. This makes them a more durable product only marginally more expensive and when comparing the work life of PU hoses to that of rubber or other thermoplastics, polyurethane material handling ducts are by far and clearly the more affordable long term investment.

5- Overall Resilience

Resilience is generally a product of hardness. Polyurethanes are the perfect choice for elastomer applications that can absorb shock. They have a high vibration frequency or outstanding ability for quick recovery. Their remarkable resilience ensures polyurethanes are very tough materials.

6- Available in FDA grades

The availability of an FDA grade hose allows of the use of PU flex ducts in the transfer of grains and food materials.

7- Static Dissipative options

Static dissipating urethane makes it possible to use hose in woodworking, grain handling or other applications that can cause static buildup. This feature of a static dissipative duct makes it possible to operate without the worry of possible explosions and fires.

8- Available in Clear or Black

Stocked products in a variety of colors allow for end-users to choose amongst the color options.

9- Chemically Inert

Thanks to the fact that it is an inert material, it is not affected by humidity as mentioned above, nor does it favor the proliferation of fungi, bacteria, molds or other organisms.

10- Moisture and Rot Resistant

Since it is not affected by moisture, it is rot-resistant, and stable

11- It is odorless

This is prized in specific applications that require an aromatically inert product

12- Excellent in outdoors

It has longer life when used as a material handling hose in outdoor or extreme environments

13- Harder than Rubber

PU has harder durometer ranges without sacrificing performance or flexibility

14- Superior cut and tear resistance

Superior abrasion, cut, and tear resistance allows for it use in truly abusive applications like street sweeping and construction clean up

“Urethane Flex Medium-Duty”

What is PU Ducting?

PU ducting is polyurethane ducting and PU is an acronym for polyurethane. PU Ducting is a class of flexible hoses that have great abrasion resistance & high tear strength and are designed to move materials and abrasive dust. PU Ducting’s superior chemical resistance and excellent flexibility mark the PU flexible hose at the top of its class. With a temperature Range of -65°F to 225°F polyurethane flexible hoses are designed for applications with wide temperature ranges especially due to their very good low temperature flexibility. The clear colored version of PU ducting is manufactured with FDA acceptable materials. In addition, length customization is available with factory installed soft cuffs. PU Ducting is available in I.D. sizes (inches) from 1.25 to 24-Inch Inside Diameter.

“Urethane Flex Light-Duty”

- Great compressibility

- Great abrasion resistance

The “Urethane Flex Light-Duty” is a lightweight flexible polyurethane hose designed for air, dust, and light material applications. This product is made from polyurethane hose materials and is recommended for industrial air movement, fume control, and dust collection applications. The polyurethane wall and spring steel wire helix reinforcement gives the “Urethane Flex Light-Duty” excellent compressibility, abrasion resistance, and chemical resistance. This ultra flexible dust collector hose is the thinnest walled polyurethane hose we offer. The thinner wall permits this polyurethane hose to have excellent compression ratio (5 to 1), lower weight per linear foot, and great flexibility.

One of the main advantages of polyurethane components is their excellent resistance to wear in both sliding and impact abrasion. Polyurethanes have excellent resistance to fuel, oils, grease, and many solvents. This makes them especially suited for applications such as automotive, steel and aluminum manufacture, and printing. These lightweight hoses are available in a black or clear flexible hose colors. The clear version is made from FDA acceptable materials. A clear flexible hose also allows operators to see clogs, which makes for a perfect woodworking dust collector hose! The “Urethane Flex Light-Duty” lightweight hoses are built with hose materials that allow them to work in a wide range of temperatures from a low of -65 to a high of +225 degrees Fahrenheit.

“Urethane Flex General Purpose Black”

- Great compressibility

- Good abrasion resistance

Applications involving the transfer of materials, from light dust to larger solid wood chips, can wreak havoc on the walls of most plastic hoses. Polyurethane is the ideal plastic material for use as a flexible material handling hose. The key factor is that polyurethane possesses a high rate of resistance against physical wear. It exhibits a longer lifespan in physically demanding situations. As an added bonus, polyurethane brings a high level of resistance to solvents such as oils and grease.

This wire-reinforced hose is available in most popular internal diameter (ID) sizes ranging from 2” to 12” and is available in standard lengths of 12ft and 25ft. The ends of this flexible duct are plain cut, so the end user has the ability to use clamps of their preference to attach them to their intended outlets. One very distinguishing feature of this polyurethane ducting is its ability to operate in temperatures ranging from -65° F to 225° F, a trait that is lacking in many of its competitors. This general purpose flexible material handling hose is the perfect option for applications such as leaf collection, chemical fume extraction, hull sanding equipment, wood dust collection, and cold/hot air supply.

Is a Polyurethane Hose Better Than a Rubber Hose?

PU flexible hose are better than rubber hoses when used in material handling applications like leaf and litter collection, wood dust transfer or fertilizer broadcasting applications. Polyurethane exhibits better abrasion resistance and tear strength. Abrasion resistance is a material’s ability to withstand wear as it faces friction. The more friction an application encounters the quicker the part will deteriorate. The chemical composition of a material will determine how easily it wears when abraded.

Why polyurethane instead of rubber? We offer Polyurethane duct products that exhibit the high-quality characteristics of PU products. Polyurethane has excellent abrasion resistance and will outperform rubber and plastic sometimes by a factor of as much as 5 to 1. For applications in which wear is a problem, switching to polyurethane flexible hoses can reduce the frequency of replacement. This means less down time and greater productivity from your flexible hose investment. The material make-up of our Polyurethane duct products makes them extremely resistant to external abrasions without sacrificing their flexibility. This means that these hoses are a great choice for applications that require the plastic ducting to be easily maneuverable and not damaged by outside abrasive materials. For added protection, the Polyurethane duct products are also resistant to UV light and Ozone damage. This all-around great weather resistance means that your PU hose can be utilized in outdoor applications such as water transportation, irrigation, or sewage removal.

“Urethane Flex General Purpose Black”

What is the Most Abrasion Resistant Hose?

Polyurethane is the preferred duct or hose when there are abrasive materials being transferred. An example of abrasive materials that may need to be cleaned up or directed to storage can be wood chips/dust, trash, road debris, construction rubble, sand, bulk foods, grains, and the list is endless. As these media are being moved, they will have a negative effect on the equipment used to moved them, through abrasion, tearing, gouging, and scraping. Therefore, the physical spaces and routes that are used to move the materials are considered “wear surfaces” or wear parts. Material and abrasives handling ducting is one such wear part. These hoses are made flexible and durable so as to extend their lives in the field. These are the non-permanent parts of the machinery. They are expected to have shorter life cycles and to be replaced, possibly seasonally. One cost associated with wear parts like material handling ducts is the cost of the hose and should be based on their life expectancy. Another important cost is the downtime of the machinery and the labor costs associated with replacing a material handling duct. For example, if a hose is not in stock at the operators’ site, every day that your equipment is inoperable is a day that you are not productive and possibly not generating revenue. Polyurethane hoses are the most dependable and most abrasion resistant hoses in the market and are the best option for firms trying to reduce machinery stoppage.

“Urethane Flex Small ID”

- Lightweight and flexible

- Good chemical resistance

The “Urethane Flex Small ID” dust collection hoses are lightweight material handling hose made of polyurethane and are excellent for air, dust, fume, and material applications. The polyurethane duct material used in this product makes it extremely flexible and also provides great chemical and abrasion resistance. A unique feature of this hose is available in smaller internal diameters, as low as half-inch ID! This hose is designed as a small diameter material collection duct. It is designed to exhibit the same durability and flexibility that larger ID products have but in a smaller hose.

The “Urethane Flex Small ID” flexible duct is designed for applications that move abrasives and solid materials. This material handling hose works in temperatures ranging from a low of -60 to a high of +160 degrees Fahrenheit. While this urethane flex hose has a lower temperature resistance than other “Urethane Flex” hoses, this product is also offered in much smaller internal diameter options. This flexible duct is a far better option that standard small diameter tubing. It has better flex fatigue, offers excellent compression, and maintains its radius when bent! The duct material used to produce these dust collection hoses gives them excellent chemical resistance and life when exposed to UV rays.

Screw Clamps

“Urethane Flex Static Dissipative”

Is a Polyurethane Hose Better Than a Thermoplastic Duct?

For material handling and the movement of bulk materials and abrasives, polyurethane material handling hose is more durable than a thermoplastic duct. When competing against conventional thermoplastic rubbers, polyurethane ducts boast a higher durometer range. In numerous applications, the replacement of traditional thermoplastic ducts with polyurethane hoses has proven to be a game-changer. Industries ranging from leaf collection to street sweeping have embraced the transition, reaping benefits in terms of enhanced performance and longevity. Polyurethane also is available in variety of thicknesses that allow the operators to choose based on flexibility, budget and wall thickness. Polyurethane is also available in clear or black. Clear allows the end-user to monitor materials as they travel through the hose and inspect for possible blockages and dust buildup.

“Urethane Flex Self Extinguishing”

- Good compressibility

- Great abrasion resistance & high tear strength

The “Urethane Flex Self Extinguishing” material handling hose is a medium-weight wall hose made with a self-extinguishing polyurethane material great for severe abrasive, dust, and material movement. The polyurethane hose materials used in this product gives it excellent chemical, abrasion resistance, and high tear strength. Polyurethane flex ducts exhibit the best abrasion resistance and are recommended in applications that demand a durable flex ducting. This material handling hose exhibits superior flex fatigue and is recommended for applications that require continuous flexing. This product is available in FDA acceptable materials and allows for its use in applications involving the movement of foods, grains, and pharmaceuticals.

This flex ducting works in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The “Urethane Flex Self Extinguishing” hose is made of Halogen-free flame retardant hose materials. Halogens (Flourine, Chlorine, Bromine, Iodine, Astaline) are salt formers. This is especially for the electronics industry that has an interest in products assembled without the use of these elements in the raw materials.

“Urethane Flex Heavy-Duty”

Is a Polyurethane Hose Better than a PVC or Vinyl Hose?

When used in the movement of dust, materials or abrasives, PU ducting will last far longer than a PVC or vinyl duct hose. PVC is a far more affordable option and is only a better choice when used to move air. Since PU is more expensive, it is a better choice for commercial or industrial applications, whereas PVC maybe a budgetary choice for homeowners and less invasive projects.

ASTM International defines wear as “damage to a solid surface” involving gradual damage to materials, caused by the relative friction between a surface material and a contact material. Abrasion is the action that causes wear while wear is removal of a portion of the surface by some kind of mechanical action. There are byproducts of abrasion – sliding and impingement.

Sliding is the passing of an adjacent surface across the rubber surface. Impingement is wearing of the rubber exemplified by sand particles hitting the surface. Most wear in actual service occurs as a combination of both sliding and impingement.

Wear resistance, a key attribute, holds the key to meeting these demands. It is the ability of a material to withstand the effects of abrasion, friction, and mechanical wear over time. Achieving and evaluating wear resistance is not a trivial task; it requires precise measurement techniques and advanced testing equipment. The Taber Abrasion Testing Machine serves as a vital tool in accurately measuring wear resistance.

Polyurethane ducts often outwear corresponding hoses made of PVC, vinyl, vinyl coated fabrics or thermoplastics, by a wide margin. Polyurethane hoses withstand the typical forms of abrasion extremely well like sliding, impingement, and slurry. PU flexible ducting resist the tearing associated with sliding abrasion and absorb and recover from the particle impacts associated with abrasion.

“Urethane Flex Static Dissipative”

- Great abrasion resistance & high tear strength

- Superior chemical resistance & excellent flexibility

The “Urethane Flex Static Dissipative” material handling hose is a medium-weight wall hose featuring an electrostatic discharge resistant surface. The electrostatic resistant surface allows this product to reduce static buildup when handling materials. This is especially useful in applications when static buildup can result in explosions or accidents. In addition to the static resistant surface, the polyurethane used in this product gives it excellent chemical and abrasion resistance and high tear strength. The spring steel wire helix provides extra support and durability. These flex hoses are built with a medium weight construction, making it ideal for medium-duty applications with abrasives, dust, and materials. This flex duct is great for woodworking and grain handling applications.

The “Urethane Flex Static Dissipative” material ducting hose is constructed to work in a wide range of temperature applications. This product is designed to work in temperatures ranging from a low of -65 to a high of +225 degrees Fahrenheit. The high temperature tolerance, electrostatic discharge resistance, chemical resistance, and tear strength qualities given by the hose materials make this a great flex duct for most abrasive environments.